Small manufacturers often operate in a landscape defined by fierce competition, evolving customer demands, and the constant pressure to innovate while keeping costs in check. The dream of bringing a product from concept to market efficiently and reliably is a shared aspiration, yet the journey is frequently fraught with hurdles. Imagine a world where every component, every process, and every piece of information related to your product is not just tracked, but actively contributes to its success throughout its entire existence. This isn’t just a fantasy; it’s the promise of effective Product Lifecycle Management (PLM), powerfully enhanced by an Enterprise Resource Planning (ERP) system tailored for small manufacturers.

This comprehensive guide will delve deep into how ERP for small manufacturers is not merely a software solution, but a strategic imperative that transforms how products are managed from their inception to their eventual end-of-life. We’ll explore how integrating ERP into your operations can provide the visibility, control, and efficiency needed to significantly improve your Product Lifecycle Management, ultimately driving growth, enhancing quality, and securing your competitive edge in the market.

The Unseen Challenges of Small Manufacturers in a Competitive Landscape

Running a small manufacturing business is a delicate balancing act. You’re constantly juggling design iterations, procurement, production schedules, quality control, and customer expectations, all often with limited resources and tight margins. Many small manufacturers begin their journey relying on a patchwork of spreadsheets, disparate software tools, and even paper-based records to manage these complex processes. While this approach might work in the very early stages, it quickly becomes a bottleneck as the business grows, leading to inefficiencies that can cripple progress.

The lack of a unified system creates significant “data silos,” where crucial information is locked away in different departments, making it nearly impossible to gain a holistic view of operations. This fragmentation leads to communication breakdowns, errors, delays in product development, and an inability to accurately track costs or forecast demand. In an era where agility and responsiveness are paramount, these challenges prevent small manufacturers from effectively competing with larger, more technologically advanced counterparts. The ability to manage a product’s entire lifecycle, from design to eventual retirement, becomes an elusive goal rather than a core competency.

Understanding Product Lifecycle Management (PLM) for SMEs

Product Lifecycle Management (PLM) might sound like a concept reserved for multinational corporations, but its principles are incredibly relevant, and arguably even more critical, for small and medium-sized enterprises (SMEs). At its core, PLM is a strategic approach to managing the entire life of a product from its initial conception, through design, engineering, manufacturing, service, and disposal. It’s about optimizing all the processes involved in bringing a product to market and sustaining it over time, ensuring data integrity, collaboration, and efficiency every step of the way.

For a small manufacturer, understanding PLM means recognizing the journey your product takes – from that initial sketch on a napkin, through CAD drawings, Bill of Materials creation, prototyping, rigorous testing, full-scale production, distribution, after-sales support, and finally, deciding its end-of-life strategy. Without a clear framework, each of these stages can become a disconnected, error-prone endeavor. Effective PLM helps small businesses reduce time-to-market, improve product quality, lower development costs, and make better-informed decisions based on a complete product history. It’s about more than just managing data; it’s about managing innovation and ensuring consistent quality.

The Critical Need for ERP in Small Manufacturing Operations

Many small manufacturers often hesitate to invest in an Enterprise Resource Planning (ERP) system, viewing it as an expensive, complex solution meant only for large corporations. However, this perception overlooks the profound benefits that a well-implemented ERP for small manufacturers can deliver, especially in today’s fast-paced, data-driven environment. The reality is that small businesses face many of the same operational complexities as their larger counterparts, but often with fewer resources to manage them. Manual processes, reliance on outdated software, and disconnected systems inevitably lead to inefficiency, costly errors, and lost opportunities.

Without an integrated ERP system, small manufacturers struggle with everything from inaccurate inventory counts and missed production deadlines to inefficient resource allocation and a lack of real-time visibility into their shop floor. These issues directly impact profitability and competitiveness. An ERP system centralizes data from across the business – including finance, sales, purchasing, inventory, production, and quality – providing a single source of truth. This integration is not just a convenience; it’s a fundamental shift that empowers small manufacturers to make data-driven decisions, optimize workflows, and react swiftly to market changes, laying the groundwork for improved Product Lifecycle Management from the very start.

Bridging the Gap: How ERP Integrates with PLM Principles

While PLM focuses specifically on the product’s journey and associated data, and ERP handles the operational execution of the business, these two concepts are not mutually exclusive; they are profoundly complementary. In fact, an effective ERP for small manufacturers acts as the crucial backbone that brings PLM principles to life within a business. Think of PLM as the strategic roadmap for your product, defining what needs to happen and why, while ERP provides the operational engine that executes those plans, managing the “how.”

ERP systems streamline the flow of information that is vital for PLM. For instance, engineering data from CAD systems, often managed by PLM tools or even manually, can be seamlessly integrated into the ERP’s Bill of Materials (BOM) module. This ensures that the design intent is accurately translated into manufacturing requirements, preventing discrepancies and errors that often arise when data is manually re-entered across different systems. By providing a unified platform for managing resources, production schedules, inventory, and finances, ERP ensures that every stage of the product lifecycle, from initial design costing to end-of-life inventory management, is supported by real-time, accurate data. This integration is key to achieving a truly cohesive and efficient Product Lifecycle Management strategy.

Streamlining Design and Engineering Processes with ERP-Enabled Data

The initial stages of Product Lifecycle Management—design and engineering—are foundational to a product’s success. However, for many small manufacturers, these stages can be disconnected from the realities of production, leading to costly redesigns and delays. This is where an ERP for small manufacturers truly shines, by bringing manufacturing insights directly into the engineering workflow, even if a dedicated PLM system isn’t yet in place. The ERP system becomes the central repository for critical product data, ensuring that engineering decisions are informed by production capabilities and material availability.

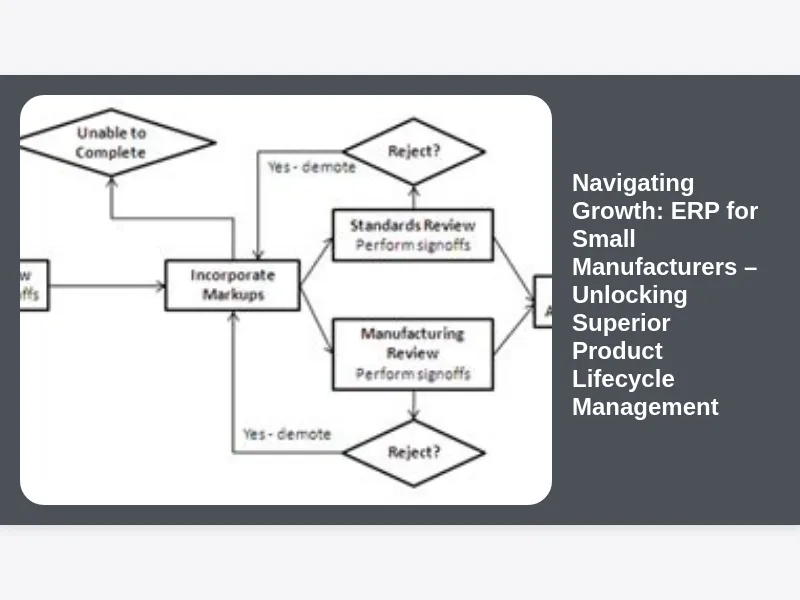

Central to this is the management of Bills of Materials (BOMs) and routings within the ERP. Engineers can use the ERP to define the precise list of components, raw materials, and sub-assemblies required for a product, along with the detailed sequence of operations needed to manufacture it. This capability ensures accuracy and consistency, preventing errors that can propagate throughout the production process. Furthermore, ERP facilitates robust version control and the management of engineering changes (ECOs). When a design modification occurs, the ERP system can track the change, its impact on materials and processes, and ensure all relevant departments are updated, minimizing the risk of building outdated versions of a product. This seamless transition from engineering design to production readiness is a cornerstone of effective Product Lifecycle Management.

Enhanced Production Planning and Scheduling for Small Manufacturers

For small manufacturers, inefficient production planning and scheduling can lead to significant bottlenecks, missed deadlines, and underutilized resources. This is precisely where a robust ERP for small manufacturers delivers substantial improvements, fundamentally transforming the operational core of the business. By centralizing all relevant data—including customer orders, inventory levels, machine capacities, and labor availability—ERP systems provide the intelligence needed to create highly optimized production schedules. This is a critical component of effective Product Lifecycle Management, ensuring products move through the manufacturing phase as efficiently as possible.

The Material Requirements Planning (MRP) functionality within an ERP system is particularly powerful. It automatically calculates the exact quantities of raw materials and components needed, and when they are required, based on the production schedule and current inventory. This eliminates guesswork, reduces the risk of stockouts, and prevents overstocking, which ties up valuable capital. Furthermore, ERP enables sophisticated capacity planning, allowing manufacturers to allocate resources—machines, tools, and personnel—optimally, ensuring that production lines are not overloaded or left idle. The result is a smoother, more predictable production flow, reduced lead times, and a significant improvement in on-time delivery rates, directly benefiting the product’s journey through its lifecycle.

Mastering Inventory and Supply Chain for PLM Success

Managing inventory and the supply chain effectively is paramount for any manufacturer, but for small businesses, the stakes are often higher due to tighter cash flow and limited storage space. An integrated ERP for small manufacturers is an indispensable tool for mastering these critical areas, directly impacting the success of Product Lifecycle Management by ensuring that the right materials are available at the right time, and at the right cost. Disjointed inventory management leads to production delays, increased carrying costs, and customer dissatisfaction; an ERP system provides the necessary antidote.

The ERP system offers real-time visibility into inventory levels across all locations, from raw materials to work-in-progress and finished goods. This means manufacturers can accurately track what they have, what’s on order, and what’s committed to production, making informed decisions about purchasing and production planning. Beyond internal inventory, ERP extends its reach into the supply chain by facilitating better supplier management. It helps track supplier performance, manage purchase orders, and streamline communication, ensuring that inbound materials meet quality standards and arrive on schedule. By optimizing the entire material flow, from supplier to customer, ERP minimizes waste, reduces lead times, and significantly contributes to the smooth progression of products through their lifecycle, bolstering overall PLM success.

Ensuring Quality Control and Compliance Throughout the Lifecycle

Quality is non-negotiable in manufacturing, regardless of size. For small manufacturers, maintaining consistent quality and adhering to regulatory compliance standards can be challenging without proper systems in place. This is where ERP for small manufacturers extends its value beyond just production and inventory, offering robust capabilities for integrating quality control and compliance management throughout the entire Product Lifecycle Management process. Ensuring product integrity from design to delivery and beyond is crucial for reputation and customer loyalty.

An ERP system can be configured to capture and track crucial quality data at various stages of production, from incoming material inspection to in-process checks and final product testing. This allows manufacturers to identify trends, pinpoint the root causes of defects, and implement corrective actions swiftly. When non-conformances occur, the ERP can manage the entire process, from documenting the issue to initiating returns, rework, or scrap, ensuring full traceability. Furthermore, for industries with stringent regulatory requirements, ERP systems can help enforce standard operating procedures, track certifications, and generate audit trails, proving compliance. By embedding quality checks and compliance protocols directly into the operational workflow, ERP helps small manufacturers produce superior products consistently, reducing costly recalls and safeguarding their brand.

Boosting Customer Satisfaction and After-Sales Service

The product lifecycle doesn’t end when an item leaves the factory floor; its journey continues through customer use and after-sales service. For small manufacturers, delivering exceptional customer experience and efficient post-sale support is a powerful differentiator. An effective ERP for small manufacturers plays a crucial role in enhancing customer satisfaction and streamlining after-sales service, thereby completing the full circle of Product Lifecycle Management. By connecting product data with customer interactions, ERP fosters a more responsive and informed service approach.

Through the ERP system, manufacturers can maintain a comprehensive history of each product sold, including its serial number, manufacturing date, warranty information, and any past service records. This information is invaluable for providing quick and accurate support when customers encounter issues or require spare parts. The system can help manage warranty claims, track repairs, and even facilitate product returns and replacements efficiently. Moreover, by integrating customer feedback and service data back into the product development cycle, ERP enables small manufacturers to identify common issues, implement product improvements, and develop new offerings that better meet market needs. This continuous feedback loop closes the PLM circle, ensuring that lessons learned from the field directly inform future product iterations, ultimately driving loyalty and repeat business.

Data-Driven Decision Making: The Analytical Power of ERP for PLM

In today’s competitive manufacturing environment, relying on intuition or fragmented data is a recipe for stagnation. For small manufacturers to thrive and genuinely excel at Product Lifecycle Management, they need the ability to make informed, data-driven decisions at every turn. This is precisely where the analytical power of ERP for small manufacturers becomes indispensable. By consolidating vast amounts of operational data into a single, accessible platform, ERP transforms raw information into actionable insights that can propel a business forward.

An ERP system offers robust reporting and analytics capabilities that provide a holistic view of manufacturing operations. Manufacturers can generate reports on production efficiency, inventory turnover, cost analysis, sales performance, and profitability for specific product lines or individual items. Imagine being able to quickly assess which products are most profitable, identify bottlenecks in your production process, or understand the true cost of a design change. These insights enable small manufacturers to continuously optimize their operations, refine product designs, and make strategic decisions about resource allocation and market positioning. By providing a clear, accurate picture of their business performance, ERP empowers small manufacturers to move beyond reactive problem-solving and embrace proactive, strategic planning, significantly enhancing their overall Product Lifecycle Management effectiveness.

Addressing Common Misconceptions: Is ERP Too Complex for Small Manufacturers?

One of the most pervasive myths preventing small manufacturers from embracing an ERP system is the belief that it is inherently too complex, too expensive, or simply overkill for their operations. Many imagine unwieldy, legacy systems requiring massive IT teams and multi-year implementation projects. However, this perception largely stems from outdated notions and fails to acknowledge the significant advancements in ERP for small manufacturers in recent years. The landscape has evolved dramatically, offering solutions specifically designed to meet the unique needs and budgets of smaller businesses.

Today’s ERP solutions for SMEs are often cloud-based, meaning they require minimal upfront IT infrastructure investment and can be accessed from anywhere, offering unprecedented flexibility. These systems are typically more modular, allowing small manufacturers to implement only the functionalities they need initially and scale up as they grow. User interfaces have become far more intuitive, reducing the learning curve for employees. Furthermore, the total cost of ownership has decreased significantly, with subscription-based models making enterprise-level functionality accessible. The idea that ERP is too complex is a misconception that, if left unaddressed, can hold small manufacturers back from achieving the integrated operations and superior Product Lifecycle Management capabilities that their businesses truly need to compete and flourish.

Choosing the Right ERP System: Key Considerations for Small Manufacturing Businesses

Selecting the ideal ERP for small manufacturers is a critical decision that can profoundly impact a business’s operational efficiency and its ability to manage Product Lifecycle Management effectively. It’s not a one-size-fits-all solution, and a careful evaluation process is essential to ensure the chosen system aligns perfectly with the unique needs and growth aspirations of the company. Hasty decisions or opting for the cheapest solution without due diligence can lead to costly rework and buyer’s remorse down the line.

Firstly, consider industry-specific features. Does the ERP solution have modules and functionalities specifically designed for manufacturing, such as robust BOM management, shop floor control, and MRP? A generic ERP might not offer the depth required for complex production processes. Secondly, evaluate scalability and integration capabilities. Can the system grow with your business, and can it integrate with existing tools like CAD software, CRM, or accounting packages? User-friendliness is also paramount; an intuitive interface will drive user adoption and reduce training time. Finally, don’t overlook vendor support and implementation services. A reliable vendor that offers strong training, ongoing support, and proven implementation methodologies is invaluable for a smooth transition. Taking the time to research, compare, and pilot potential solutions will pay dividends in achieving enhanced Product Lifecycle Management and overall business success. [Link to Trusted Source e.g., Software Advice Guide to ERP Selection]

The Implementation Journey: A Roadmap for Small Manufacturers

Embarking on the ERP implementation journey can seem daunting for small manufacturers, but with a clear roadmap and a methodical approach, it becomes a manageable and ultimately rewarding process. The successful integration of ERP for small manufacturers is less about the software itself and more about careful planning, effective execution, and strategic change management. Viewing it as a business transformation project, rather than just an IT installation, is crucial for realizing its full potential in enhancing Product Lifecycle Management.

The journey typically begins with a thorough planning phase, where a dedicated project team defines clear objectives, scopes the project, and identifies key performance indicators (KPIs). Data migration is a critical step; ensuring clean, accurate data from legacy systems is transferred correctly into the new ERP is paramount. This often involves significant data cleansing beforehand. Next comes system configuration and customization, tailoring the ERP to specific business processes without over-customizing, which can complicate future upgrades. User training is another vital component; employees need to understand not just how to use the new system, but also how their roles change and the benefits it brings. Finally, a phased rollout, often starting with a pilot department, can help identify and resolve issues before a full company-wide launch. A well-managed implementation minimizes disruption and maximizes the speed at which your business can leverage the ERP for superior Product Lifecycle Management.

Financial Benefits: ROI of ERP for Small Manufacturers

Investing in an ERP for small manufacturers is a significant financial commitment, but it’s one that typically delivers a substantial return on investment (ROI) by driving efficiencies, reducing costs, and enabling growth. While the upfront costs might seem high, the long-term benefits far outweigh them, making ERP a strategic financial decision for businesses aiming for improved Product Lifecycle Management and sustained profitability. The key is to look beyond immediate expenditures and consider the comprehensive impact on the bottom line.

One of the most direct financial benefits comes from cost savings in operations. By streamlining processes, reducing manual errors, and automating tasks, ERP minimizes labor costs and improves overall productivity. Enhanced inventory management, for instance, leads to lower carrying costs, reduced waste from obsolescence, and fewer stockouts that can halt production. Furthermore, ERP contributes to increased revenue through faster time-to-market for new products, improved order fulfillment rates, and better customer satisfaction that encourages repeat business. The ability to make data-driven decisions based on real-time financial and operational insights also leads to better budgeting, more accurate forecasting, and ultimately, greater profitability. For small manufacturers, ERP is not just an expense; it’s an investment in efficiency, accuracy, and competitive advantage, all of which directly contribute to a stronger financial position and optimized Product Lifecycle Management.

Beyond the Basics: Advanced Features Supporting Product Lifecycle Management

While core ERP functionalities offer substantial improvements, modern ERP for small manufacturers is continuously evolving, incorporating advanced features that can take Product Lifecycle Management to an entirely new level. These cutting-edge capabilities empower small businesses to not only keep pace with larger competitors but also to innovate and future-proof their operations. Exploring these advanced options allows manufacturers to extend the reach and impact of their ERP system.

Consider the integration of Internet of Things (IoT) devices. ERP systems can now collect real-time data directly from machinery on the shop floor, providing unprecedented visibility into production performance, predictive maintenance needs, and quality control. This data can inform better design decisions and optimize manufacturing processes within the PLM framework. Advanced analytics and business intelligence (BI) tools built into or integrated with ERP can uncover deeper insights, identifying subtle trends in product performance, customer feedback, and market demand that might otherwise go unnoticed. Furthermore, some ERP systems are beginning to incorporate elements of Artificial Intelligence (AI) and Machine Learning (ML) for enhanced forecasting, automated quality checks, and even optimizing supply chain routes. While not all small manufacturers will immediately require these features, understanding their potential ensures that the chosen ERP solution can support a long-term vision for advanced Product Lifecycle Management and digital transformation.

Overcoming Challenges: Common Pitfalls and How to Avoid Them

Even with the clearest roadmap, implementing ERP for small manufacturers isn’t without its potential challenges. Acknowledging these common pitfalls upfront and developing strategies to circumvent them is crucial for a successful transition and achieving the desired improvements in Product Lifecycle Management. Many setbacks can be avoided with proactive planning and effective communication.

One of the most common issues is a lack of stakeholder buy-in. If employees and management don’t understand the “why” behind the ERP implementation, resistance to change can derail the project. This can be mitigated through transparent communication, involving key users in the selection process, and highlighting the personal and business benefits. Another pitfall is poor planning, especially regarding data migration and customization. Rushing these stages or failing to properly cleanse data can lead to errors that plague the system for years. Over-customization is also a trap; while tailoring is necessary, excessive modifications can make future upgrades difficult and costly. Insufficient training is another significant hurdle; users must feel confident and competent with the new system. Finally, beware of scope creep, where additional features are continually added throughout the project, extending timelines and budgets. By focusing on a well-defined scope, robust planning, and strong change management, small manufacturers can successfully navigate these challenges and unlock the full potential of their ERP for enhanced Product Lifecycle Management.

The Future of Manufacturing: ERP as a Catalyst for Digital Transformation

The manufacturing world is undergoing a profound shift, often referred to as Industry 4.0, characterized by automation, data exchange, and advanced connectivity. For small manufacturers, simply maintaining the status quo is no longer an option for long-term survival and growth. Embracing ERP for small manufacturers is not just about optimizing current operations; it’s about positioning the business as a catalyst for digital transformation, ensuring it remains competitive and agile in this evolving landscape. ERP becomes the foundational technology upon which future innovations are built.

An ERP system serves as the central nervous system for a digitally transformed factory. It enables the seamless flow of data between various operational technologies (OT) and information technologies (IT), facilitating real-time decision-making and automated processes. By connecting design, production, supply chain, and customer interactions, ERP provides the unified platform necessary to explore advanced concepts like predictive analytics, machine learning for quality control, and even aspects of digital twin technology. It empowers small manufacturers to move away from reactive problem-solving towards proactive, intelligent manufacturing. Without a robust ERP, leveraging these future technologies effectively and achieving truly integrated Product Lifecycle Management becomes significantly more challenging. Thus, investing in ERP is not just an operational decision; it’s a strategic move towards a more connected, efficient, and future-ready manufacturing enterprise.

Case Studies (Simulated): Real-World Impact on Small Manufacturers

Let’s consider two hypothetical scenarios illustrating the tangible impact of ERP for small manufacturers on Product Lifecycle Management:

Case Study 1: “Precision Gears Inc.” – From Chaos to Clarity

Precision Gears Inc., a small manufacturer of custom industrial gears, struggled with a fragmented system. Design specifications were in CAD files, inventory in spreadsheets, and production schedules on a whiteboard. When a critical component was updated, it often took days to ensure all departments had the correct revision, leading to costly rework. Implementing an ERP system with strong BOM and engineering change management modules revolutionized their process. Now, a design change triggers an automated workflow, updating all relevant production orders, inventory records, and supplier communications within hours. This integration reduced their engineering change error rate by 70% and cut product development lead times by 25%, significantly improving their Product Lifecycle Management efficiency. Their on-time delivery rate soared, leading to increased customer trust and new contracts.

Case Study 2: “Eco-Friendly Furniture Co.” – Enhanced Sustainability and Traceability

Eco-Friendly Furniture Co. prided itself on sustainable practices but found tracking material origins, waste streams, and product disposal guidelines challenging. Their manual processes for quality checks and regulatory reporting were cumbersome. After implementing an ERP for small manufacturers focused on end-to-end traceability and quality control, they gained unprecedented insight. The ERP now tracks every raw material batch from certified suppliers, linking it directly to finished products. If a defect is found, they can instantly trace affected products and batches. Furthermore, the system helps them monitor waste generation at each production stage, enabling targeted reduction efforts, a critical aspect of their sustainability-focused Product Lifecycle Management. This not only improved compliance but also bolstered their brand image, attracting a new segment of environmentally conscious consumers and proving the value of a comprehensive PLM approach.

Conclusion: Embracing ERP for Sustainable Growth and PLM Excellence in Small Manufacturing

The journey of a product, from its initial spark of an idea to its eventual retirement, is complex and multifaceted. For small manufacturers navigating competitive markets, optimizing this Product Lifecycle Management (PLM) is not merely an advantage; it’s a necessity for sustainable growth. As we’ve explored, the most powerful catalyst for achieving superior PLM lies in the intelligent implementation of ERP for small manufacturers. It’s the central nervous system that connects disparate functions, harmonizes data, and provides the visibility and control essential for modern manufacturing.

By investing in an ERP system, small manufacturers can move beyond the limitations of manual processes and disconnected systems. They can streamline design-to-production workflows, enhance production planning, master inventory and supply chain dynamics, ensure unwavering quality and compliance, and ultimately deliver exceptional customer experiences. The financial benefits are clear, and the strategic advantages in a rapidly digitizing world are undeniable. While the path to implementation requires commitment and careful planning, the rewards of increased efficiency, reduced costs, accelerated innovation, and data-driven decision-making are transformative. Embracing a tailored ERP solution is not just about adopting new software; it’s about making a strategic investment in the future, securing a stronger competitive position, and empowering your small manufacturing business to achieve excellence across every stage of the product lifecycle.