In today’s dynamic industrial landscape, small batch manufacturing stands as a testament to specialized craftsmanship, unique product offerings, and a deep connection to customer needs. Yet, the very characteristics that make it unique – high product variety, customization, and often lower volumes – also present formidable operational challenges. Traditional manufacturing systems, often rigid and siloed, struggle to keep pace with the agility required for rapid changeovers, fluctuating demand, and intricate supply chains inherent in small batch production. This is where the power of a seamlessly integrated Cloud ERP system emerges as a transformative solution, offering small batch manufacturers the tools to not only survive but thrive in a competitive marketplace.

This comprehensive guide delves into how the strategic adoption and seamless integration of Cloud ERP for small batch manufacturing can revolutionize operations, from initial order to final delivery. We’ll explore the unique pain points of this sector and demonstrate how a unified cloud-based enterprise resource planning solution addresses them head-on, fostering efficiency, improving decision-making, and ultimately driving profitability. Prepare to discover how embracing this digital evolution can empower your small batch business to achieve unprecedented levels of operational excellence and responsiveness.

The Unique Landscape of Small Batch Manufacturing: Why Traditional Systems Fall Short

Small batch manufacturing is fundamentally different from its mass-production counterpart. It’s characterized by producing a limited quantity of goods, often highly customized or specialized, with frequent changes in product lines or specifications. Think bespoke furniture, specialized electronic components, craft beverages, or custom machinery parts. These businesses thrive on flexibility, innovation, and a close relationship with their customers.

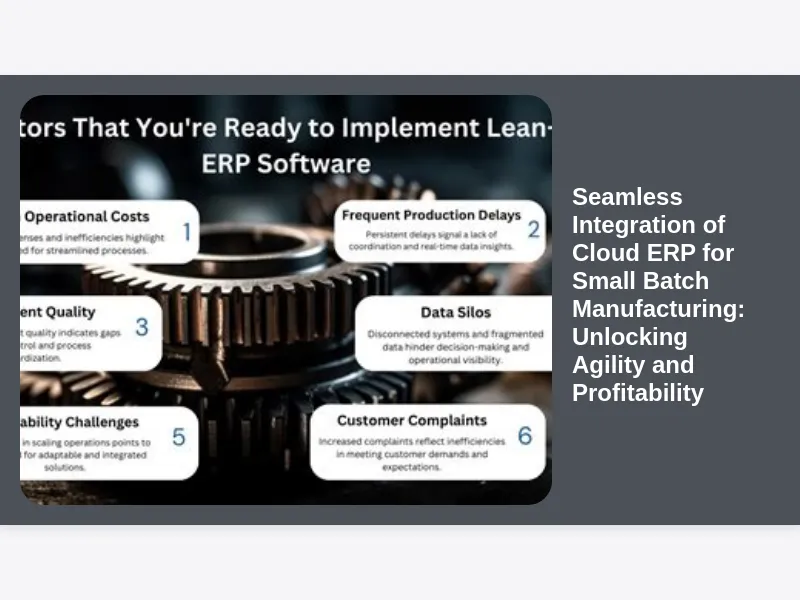

However, this agility comes with inherent complexities. Manufacturers in this sector frequently contend with intricate production schedules, managing a vast array of raw materials for diverse products, navigating rapid demand shifts, and ensuring consistent quality across variations. Many small batch operations still rely on a patchwork of disparate systems – spreadsheets for inventory, separate software for accounting, manual whiteboards for production scheduling – or even paper-based processes. This fragmented approach inevitably leads to data silos, manual data entry errors, delayed information flow, and a pervasive lack of real-time visibility. When systems don’t “talk” to each other, the small batch manufacturer is left guessing, reacting rather than anticipating, and ultimately losing precious time and money. This highlights the critical need for a holistic, integrated solution that can consolidate all these moving parts into a single, cohesive operational framework.

Understanding Cloud ERP: A Foundation for Modern Agility

Before diving into the specifics of seamless integration, it’s crucial to understand what Cloud ERP entails. ERP, or Enterprise Resource Planning, is a comprehensive software system designed to manage and integrate all the core processes of a business, from finance and human resources to supply chain management, manufacturing, and customer service. In a traditional sense, ERP systems were often deployed “on-premise,” meaning the software and its data resided on servers within the company’s own facilities.

Cloud ERP, on the other hand, operates as a Software-as-a-Service (SaaS) model. The software and data are hosted on a vendor’s remote servers and accessed by users over the internet, typically through a web browser. This fundamental shift in deployment brings a host of advantages, particularly for small to medium-sized businesses (SMBs) in the small batch sector. These include significantly lower upfront IT infrastructure costs, automatic software updates and maintenance managed by the vendor, enhanced data security, and the ability for employees to access the system from anywhere, at any time, on any device. Cloud ERP provides the technological backbone for modern business agility, freeing small batch manufacturers from the burden of complex IT management and allowing them to focus on what they do best: creating exceptional products.

Why Integration Matters: Bridging Gaps in Small Batch Production Workflows

The concept of “integration” is the cornerstone of any effective ERP system, and it’s especially vital for the multifaceted world of small batch manufacturing. Integration, in this context, refers to the ability of different software modules and business processes to communicate and share data seamlessly with each other. Imagine a scenario where a new customer order comes in. Without integration, sales might use one system, production planning another, inventory a third, and finance a fourth. Each department would be manually transferring information, leading to delays, transcription errors, and conflicting data.

The problems caused by a lack of integration are profound for small batch operations. Data silos prevent a holistic view of the business, making it impossible to accurately track costs, monitor production progress, or forecast demand. Manual data entry becomes a bottleneck, consuming valuable time and introducing errors that ripple through the entire organization. Delayed decision-making becomes the norm, as managers lack real-time insights into inventory levels, production capacity, or customer status. Seamless integration of Cloud ERP directly addresses these issues by establishing a single source of truth for all business data. It ensures that information flows effortlessly between sales, planning, production, inventory, and finance, creating a unified operational ecosystem where every department operates with the most current and accurate data, transforming reactive businesses into proactive, data-driven entities.

Real-Time Visibility and Data-Driven Decisions with Integrated Cloud ERP

One of the most profound advantages offered by the seamless integration of Cloud ERP for small batch manufacturing is the unprecedented level of real-time visibility it provides across the entire operation. Gone are the days of waiting for end-of-day reports or manually compiling data from various spreadsheets. With an integrated system, every transaction, every production step, every inventory movement is recorded instantly and reflected across all relevant modules. This means that a sales representative can check current stock levels and production lead times while talking to a customer, a production manager can see real-time progress on multiple orders, and a finance team can instantly access updated costings and revenue figures.

This “single source of truth” eliminates ambiguity and empowers stakeholders with the accurate, up-to-the-minute information needed to make truly data-driven decisions. For small batch manufacturers, this translates into a powerful competitive edge. They can react quickly to changes in customer demand, proactively address potential supply chain disruptions, optimize production schedules on the fly, and identify bottlenecks before they cause significant delays. The ability to see the complete picture, from raw material arrival to finished product shipment, drastically improves responsiveness, reduces waste, and allows for agile adjustments that are critical in the high-mix, low-volume environment.

Optimizing Production Planning and Scheduling for High-Mix, Low-Volume Operations

Production planning and scheduling are arguably the most intricate challenges for small batch manufacturers. Unlike mass production, where processes are highly repetitive, small batch operations contend with frequent changeovers, varying material requirements for each product variation, and the constant balancing act between setup times and throughput. Manual or disconnected planning systems often lead to inefficient use of resources, missed deadlines, and suboptimal production sequences.

An integrated Cloud ERP system, specifically tailored for small batch manufacturing, brings sophisticated capabilities to this crucial area. Its production module, when connected to sales orders, inventory, and capacity planning, can intelligently generate master production schedules (MPS) that account for unique order requirements, material availability, and machine capacities. Advanced Material Requirements Planning (MRP) ensures that the right components are available precisely when needed, minimizing both holding costs and production delays. Furthermore, the system can help optimize sequences to reduce setup times, group similar jobs, and visualize bottlenecks, allowing for proactive adjustments. This level of integrated planning transforms what was once a chaotic process into a highly optimized, efficient workflow, ensuring that small batch manufacturers can deliver on their promises of customization and quality, on time.

Enhanced Inventory Management and Supply Chain Synchronization

For small batch manufacturers, inventory is a double-edged sword. Too much raw material or work-in-progress (WIP) ties up capital and risks obsolescence, especially with highly specialized components. Too little, and production grinds to a halt, leading to missed deadlines and dissatisfied customers. Managing this delicate balance across a diverse product portfolio is incredibly complex without a unified system.

Seamless integration of Cloud ERP for small batch manufacturing provides robust tools for enhanced inventory management and supply chain synchronization. By linking sales forecasts, production schedules, and purchase orders, the ERP system can accurately predict material needs and trigger timely replenishment. It tracks raw materials, components, WIP, and finished goods across multiple locations, providing real-time stock levels and valuation. Beyond internal inventory, a truly integrated system can extend its reach to the supply chain. Through supplier portals or Electronic Data Interchange (EDI), it can facilitate real-time communication with vendors, provide visibility into inbound shipments, and even support Just-In-Time (JIT) strategies where feasible. This synchronized approach minimizes stockouts, reduces excess inventory, improves supplier relationships, and ensures that the right materials are always available at the right time, directly impacting the bottom line.

Streamlining Financial Operations and Cost Control in Manufacturing

Understanding true costs is paramount for profitability in small batch manufacturing, where each unique product or custom order can have varying material, labor, and overhead expenses. Disconnected financial systems often make accurate job costing, profitability analysis, and even basic accounting reconciliation a monumental task. Errors in costing can lead to underpricing, eroding margins, or overpricing, making products uncompetitive.

A seamlessly integrated Cloud ERP for small batch manufacturing centralizes all financial operations, linking them directly to manufacturing activities. General ledger, accounts payable, accounts receivable, payroll, and fixed asset management are all housed within the same system. Crucially, the ERP’s manufacturing module feeds real-time production data – material consumption, labor hours, machine usage – directly into the financial module. This enables highly accurate job costing, activity-based costing, and sophisticated profitability analysis at the product or order level. With clear visibility into expenditures and revenues, small batch manufacturers can better control costs, identify areas of waste, optimize pricing strategies, and ensure compliance with financial regulations. The result is improved cash flow, greater financial transparency, and a solid foundation for sustainable growth.

Elevating Quality Control and Regulatory Compliance with Integrated Systems

In small batch manufacturing, where reputation often hinges on the quality and precision of bespoke products, maintaining stringent quality control standards is non-negotiable. Furthermore, many specialized industries are subject to strict regulatory compliance, requiring meticulous record-keeping and adherence to specific processes. Manual quality checks and disjointed documentation can introduce inconsistencies, make audits challenging, and potentially lead to costly recalls or penalties.

An integrated Cloud ERP system provides a robust framework for elevating quality control and streamlining regulatory compliance. The ERP’s quality management module, seamlessly connected to production and inventory, can track quality checks at various stages of the manufacturing process, from incoming raw materials to final assembly. It facilitates the recording of non-conformances, triggers corrective and preventive actions (CAPA), and manages quality documentation centrally. For compliance, the system offers complete audit trails, documenting every change, every approval, and every process step. This ensures traceability from raw material lot numbers through every production stage to the finished product, which is invaluable for industries like medical devices, aerospace, or specialized food production. By embedding quality and compliance into the core operational workflow, small batch manufacturers can uphold their reputation, meet regulatory demands, and build enduring customer trust.

Connecting the Dots: CRM, Sales, and Customer Satisfaction

In the small batch world, customer relationships are often deeply personal and critical for repeat business and referrals. Customers expect tailored products, transparent communication, and efficient service. However, when sales, order fulfillment, and customer service operate in isolation, vital customer information can get lost, leading to miscommunications, delayed responses, and ultimately, dissatisfied clients.

The seamless integration of Cloud ERP for small batch manufacturing extends its benefits beyond the factory floor to directly impact customer satisfaction. By integrating Customer Relationship Management (CRM) functionalities within the ERP, or linking a dedicated CRM to the core system, all customer interactions are centralized. Sales teams have immediate access to customer order history, product specifications, and payment terms. When a new order is placed, it flows directly into production planning and inventory, providing real-time status updates that can be shared with the customer. Service requests can be logged and tracked, ensuring timely resolution. This holistic view of the customer journey enables personalized engagement, accurate order fulfillment, and proactive communication, reinforcing the value proposition of customized products and fostering enduring customer loyalty – a key differentiator for any small batch business.

The Path to Implementation: Navigating Your Cloud ERP Journey

Embarking on a Cloud ERP implementation is a significant undertaking, but for small batch manufacturers, it’s a journey towards greater efficiency and competitiveness. The first crucial step is a thorough needs assessment. What are your current pain points? Which processes are most inefficient? What specific features are critical for your unique production environment? This will guide your vendor selection process. Look for vendors with experience in manufacturing, and ideally, small batch or high-mix, low-volume production, as their solutions will be more attuned to your specific requirements. Don’t be swayed by generic offerings; seek out solutions that demonstrate flexibility and configurability.

A phased approach to implementation often proves most effective, especially for SMBs. Instead of trying to implement everything at once, focus on critical modules first, such as finance and inventory, then gradually expand to production, quality, and CRM. Change management is another vital component. Any new system will encounter resistance, so investing in comprehensive user training and clearly communicating the benefits of the new system to your team is paramount. A dedicated internal project team, supported by the chosen ERP vendor, will ensure a smoother transition and maximize the chances of a successful seamless integration of Cloud ERP for small batch manufacturing. Remember, this isn’t just a software installation; it’s a strategic business transformation.

Overcoming Common Integration Hurdles: Strategies for Success

While the promise of seamless integration of Cloud ERP for small batch manufacturing is compelling, the path to achieving it isn’t always without its challenges. Understanding and preparing for common hurdles is crucial for a successful implementation. Data migration, for instance, can be complex, especially if you’re moving from a multitude of disparate legacy systems or spreadsheets. Ensuring data cleanliness, accuracy, and proper mapping to the new ERP structure requires meticulous planning and execution. System compatibility, particularly when integrating with highly specialized existing machinery or niche software, can also pose difficulties. It’s essential to thoroughly vet integration capabilities during the vendor selection phase.

Customization needs can also be a double-edged sword; while flexibility is good, over-customizing can complicate updates and increase costs. Strive for configuration over customization wherever possible. Finally, resistance to change within the organization is a human element that cannot be overlooked. To overcome these hurdles, adopt several best practices: maintain a clear and realistic scope for the project, dedicate a strong internal team to lead the charge, conduct rigorous testing of all integrated workflows before going live, and ensure you have strong ongoing support from your chosen ERP vendor. Proactive communication and robust training will pave the way for a truly seamless integration of Cloud ERP.

Scalability and Future-Proofing Your Small Batch Manufacturing Business

The dynamic nature of small batch manufacturing often means businesses need to be ready for growth, product diversification, or shifts in market demand. A rigid, on-premise system can quickly become a bottleneck, requiring significant investment in new hardware or software licenses to scale up. This inflexibility can stifle growth and limit a manufacturer’s ability to adapt.

This is where the inherent scalability of Cloud ERP shines, offering a vital advantage for small batch manufacturing. Cloud-based solutions are designed to scale effortlessly. As your business grows, you can typically add more users, new modules, or expand storage capacity with relative ease, often with just a few clicks or a conversation with your vendor. This pay-as-you-grow model means you only pay for the resources you use, avoiding the upfront capital expenditure of an on-premise system. Furthermore, cloud vendors continuously update and enhance their platforms, incorporating new technologies like AI, machine learning, and IoT. This means your ERP system is constantly evolving and improving, without you needing to manage complex upgrades. By adopting a seamlessly integrated Cloud ERP, small batch manufacturers effectively future-proof their operations, ensuring they have the technological foundation to adapt, innovate, and thrive well into the future, irrespective of market shifts or business expansion.

Data Analytics and Business Intelligence: Turning Information into Actionable Insights

Having a wealth of integrated data is one thing; leveraging it to gain actionable insights is another. For small batch manufacturers, where decisions must be precise and agile, the ability to analyze performance trends and identify opportunities or potential issues is invaluable. Disparate systems make this nearly impossible, as data often needs to be manually extracted, reconciled, and then analyzed in separate tools.

With seamless integration of Cloud ERP for small batch manufacturing, all operational and financial data resides in a single, unified database. This makes it incredibly powerful for data analytics and business intelligence (BI). The ERP system can generate custom reports, interactive dashboards, and key performance indicator (KPI) tracking in real-time. Managers can visualize trends in sales, production efficiency, inventory turnover, customer order cycles, and profitability across different product lines or projects. This empowers them to identify bottlenecks, pinpoint inefficiencies, evaluate product profitability with accuracy, and even forecast demand more precisely. Furthermore, many modern Cloud ERPs incorporate predictive analytics capabilities, helping small batch manufacturers anticipate equipment maintenance needs or optimize production schedules based on historical data. By transforming raw information into clear, actionable insights, Cloud ERP elevates decision-making from guesswork to strategic advantage.

The ROI of Seamless Integration: Justifying Your Cloud ERP Investment

Any significant investment in technology requires a clear understanding of its return on investment (ROI). For small batch manufacturers considering the seamless integration of Cloud ERP, the benefits often extend far beyond simple cost savings, though those are significant. Quantifiable benefits include reduced operational costs through increased efficiency, minimized manual errors, and optimized inventory levels. Faster time-to-market for new products, improved production throughput, and better resource utilization directly contribute to the bottom line. Accurate costing and pricing ensure healthier profit margins. Studies by industry analysts frequently highlight significant improvements in these areas after successful ERP implementation.

Beyond the measurable figures, there are numerous intangible benefits that contribute immensely to a stronger, more resilient business. These include enhanced decision-making capabilities, leading to more strategic planning and agile responses to market changes. Improved customer satisfaction and loyalty, stemming from better communication and on-time delivery, build a valuable brand reputation. Increased employee morale, empowered by efficient tools and reduced frustration from manual tasks, fosters a more productive work environment. While these may be harder to put a dollar figure on, their long-term impact on business sustainability and growth for a small batch operation is undeniable. The investment in a well-integrated Cloud ERP is an investment in the future agility and profitability of your manufacturing business.

Choosing the Right Cloud ERP Solution for Your Small Batch Needs

The market for Cloud ERP solutions is vast, and selecting the right one for your small batch manufacturing business is a critical decision. It’s not a one-size-fits-all scenario, and a generic ERP might miss the nuances of your operations. The first step is to prioritize industry-specific features. Does the solution understand concepts like job costing, multi-level BOMs (Bill of Materials), serial number tracking, or configuration management relevant to custom products? Look for vendors with a proven track record in manufacturing, and specifically, those who demonstrate an understanding of high-mix, low-volume environments.

Vendor reputation, including their support model and commitment to ongoing development, is also paramount. You’re not just buying software; you’re entering a long-term partnership. Inquire about their implementation methodology and post-go-live support. Carefully evaluate the pricing model, understanding what’s included and what might incur additional costs. Request live demonstrations that are tailored to your specific workflows and products, and whenever possible, ask for references from similar small batch manufacturers. Don’t shy away from asking about customization options, but always balance flexibility with the desire to stay as close to standard functionality as possible to ease future upgrades. A thoughtful selection process is key to ensuring a seamless integration of Cloud ERP for small batch manufacturing that truly meets your unique business needs.

Embracing Digital Transformation: A Cultural Shift for Manufacturers

The adoption of a seamlessly integrated Cloud ERP for small batch manufacturing isn’t merely a technological upgrade; it represents a significant step in your journey of digital transformation. This broader concept encompasses a fundamental shift in how a business operates, leveraging digital technologies to improve processes, culture, and customer experiences. While ERP is the central nervous system of this transformation, its success hinges on more than just the software itself. It requires a cultural shift within the organization.

Leadership buy-in is absolutely essential. Executives must champion the ERP initiative, clearly communicate its strategic importance, and model enthusiasm for the change. Employees, from the shop floor to the front office, need to understand not just how to use the new system, but why it’s beneficial for them and the company. This involves investing in comprehensive training, fostering a culture of continuous learning, and being open to new ways of working. Empowering employees with better tools, reducing tedious manual tasks, and giving them real-time access to information can significantly boost morale and productivity. Embracing digital transformation means recognizing that technology is an enabler of people and processes, leading to a more agile, data-driven, and ultimately more competitive small batch manufacturing enterprise.

Case Studies and Success Stories: Real-World Impact for Small Batch Manufacturers

While the theoretical benefits are compelling, seeing the seamless integration of Cloud ERP for small batch manufacturing in action truly illustrates its power. Consider the example of a custom furniture maker. Prior to Cloud ERP, they struggled with tracking unique customer specifications across design, procurement, and production. Orders were delayed due to wrong materials being ordered, or components being misplaced. With an integrated Cloud ERP, customer orders now flow directly from sales to a production configurator, generating precise BOMs and routing instructions. Inventory is accurately tracked from raw lumber to finished pieces, ensuring materials are always on hand. The result? A 30% reduction in lead times, a significant decrease in material waste, and vastly improved customer satisfaction due to on-time delivery of highly customized products.

Another instance might be a specialized electronics manufacturer. They faced challenges with quality control and traceability, particularly in meeting strict industry regulations. Implementing a Cloud ERP with integrated quality management modules allowed them to track every component by serial number, record inspection points at each assembly stage, and generate comprehensive audit reports with ease. This not only ensured compliance but also significantly reduced rework and warranty claims, improving their reputation for precision and reliability. These examples, though generalized, highlight how embracing an integrated Cloud ERP solution provides tangible, transformative benefits, enabling small batch manufacturers to overcome specific operational hurdles and achieve substantial growth and efficiency gains.

Conclusion: The Future is Integrated and Cloud-Powered for Small Batch Manufacturing

The journey of seamless integration of Cloud ERP for small batch manufacturing is not merely an upgrade; it is a strategic imperative for businesses aiming for sustainable growth and competitive advantage in the modern industrial landscape. We’ve explored how Cloud ERP directly addresses the unique challenges of high-mix, low-volume production, from optimizing intricate production schedules and meticulously managing diverse inventories to streamlining financial operations and elevating quality control. The ability to connect all facets of the business – sales, production, supply chain, finance, and customer service – into a single, unified, and accessible system provides unprecedented real-time visibility and empowers data-driven decision-making.

By embracing this powerful technology, small batch manufacturers can shed the inefficiencies of disparate systems, unlock new levels of agility, enhance customer satisfaction, and significantly improve their profitability. The inherent scalability and future-proofing capabilities of cloud solutions ensure that your business remains adaptable and competitive, ready to meet the evolving demands of the market. The future of small batch manufacturing is undoubtedly integrated, intelligent, and cloud-powered. Taking the decisive step towards a seamless integration of Cloud ERP is not just an investment in software; it’s an investment in the enduring success and innovative spirit of your manufacturing enterprise.