Small manufacturing businesses are the backbone of many economies, driving innovation and providing specialized products. However, as these agile operations grow, they inevitably face a common and often crippling challenge: managing inventory across multiple warehouse locations. What starts as a simple, single-site operation can quickly evolve into a complex network of storage facilities, each holding different raw materials, work-in-progress (WIP) components, or finished goods. This increasing complexity, if not managed effectively, can lead to significant inefficiencies, financial drain, and even stagnation. The key to unlocking sustained growth and profitability in this scenario lies in adopting the right technological solution, specifically ERP for Small Manufacturing: Managing Multiple Warehouse Inventories. This comprehensive guide will explore how an Enterprise Resource Planning (ERP) system can transform these operational headaches into strategic advantages.

The Complexities of Manufacturing and Multi-Warehouse Management

The journey from a single humble workshop to a thriving multi-warehouse manufacturing enterprise is fraught with intricate challenges. For many small manufacturers, the initial expansion often feels like a triumphant leap, but it also introduces an entirely new layer of operational complexity, particularly when it comes to inventory. Imagine having raw materials stored in one location, components in another, and finished goods distributed across several regional depots to serve various customer bases. Each of these locations holds a piece of the puzzle, and without a unified, coherent system, that puzzle quickly becomes a tangled mess.

The traditional methods that worked for a single site – spreadsheets, manual tracking, or disparate software tools – simply cannot cope with the exponential increase in data and interdependencies that arise from multiple warehouses. This fragmentation leads to a lack of visibility, where decision-makers struggle to get a clear, accurate, and up-to-date picture of their entire stockholding at any given moment. This absence of a single source of truth often results in costly missteps, impacting everything from production schedules to customer satisfaction, and ultimately, the manufacturer’s bottom line and growth potential.

Why Small Manufacturers Struggle with Dispersed Inventory

For small manufacturers, the leap from one to multiple inventory locations often happens organically, driven by growth in sales, diversification of product lines, or strategic geographic expansion. However, this growth can quickly expose the limitations of existing inventory management practices. One of the most common pain points is the sheer difficulty of maintaining accurate stock counts across various sites using manual methods or disconnected software. Teams in different warehouses might use different nomenclature for the same item, or updates might not propagate in real-time, leading to a distorted view of available stock.

This fragmented approach invariably leads to a cascade of problems. Stockouts, where a critical component or finished product is unavailable despite being present in another warehouse, can halt production lines or delay customer orders, damaging reputation and incurring expedited shipping costs. Conversely, overstocking occurs when excess inventory is purchased or produced due due to an inability to see the full picture of what’s already on hand across all locations. This ties up valuable capital, incurs storage costs, and increases the risk of obsolescence, especially for products with short shelf lives or rapidly changing designs. These issues directly hinder a small manufacturer’s agility and competitiveness in a demanding market.

The Core Promise of ERP for Small Manufacturing

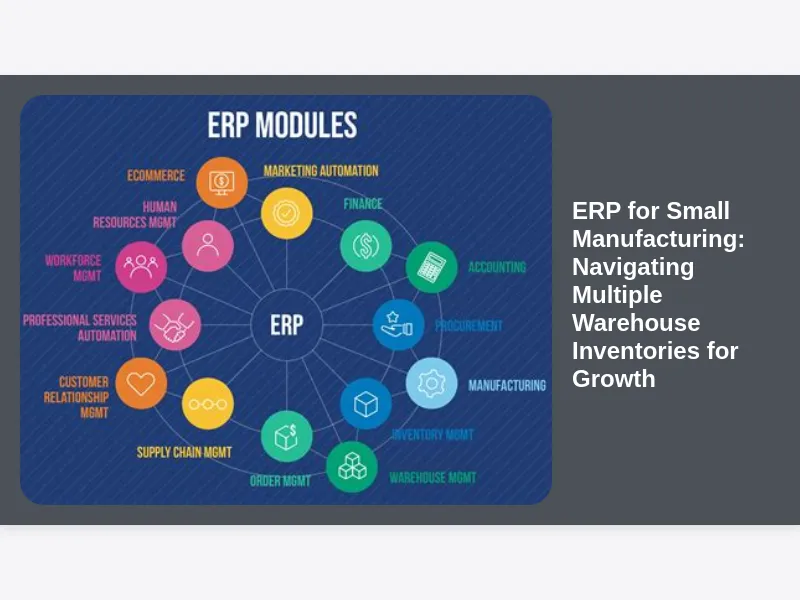

At its heart, an Enterprise Resource Planning (ERP) system is an integrated suite of business applications that centralizes data and automates processes across an entire organization. For small manufacturing firms, particularly those wrestling with multi-warehouse inventory, the core promise of ERP is transformative simplicity. Instead of numerous disparate systems, spreadsheets, and manual notes, an ERP system consolidates all critical business functions – from procurement and production to sales and inventory – into a single, unified database. This creates a “single source of truth” for all operational data.

This centralization is particularly powerful for managing multiple warehouses. It means that an item scanned into one warehouse is immediately visible across the entire organization. A sales order placed can automatically check stock levels in all relevant locations, and a production plan can draw an accurate picture of available raw materials regardless of their physical storage point. The beauty of ERP lies in its ability to connect these dots, providing a holistic view that empowers smarter decision-making, streamlines workflows, and significantly reduces the potential for costly errors that plague fragmented systems. It shifts small manufacturers from reactive problem-solving to proactive, data-driven strategy.

Unpacking the Benefits: Real-time Inventory Tracking Across All Locations

One of the most compelling advantages of implementing ERP for Small Manufacturing: Managing Multiple Warehouse Inventories is the invaluable capability of real-time inventory tracking. Imagine being able to see, at any given moment, the precise quantity, location, and status of every single item, whether it’s a raw material, a work-in-progress component, or a finished good, across all your warehouses. This level of granularity and immediacy eliminates the dangerous guesswork and delayed updates that are common with manual or disjointed systems.

With an ERP, every transaction – receiving new stock, moving items between warehouses, issuing materials to production, or shipping a finished product – is recorded instantly and reflected across the entire system. This means that a sales representative can confidently promise delivery dates based on actual available stock, a purchasing manager can place orders only when truly needed, and a production supervisor can allocate materials knowing they are physically present. This real-time data flow drastically improves accuracy, reduces the risk of costly stockouts or overstock, and provides a clear, actionable picture of your global inventory, allowing for truly informed and agile business decisions.

Optimizing Warehouse Operations: Beyond Just Counting Stock

The power of an ERP system extends far beyond merely knowing what you have and where it is; it fundamentally optimizes the very operations within each warehouse. For small manufacturers managing multiple sites, this means transforming chaotic storage spaces into efficient, well-oiled machines. ERP systems offer advanced functionalities that help streamline internal warehouse processes, improving throughput and reducing the time and labor required for tasks like receiving, putting away, picking, and packing.

Imagine a system that intelligently suggests the optimal storage location for newly arrived goods based on their size, frequency of use, or batch number. Furthermore, when an order comes in, the ERP can generate optimized picking routes, guiding staff through the warehouse in the most efficient sequence, minimizing travel time and errors. It can also manage cycle counting, directing periodic inventory checks to specific locations or items to maintain continuous accuracy without disrupting full operations. By providing tools for location management, serial number tracking, and batch control, ERP empowers small manufacturers to not only count their stock accurately but to manage it with precision and strategic intent across all their distributed facilities.

Enhanced Production Planning with Integrated Inventory Data

For small manufacturing businesses, the efficiency of their production line is directly tied to the availability of materials. Delays caused by missing components or raw materials can be incredibly costly, leading to idle machinery, unproductive labor, and missed delivery deadlines. This challenge is magnified exponentially when inventory is spread across multiple warehouses. An ERP system seamlessly integrates inventory data directly into the production planning module, creating a powerful synergy that optimizes manufacturing schedules.

With a comprehensive ERP, production planners gain real-time visibility into current stock levels across all locations, as well as inbound shipments. This allows them to create master production schedules (MPS) and material requirements planning (MRP) with unprecedented accuracy, ensuring that all necessary components are either on hand or planned to arrive precisely when needed. The system can automatically generate purchase orders for depleted stock, or even suggest transferring materials between internal warehouses to meet immediate production demands. This integrated approach minimizes production stoppages, reduces lead times, and allows small manufacturers to maximize their output and honor their commitments with greater reliability.

Achieving End-to-End Supply Chain Visibility for Small Manufacturers

True efficiency in manufacturing, especially for operations with multiple warehouses, hinges on having complete visibility across the entire supply chain. This means understanding not just what’s currently in your warehouses, but also what’s in transit from suppliers, what’s committed to production, and what’s on its way to customers. For small manufacturers, achieving this end-to-end perspective with traditional tools is nearly impossible, leading to blind spots that can cause significant disruptions and missed opportunities.

An ERP system acts as the central nervous system for your supply chain, pulling data from various touchpoints – procurement, inventory, production, sales, and logistics – into a unified view. This means you can track raw materials from the moment they leave your supplier’s facility, through their arrival and storage in your diverse warehouses, through their consumption in production, and finally, as finished goods, through their distribution to your customers. This holistic visibility allows small manufacturers to proactively identify potential bottlenecks, anticipate delays, mitigate risks, and make more informed decisions about sourcing, production, and distribution, ultimately building a more resilient and responsive supply chain.

Streamlining Order Fulfillment: From Sale to Shipment Across Warehouses

The process of fulfilling customer orders can become incredibly complex when a small manufacturer operates with multiple warehouses, each potentially holding different stock levels of various products. Without a centralized system, sales teams might promise products that aren’t readily available, or warehouse staff might struggle to determine the optimal shipping location, leading to delays and increased shipping costs. ERP for Small Manufacturing: Managing Multiple Warehouse Inventories directly addresses these challenges by transforming order fulfillment into a streamlined, automated process.

An ERP system intelligently automates the entire order-to-shipment workflow. When a sales order is entered, the system can instantly check stock availability across all your warehouses, automatically allocating items from the location that offers the quickest delivery or most cost-effective shipping route. It can then generate precise picking lists, packing slips, and shipping labels, ensuring accuracy and efficiency for warehouse personnel. This not only significantly speeds up the order fulfillment cycle but also reduces errors, optimizes logistics costs, and most importantly, enhances customer satisfaction by ensuring timely and accurate deliveries from the most appropriate distribution point.

Cost Reduction and Profitability: The Financial Impact of Efficient Inventory Management

At the core of any business decision lies the potential for financial impact. For small manufacturing firms, particularly those juggling multi-warehouse inventories, the implementation of an ERP system directly translates into significant cost reductions and a boost in overall profitability. The inefficiencies inherent in fragmented inventory management – stockouts, overstocking, and operational errors – all come with a hefty price tag that erodes margins. An ERP system systematically tackles these issues, turning them into opportunities for savings.

By providing real-time accuracy and optimized stock levels, ERP drastically reduces carrying costs associated with excess inventory, such as storage fees, insurance, and obsolescence write-offs. It minimizes the need for costly expedited shipping by ensuring products are where they need to be. Furthermore, precise demand forecasting, powered by integrated sales and inventory data, enables more strategic purchasing, often leading to better negotiation power with suppliers and reduced material costs. Every saved dollar from these efficiencies directly contributes to the small manufacturer’s bottom line, freeing up capital that can be reinvested into growth, innovation, or other critical business areas, making the investment in ERP a clear driver of financial health.

Scalability and Growth: How ERP Supports Expanding Manufacturing Operations

For any small manufacturing business, growth is the ultimate objective. However, without the right foundational systems in place, growth can quickly become a curse rather than a blessing. Expanding into new markets, introducing new product lines, or adding more warehouses can overwhelm existing, inadequate systems, leading to operational chaos and hindering further progress. This is where the inherent scalability of ERP for Small Manufacturing: Managing Multiple Warehouse Inventories proves invaluable.

An ERP system is designed to grow with your business. When you decide to add a new warehouse, it’s not a matter of installing a whole new, separate system; it’s simply configuring the existing ERP to include the new location. The unified database effortlessly incorporates additional data, users, and processes without sacrificing performance or data integrity. This means that as your manufacturing operations expand, whether through increased production volume, geographical diversification, or a broader product portfolio, your ERP system can seamlessly accommodate these changes. It provides a stable, robust, and extensible platform upon which sustained and ambitious growth can be built, preventing your technology from becoming a bottleneck to your future success.

The Challenge of Data Accuracy: A Cornerstone of ERP Success

While an ERP system offers incredible power and efficiency, its true value is inextricably linked to the accuracy of the data it processes. For small manufacturing businesses managing multiple warehouse inventories, the challenge of data accuracy is amplified. Garbage in, garbage out – this adage holds particularly true for ERP. If the information entered into the system is incorrect or incomplete, the sophisticated reports, forecasts, and automated actions the ERP provides will be flawed, leading to poor decisions and operational missteps that can undermine all the benefits.

An effective ERP system, however, is designed to enforce data integrity. It achieves this through standardized data entry fields, validation rules, and robust process flows that minimize human error. For instance, serial number tracking ensures that individual units are uniquely identified and accounted for, while batch tracking can follow specific groups of items through their lifecycle. Regular cycle counts and physical inventories, when integrated with the ERP, help reconcile discrepancies and maintain accuracy. The commitment to meticulous data input and consistent adherence to system processes across all warehouses is not just good practice; it is the absolute cornerstone upon which the success and reliability of your multi-warehouse ERP solution depend.

Cloud-Based ERP Solutions: Accessibility and Affordability for Small Businesses

Historically, ERP systems were often associated with massive upfront investments, extensive IT infrastructure, and dedicated teams for maintenance – resources that were largely out of reach for small manufacturing businesses. However, the advent of cloud-based ERP solutions has dramatically democratized access to this powerful technology. For small manufacturers, particularly those navigating the complexities of multi-warehouse inventories, cloud ERP offers unparalleled accessibility and affordability, making it a highly attractive option.

Cloud ERP, often delivered as Software-as-a-Service (SaaS), eliminates the need for substantial hardware purchases and ongoing IT maintenance. The vendor hosts and manages the software and infrastructure, allowing the manufacturer to access the system via a web browser from anywhere, at any time. This significantly reduces upfront capital expenditure and converts it into predictable monthly operational costs, making it a much more financially viable option for smaller firms. Furthermore, cloud solutions typically include automatic updates and robust security features, ensuring small manufacturers always have access to the latest functionalities and their data is protected, all without needing a large in-house IT department. This flexibility and cost-effectiveness make cloud ERP an ideal enabler for efficient multi-warehouse management in the small manufacturing sector.

Navigating ERP Implementation for Small Manufacturing Firms

The decision to adopt an ERP system is a significant strategic move for any small manufacturing business, and its successful implementation is crucial, especially when dealing with the intricacies of multiple warehouse inventories. The process might seem daunting, but with careful planning and execution, it can be smoothly navigated. It begins long before any software is installed, with a thorough assessment of current processes, identification of pain points, and a clear definition of desired outcomes and key performance indicators (KPIs) for multi-warehouse management.

Key steps typically involve selecting the right vendor and solution, which aligns with the specific needs of managing distributed inventory. This is followed by detailed planning, including data migration from legacy systems (a critical and often complex task), system configuration to match unique business workflows, and rigorous testing across all warehouse scenarios. Crucially, extensive user training is essential to ensure that employees in every warehouse understand how to use the new system effectively. Overcoming resistance to change and fostering user adoption across all locations is paramount, requiring strong leadership and clear communication throughout the entire implementation journey. A well-executed implementation lays the groundwork for realizing the full potential of ERP for Small Manufacturing: Managing Multiple Warehouse Inventories.

Selecting the Right ERP Vendor: Key Considerations for Multi-Warehouse Needs

Choosing the correct ERP vendor and solution is arguably the most critical step in harnessing the power of ERP for Small Manufacturing: Managing Multiple Warehouse Inventories. The market is flooded with options, and not all ERP systems are created equal, particularly when it comes to supporting the specific demands of a multi-warehouse manufacturing environment. Small manufacturers must approach this selection process with diligence, focusing on a few key considerations to ensure the chosen solution is a perfect fit.

Firstly, industry expertise is paramount. Does the vendor truly understand the nuances of small manufacturing, including production planning, inventory complexities, and supply chain dynamics? Look for a solution with robust multi-location inventory management capabilities, including features for inter-warehouse transfers, real-time stock visibility across sites, and location-specific inventory rules. Scalability is another vital factor; the system should be able to grow with your business as you add more warehouses or product lines. Furthermore, evaluate the vendor’s support structure, implementation methodology, and commitment to long-term partnership. Request comprehensive demonstrations that showcase multi-warehouse scenarios relevant to your business, and don’t hesitate to ask for references from similar-sized manufacturers who manage distributed inventory. A thorough vetting process will ensure you invest in a solution that genuinely empowers your unique operational needs.

Measuring Return on Investment (ROI) from Your ERP System

Implementing an ERP system, even a cloud-based one designed for small manufacturers, represents a significant investment of time, resources, and capital. Therefore, understanding and measuring the Return on Investment (ROI) is crucial to justify the expenditure and demonstrate the tangible benefits of ERP for Small Manufacturing: Managing Multiple Warehouse Inventories. While some benefits, like improved decision-making, can be qualitative, many others are quantifiable and directly impact the bottom line.

Manufacturers should establish clear KPIs before implementation to track improvements post-ERP. These might include reductions in inventory carrying costs due to optimized stock levels, decreases in stockout occurrences, shorter order fulfillment cycles, and fewer shipping errors across multiple warehouses. Quantify savings from reduced manual labor, less redundant data entry, and decreased administrative overhead. Track improvements in production efficiency and reductions in wasted materials. Over time, these measurable gains, combined with the strategic advantages of enhanced scalability and improved customer satisfaction, will paint a clear picture of the substantial ROI delivered by a well-implemented ERP system, showcasing its direct contribution to the company’s financial health and competitive edge.

Beyond Inventory: The Integrated Benefits of ERP Across the Enterprise

While the primary focus for small manufacturers with distributed operations might be on ERP for Small Manufacturing: Managing Multiple Warehouse Inventories, it’s crucial to recognize that an ERP system’s true power lies in its comprehensive, integrated nature. Inventory management, as vital as it is, is just one piece of a much larger, interconnected puzzle that an ERP expertly solves. The real magic happens when inventory data seamlessly flows into and impacts other critical business functions, creating a truly unified operational environment.

Consider how accurate, real-time inventory data directly informs your accounting department by providing precise cost of goods sold (COGS) figures and inventory valuation. Sales teams benefit immensely from knowing exact product availability, enabling them to make realistic promises and process orders efficiently. The procurement department leverages demand forecasts and current stock levels to optimize purchasing, while production planning becomes far more agile and responsive with a clear view of material availability. By integrating these disparate functions, an ERP system eliminates data silos, improves cross-departmental collaboration, and provides a holistic view of the business, empowering better strategic decisions that transcend individual operational areas and foster overall enterprise efficiency.

Common Misconceptions and Addressing Skepticism about ERP

Despite the clear advantages, many small manufacturers approach ERP with a degree of skepticism, often rooted in common misconceptions. One prevalent belief is that ERP systems are “too expensive for small businesses,” harking back to a time when they primarily served large enterprises with massive budgets. Another common concern is that ERP is “too complex to implement” and will disrupt current operations beyond recovery. Finally, the comfort of familiarity often leads to the argument, “we’re doing fine with spreadsheets and our current system,” overlooking the hidden costs of inefficiency and the limitations on growth.

It is important to directly address these concerns. Modern cloud-based ERP solutions have significantly lowered the barrier to entry, offering subscription models that make them financially accessible to smaller firms. Furthermore, many vendors now specialize in solutions tailored for small manufacturing, simplifying implementation and providing industry-specific functionalities that streamline the process. While any significant technological change requires effort, the long-term gains in efficiency, accuracy, and scalability far outweigh the initial challenges. Continuing with fragmented systems often means incurring significant hidden costs in wasted time, inaccurate data, missed opportunities, and the inability to effectively manage something as critical as ERP for Small Manufacturing: Managing Multiple Warehouse Inventories, ultimately hindering the very growth small businesses strive for.

The Future of Manufacturing: Embracing Digital Transformation with ERP

The manufacturing landscape is undergoing a profound digital transformation, often referred to as Industry 4.0. This era is characterized by smart factories, the Internet of Things (IoT), artificial intelligence (AI), and advanced analytics, all working together to create highly efficient, agile, and responsive production environments. For small manufacturers, staying competitive in this evolving ecosystem is paramount, and an ERP system is not just a tool for current efficiency, but a foundational platform for embracing this future.

An ERP acts as the central nervous system that collects, processes, and disseminates data from across the entire manufacturing operation, including multiple warehouses. This centralized data hub becomes essential for leveraging emerging technologies. For instance, IoT sensors on machinery or within warehouses can feed real-time performance or environmental data directly into the ERP. AI can then utilize this rich dataset for more precise demand forecasting, predictive maintenance, or even optimizing inventory placement across distributed locations. By integrating these advanced capabilities, ERP for Small Manufacturing: Managing Multiple Warehouse Inventories transforms from a mere management tool into a powerful enabler of continuous innovation and strategic growth, positioning small manufacturers at the forefront of the modern industrial revolution.

Conclusion: Empowering Small Manufacturing with Intelligent Inventory Management

The journey of a small manufacturing business is one of continuous evolution, marked by the ambition to grow and the challenge of managing increasing complexity. For those navigating the intricate web of multiple warehouse inventories, the path to sustained success and profitability hinges on intelligent, integrated management. Manual processes, disconnected spreadsheets, and disparate software solutions simply cannot keep pace with the demands of today’s dynamic market, leading to costly errors, operational bottlenecks, and stifled potential.

Implementing a robust ERP system fundamentally transforms these challenges into opportunities. It provides the essential framework for real-time visibility across all locations, optimizes warehouse operations, enhances production planning, and streamlines order fulfillment. By centralizing data and automating critical processes, ERP empowers small manufacturers to achieve significant cost reductions, improve data accuracy, and build a scalable foundation for future expansion. The investment in ERP for Small Manufacturing: Managing Multiple Warehouse Inventories is not merely an expense; it is a strategic imperative that equips businesses with the agility, efficiency, and insight needed to thrive in a competitive landscape, turning operational complexity into a powerful lever for growth and enduring success.