The ambition of growth often clashes with the reality of limited resources, a perennial challenge for small manufacturing businesses. In today’s competitive landscape, Enterprise Resource Planning (ERP) systems are no longer a luxury reserved for industrial giants; they are essential tools for optimizing operations, enhancing efficiency, and driving profitability. However, for many small manufacturers, the perceived cost of implementing an ERP system remains a significant hurdle. This article delves deep into the strategies and considerations for addressing budget constraints in small manufacturing ERP projects, transforming what might seem like an insurmountable financial obstacle into a well-planned, value-driven investment.

For small manufacturing enterprises, the decision to invest in an ERP system is monumental. It represents not just a technological upgrade but a fundamental shift in how the business operates. The initial sticker price, coupled with concerns about ongoing maintenance, training, and potential implementation pitfalls, often leads to paralysis. Yet, the cost of not adopting an ERP system – inefficiency, production errors, missed opportunities, and a lack of real-time visibility – can be far greater in the long run. Our aim here is to demystify the financial aspects, providing a clear roadmap for small manufacturers to navigate the complexities of ERP procurement and implementation while staying firmly within their financial means. We will explore various models, strategies, and often overlooked opportunities to make advanced manufacturing software accessible and affordable.

Understanding the Small Manufacturer’s ERP Challenge: Why Budget is King

For small manufacturing businesses, capital is often finite and allocated with extreme prejudice. Every investment decision is scrutinized, and rightly so, as a misstep can have disproportionate consequences on cash flow and stability. When it comes to ERP, the challenge isn’t just the upfront cost of software licenses, but a complex tapestry of expenses that includes hardware, customization, implementation services, data migration, training, and ongoing support. This intricate financial web can be daunting, causing many to shy away from projects that could fundamentally transform their operational efficiency.

The common perception is that ERP systems are inherently expensive, requiring millions in investment and a team of consultants to manage. While this might have been true for large, legacy on-premise systems, the market has evolved dramatically. Today, there’s a spectrum of solutions tailored to businesses of all sizes, offering functionalities and pricing models that are far more accessible. However, without a clear understanding of these options and a strategic approach to project planning, small manufacturers can easily fall into the trap of overspending or, worse, underinvesting in a system that doesn’t meet their needs. Addressing budget constraints in small manufacturing ERP projects requires a proactive mindset, a willingness to explore alternatives, and a disciplined approach to defining scope and prioritizing needs. It’s about smart spending, not just cost-cutting.

Debunking the Myth of “Too Expensive”: Affordable ERP Solutions are Within Reach

One of the primary roadblocks for small manufacturing firms considering ERP is the pervasive myth that these systems are prohibitively expensive, a luxury only large corporations can afford. This misconception, often rooted in outdated information about traditional on-premise ERP deployments, prevents many businesses from even exploring the undeniable benefits an integrated system can offer. The reality, however, is significantly different. The ERP market has undergone a dramatic transformation over the past decade, driven by technological advancements, cloud computing, and increased competition.

Today, there are myriad affordable ERP solutions specifically designed to meet the unique needs and financial limitations of small and medium-sized enterprises (SMEs). These solutions often come with subscription-based pricing models, lower upfront costs, and scalable functionalities that allow businesses to grow into their systems without massive initial investments. Furthermore, the focus has shifted from bespoke, highly customized systems to more standardized, yet configurable, platforms that reduce implementation time and consulting fees. By addressing budget constraints in small manufacturing ERP projects through a careful evaluation of these modern offerings, small manufacturers can discover that the path to operational excellence is far more accessible than they initially imagined, offering significant ERP ROI for SMEs.

Initial Cost vs. Total Cost of Ownership (TCO): Understanding the True Investment

When evaluating an ERP system, fixating solely on the initial purchase price can be a grave mistake. While software licenses or initial subscription fees are significant, they represent only a fraction of the overall financial commitment. A more holistic and accurate approach involves calculating the Total Cost of Ownership (TCO). TCO encompasses all direct and indirect costs associated with an ERP system over its entire lifecycle, typically a five to ten-year period. This includes not just the upfront software and implementation costs, but also hardware (if on-premise), infrastructure, customization, data migration, training, ongoing maintenance and support, upgrades, and even the cost of internal resources dedicated to the project.

For small manufacturers, understanding and accurately estimating TCO is paramount for addressing budget constraints in small manufacturing ERP projects. A system with a low initial cost might appear attractive, but hidden fees, expensive maintenance contracts, or extensive customization requirements down the line can quickly inflate its TCO. Conversely, a system with a slightly higher upfront investment might offer lower long-term costs due to superior support, easier upgrades, or better out-of-the-box functionality. Therefore, thorough TCO calculation, factoring in all potential expenses, empowers small manufacturers to make informed decisions, comparing apples to apples and ensuring that the chosen solution remains financially viable over its operational lifespan, preventing nasty surprises from hidden ERP costs.

Cloud-Based ERP vs. On-Premise: A Budget-Friendly Choice for SMEs

The architectural choice between cloud-based (SaaS) ERP and traditional on-premise ERP systems profoundly impacts a small manufacturer’s budget. For companies focused on addressing budget constraints in small manufacturing ERP projects, cloud-based solutions have emerged as a distinctly budget-friendly choice, offering a compelling alternative to the capital-intensive nature of on-premise deployments. With cloud ERP, the software and data are hosted by the vendor on their servers, accessible via the internet. This model drastically reduces the upfront investment required.

Firstly, there’s no need to purchase expensive servers, networking equipment, or invest in data center infrastructure. These capital expenditures are eliminated, turning large upfront costs into predictable, manageable operational expenses (OpEx) through subscription fees. Secondly, the responsibility for system maintenance, security updates, and regular backups shifts from the manufacturing company to the ERP vendor, significantly reducing internal IT overhead and the need for specialized personnel. This frees up valuable internal resources and reduces ongoing operational costs. The cloud ERP benefits extend to scalability, allowing businesses to easily adjust user licenses and functionalities as they grow without major infrastructure overhauls. This flexibility in SaaS ERP pricing models makes cloud solutions particularly attractive for small manufacturers seeking powerful ERP capabilities without breaking the bank, transforming how they approach technology investments.

Phased Implementation Strategies: Breaking Down the ERP Project for Manageable Budgets

One of the most effective methods for addressing budget constraints in small manufacturing ERP projects is adopting a phased implementation strategy. Instead of attempting a “big bang” approach, where all functionalities are rolled out simultaneously, a phased approach breaks the project into smaller, more manageable stages. This strategy not only mitigates risk but, crucially, spreads the financial outlay over time, making it easier for small manufacturers with limited capital to absorb the costs.

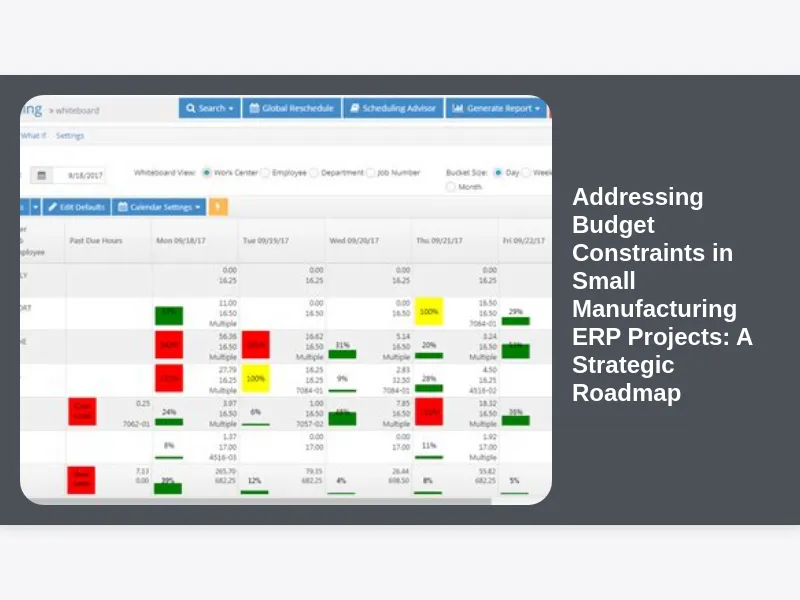

A typical phased implementation might start with core functionalities that address the most pressing operational bottlenecks, such as inventory management, production scheduling, or sales order processing. Once these modules are successfully implemented and users are proficient, subsequent phases can introduce more advanced features like quality control, shop floor data collection, or advanced planning. This modular ERP deployment allows the business to start realizing benefits and potential ROI from the initial phases, which can then help fund subsequent stages. It also provides valuable learning opportunities, allowing the company to fine-tune its processes and user training before committing to the full scope. By embracing staged ERP implementation, small manufacturers can avoid overwhelming their budgets and their teams, ensuring a smoother transition and a more sustainable investment path, turning a large project into a series of achievable milestones.

Leveraging Open-Source ERP Options: Exploring Cost-Effective Alternatives

For small manufacturers facing stringent budget limitations, leveraging open-source ERP options presents a compelling and often overlooked avenue for implementing a robust management system. Unlike proprietary software, open-source ERP systems are developed collaboratively, and their source code is freely available for anyone to use, modify, and distribute. This fundamental difference has significant implications for cost. The most obvious benefit is the elimination of hefty licensing fees, which can constitute a substantial portion of a proprietary ERP’s initial cost.

While open-source ERP systems are “free” in terms of software licenses, they are not entirely without cost. Businesses will still incur expenses related to implementation, customization, data migration, training, and ongoing support, which often require engaging specialized consultants. However, these costs are typically lower than those associated with proprietary systems because the core software itself is free. Furthermore, the flexibility to customize the code allows manufacturers to tailor the system precisely to their unique processes without being constrained by vendor-specific limitations, potentially saving money on expensive proprietary customizations. Examples like Odoo and ERPNext are gaining traction, offering comprehensive functionalities suitable for open source ERP for manufacturing. By carefully evaluating their internal IT capabilities and willingness to engage with the open-source community, small manufacturers can find a highly cost-effective and adaptable solution for addressing budget constraints in small manufacturing ERP projects.

Considering Industry-Specific ERP Solutions: Why Niche Can Be More Cost-Effective

When addressing budget constraints in small manufacturing ERP projects, it’s tempting to gravitate towards generic ERP solutions that promise broad applicability. However, a strategic, often more cost-effective approach, is to consider industry-specific ERP solutions. These specialized systems are designed from the ground up to address the unique processes, regulatory requirements, and operational nuances inherent to a particular manufacturing sector, be it discrete, process, make-to-order, or job shop manufacturing.

The inherent advantage of a niche ERP software lies in its “out-of-the-box” fit. Because it’s built for a specific industry, it typically requires less customization than a generic system to align with a small manufacturer’s workflows. Less customization directly translates to lower implementation costs, shorter deployment times, and reduced risk of project overruns. Furthermore, the learning curve for users can be significantly flatter, as the terminology, reports, and functionalities resonate directly with their daily tasks. Vendors of manufacturing-specific ERP solutions also tend to have deep domain expertise, offering more relevant support and guidance throughout the project. This specialized knowledge can be invaluable for small businesses that lack extensive internal IT or consulting resources, ultimately making the entire project more efficient and budget-friendly. By avoiding the need to adapt a generic system to unique manufacturing challenges, industry-specific solutions become a highly pragmatic choice for cost-conscious small manufacturers.

Optimizing Scope to Control Costs: Focusing on Essential Functionalities First

One of the most common reasons for budget overruns in ERP projects, particularly for small manufacturers, is scope creep – the uncontrolled expansion of the project’s features and requirements beyond its initial objectives. For effective addressing budget constraints in small manufacturing ERP projects, a rigorous focus on optimizing scope to control costs is absolutely critical. This means identifying and prioritizing the most essential functionalities that will deliver the greatest immediate impact and return on investment, deferring “nice-to-have” features for future phases.

Before beginning the selection process, small manufacturers should conduct a thorough internal assessment to pinpoint their most significant operational pain points. Is it inventory accuracy, production scheduling, quality control, or financial reporting? The ERP system should initially be configured to solve these core issues. This focused approach, often termed core ERP modules implementation, ensures that resources are directed towards areas that will yield the quickest and most tangible benefits. It’s about getting the foundational elements right, establishing a stable platform, and then, once the system is live and delivering value, considering expansion. This disciplined ERP scope management prevents the project from becoming bloated, keeping implementation times shorter, consulting fees lower, and user training more streamlined. By saying “no” to non-essential features in the initial rollout, small manufacturers can successfully implement an ERP within their budget and build a solid foundation for future growth.

The Power of Strong Vendor Partnerships: Negotiating and Finding the Right Fit

The relationship a small manufacturer establishes with its ERP vendor can significantly impact the project’s financial outcome and overall success. For addressing budget constraints in small manufacturing ERP projects, cultivating strong vendor partnerships is not merely about selecting a software provider; it’s about finding a strategic ally who understands the unique challenges and financial realities of an SME. This partnership begins with thorough due diligence and extends through negotiation, implementation, and long-term support.

When engaged in ERP vendor selection, small manufacturers should prioritize vendors who demonstrate a clear understanding of their industry, size, and specific pain points. Look for providers who offer flexible pricing models, transparent cost structures, and a proven track record with similar-sized businesses. Don’t shy away from negotiating ERP contracts; many vendors are willing to adjust terms, especially if they see a long-term relationship potential. This could involve discounted implementation services, extended payment terms, or bundled support packages. Beyond pricing, evaluate the vendor’s commitment to ongoing support, training resources, and their responsiveness. A vendor that offers readily available, cost-effective support and proactively assists with adoption can save significant money in the long run by preventing costly downtime or the need for expensive external consultants. A true partner will work with you to find solutions that fit your budget, ensuring mutual success.

Unlocking Government Grants and Incentives: External Funding Opportunities for Tech Upgrades

For small manufacturing businesses, addressing budget constraints in small manufacturing ERP projects can often extend beyond internal cost-saving measures to include external funding opportunities. Many governments, at both national and regional levels, recognize the critical role that small manufacturers play in economic growth and job creation. To stimulate innovation, improve competitiveness, and encourage digital transformation, various government grants and incentives are often made available for technology upgrades, including ERP system implementations.

These programs can take several forms: direct grants that provide non-repayable funds, tax credits for investments in specific technologies, or low-interest loans designed to support SME growth. Eligibility criteria vary widely, but typically focus on factors such as company size, industry sector, job creation potential, and the innovative nature of the technology investment. For instance, programs aimed at modernizing manufacturing, promoting sustainable practices, or enhancing export capabilities might view an ERP implementation favorably as it underpins these objectives. Small manufacturers should proactively research available manufacturing grants and SME technology funding opportunities through government websites, chambers of commerce, and industry associations. While the application process can be rigorous, securing external funding can significantly alleviate the financial burden of an ERP project, making an otherwise daunting investment much more achievable and accelerating the adoption of critical business tools.

Calculating the Return on Investment (ROI) for ERP: Justifying the Expense

For many small manufacturing businesses, the most persuasive argument for addressing budget constraints in small manufacturing ERP projects and ultimately investing in an ERP system is a clear demonstration of its financial benefits. This requires a robust calculation of the Return on Investment (ROI) for ERP. While the costs are tangible and often immediate, the benefits, though significant, can sometimes feel intangible or accrue over time. A well-articulated ROI analysis transforms the ERP project from a mere expense into a strategic investment with measurable financial gains.

Calculating ERP ROI involves identifying all potential cost savings and revenue enhancements resulting from the ERP implementation and comparing them against the total cost of ownership. On the cost-saving side, an ERP can lead to reduced inventory levels, optimized production schedules, decreased waste, lower administrative overhead, and improved procurement efficiency. Revenue enhancements might stem from faster order fulfillment, improved customer satisfaction, better sales forecasting, and the ability to take on more complex or customized orders. Tools like an ERP ROI calculator can help structure this analysis, providing a framework to quantify benefits such as labor savings, reduced material costs, and increased throughput. By clearly measuring ERP success in financial terms, small manufacturers can effectively justify the investment to stakeholders, secure internal buy-in, and reinforce the notion that ERP is not just a cost, but a powerful engine for profitability and sustainable growth.

Training and Change Management on a Budget: Maximizing User Adoption Affordably

Beyond the software and implementation, the success of an ERP project hinges critically on user adoption. If employees aren’t adequately trained or resistant to change, even the most sophisticated system will fail to deliver its promised benefits. However, for small manufacturers addressing budget constraints in small manufacturing ERP projects, extensive, high-cost training programs and dedicated change management consultants might seem out of reach. The good news is that effective training and change management on a budget are entirely achievable with strategic planning.

Firstly, leverage your ERP vendor’s standard training resources. Many cloud-based ERP solutions offer comprehensive online academies, video tutorials, and documentation that users can access at their own pace, significantly reducing the need for expensive in-person sessions. Secondly, identify internal champions – tech-savvy employees who can be trained as super-users. These individuals can then train their colleagues, acting as internal support and driving user adoption strategies. This peer-to-peer learning model is often more effective and cost-efficient. Thirdly, focus on practical, role-based training that directly relates to each user’s daily tasks, avoiding overwhelming them with unnecessary features. Phased implementations also aid change management by introducing new functionalities incrementally. Finally, open and transparent communication throughout the project, explaining the “why” behind the ERP, can significantly reduce resistance and foster a positive attitude towards the new system, proving that effective organizational change doesn’t always require a premium price tag.

Integrating with Existing Systems: A Cost-Saving Approach to ERP Deployment

For many small manufacturers, a complete rip-and-replace of all existing software systems can be an unnecessarily expensive and disruptive undertaking. A more pragmatic and cost-saving approach for addressing budget constraints in small manufacturing ERP projects often involves strategically integrating with existing systems. Instead of forcing all functionalities into the new ERP, evaluate which legacy systems are performing well, are cost-effective, and have a high degree of user familiarity. This could include specialized CAD/CAM software, CRM systems, or even certain financial applications.

The goal is to connect the ERP system with these existing platforms, allowing for seamless data flow without requiring a complete overhaul of every component. For instance, an ERP might handle core manufacturing and financial processes, while still integrating with a preferred CAD system for design, eliminating the need to re-implement design capabilities within the ERP itself. This ERP integration best practices approach reduces the scope of the ERP implementation, thereby lowering customization costs, data migration efforts, and user training requirements. Modern ERP systems and integration platforms offer robust APIs (Application Programming Interfaces) that simplify connections. While there will be some cost associated with integration development, it often pales in comparison to the expense and disruption of replacing a perfectly functional, albeit specialized, legacy system. This strategy allows small manufacturers to leverage their existing technology investments while still gaining the comprehensive benefits of an integrated ERP, transforming legacy system integration into a budget-conscious advantage.

Post-Implementation Support and Maintenance Costs: Budgeting for Ongoing Expenses

The financial commitment to an ERP system doesn’t end once the implementation is complete and the system is live. Post-implementation support and maintenance costs are an essential part of the Total Cost of Ownership (TCO) that small manufacturers must diligently budget for. Failing to account for these ongoing expenses can lead to unexpected financial strain and compromise the long-term success of the ERP investment. For addressing budget constraints in small manufacturing ERP projects, it’s crucial to understand the various components of these recurring costs.

Typically, these costs include software licensing fees (for cloud solutions, this is the recurring subscription), annual maintenance fees for on-premise software, technical support plans, and potential upgrade costs. While cloud ERP solutions bundle many of these into a single subscription, on-premise systems often require separate contracts for software updates, bug fixes, and technical assistance. Small manufacturers must carefully evaluate the terms of these agreements, understanding what is included in standard support versus what constitutes an additional billable service. Furthermore, internal resources dedicated to system administration, ongoing user training, and minor customizations also represent an ongoing cost. Proactively budgeting for these long-term ERP costs and negotiating favorable support agreements with the vendor can prevent future financial surprises. Investing in adequate post-implementation support ensures that the ERP system continues to perform optimally, remains secure, and evolves with the business needs, protecting the initial investment and maximizing its long-term value.

The Long-Term Value of ERP for Small Manufacturing: Beyond the Initial Investment

While the immediate focus for small manufacturers is often on addressing budget constraints in small manufacturing ERP projects and managing the upfront costs, it is imperative to shift the perspective towards the profound long-term value of ERP for small manufacturing. An ERP system, when properly implemented and utilized, is not merely an expense but a strategic asset that underpins sustainable growth, enhances competitiveness, and future-proofs the entire operation. The return on investment extends far beyond direct cost savings, touching every aspect of the business.

Over time, an ERP system provides unparalleled operational visibility, allowing manufacturers to make data-driven decisions that optimize production, improve inventory turns, and reduce waste. It enhances customer satisfaction through faster order fulfillment and improved product quality. Furthermore, an ERP system provides a scalable foundation, enabling businesses to expand their product lines, enter new markets, or increase production volumes without encountering the limitations of fragmented legacy systems. It fosters innovation by freeing up resources from manual tasks and providing real-time data for analysis. The ability to quickly adapt to market changes, comply with new regulations, and integrate emerging technologies all contribute to the strategic ERP benefits. By investing in a robust ERP, small manufacturers aren’t just buying software; they’re investing in a resilient, efficient, and adaptable future for their business, solidifying their competitive edge and enabling sustained profitability.

Avoiding Common Budget Pitfalls: Safeguarding Your ERP Investment

Even with the best intentions and meticulous planning, ERP projects for small manufacturers can fall victim to common pitfalls that lead to budget overruns and diminished ROI. Addressing budget constraints in small manufacturing ERP projects proactively involves understanding and actively avoiding these traps. One of the most prevalent issues is underestimating the true scope and complexity of the project, especially regarding data migration and integration. Businesses often underestimate the time and effort required to cleanse, transform, and transfer data from old systems to the new ERP, leading to unexpected costs and delays.

Another significant pitfall is succumbing to excessive customization. While some tailoring might be necessary, over-customizing an ERP system can drastically inflate costs, complicate upgrades, and tie the business too closely to a specific vendor or consultant. It’s crucial to challenge every customization request and prioritize out-of-the-box functionality wherever possible. Lack of robust project management and inadequate internal resource allocation are also frequent causes of ERP budget overruns. Without a dedicated project manager and sufficient commitment from internal staff, tasks can fall behind schedule, requiring expensive external intervention. Finally, neglecting to budget for sufficient user training and change management can lead to low adoption rates, rendering the system largely ineffective and wasting the initial investment. By being aware of these common ERP mistakes and implementing strategies to mitigate them, small manufacturers can safeguard their investment and ensure the project remains within financial parameters.

The Human Element: Internal Resources as a Cost Factor in ERP Projects

While software licenses and implementation services often dominate budget discussions for addressing budget constraints in small manufacturing ERP projects, the human element within the small manufacturing firm itself represents a significant, often underestimated, cost factor. The time and effort required from internal staff for an ERP project are substantial, and if not properly accounted for, can lead to project delays, internal stress, and unforeseen expenses. These are not “hidden” costs, but rather resources diverted from daily operations.

Establishing an internal ERP project team means pulling key personnel away from their primary responsibilities. These individuals will be involved in defining requirements, participating in software selection, attending training sessions, testing the system, migrating data, and eventually becoming super-users. For a small manufacturer, where every employee wears multiple hats, this diversion of labor can impact daily production and customer service if not carefully managed. It’s crucial to acknowledge this internal resource allocation as a legitimate cost and plan for it. This might involve temporarily hiring contractors to cover daily tasks, rescheduling production, or carefully distributing the workload. Over-relying on external consultants without sufficient internal engagement can also be more expensive in the long run, as the knowledge transfer won’t be as deep. By realistically assessing the internal capacity and planning for the human capital investment, small manufacturers can better control the true cost of their ERP project, preventing internal bottlenecks and ensuring a smoother transition.

Future-Proofing Your ERP Investment: Scalability and Adaptability for Growth

For small manufacturing businesses, addressing budget constraints in small manufacturing ERP projects isn’t just about managing today’s expenses; it’s also about making a strategic investment that will continue to deliver value as the business evolves. This necessitates prioritizing future-proofing your ERP investment by selecting a system that offers inherent scalability and adaptability for growth. A solution that perfectly fits current needs but cannot accommodate future expansion will quickly become a new bottleneck, potentially requiring another costly replacement down the line.

When evaluating ERP options, small manufacturers should consider their growth projections: anticipated increases in production volume, expansion into new markets, new product lines, or additional facilities. Does the ERP system support an increased number of users without significant infrastructure upgrades (for on-premise) or prohibitive licensing costs (for cloud)? Can it easily integrate with new technologies or systems that might become critical in the future, such as IoT devices, advanced analytics tools, or e-commerce platforms? Modern, cloud-based ERPs are typically designed with this flexibility in mind, offering modular components that can be added as needed and an infrastructure that scales seamlessly. Choosing a vendor with a clear roadmap for product development and a commitment to innovation also ensures that the ERP system will remain relevant and capable of supporting a future-ready manufacturing operation. This foresight in selection, while potentially influencing initial budget slightly, pays dividends by preventing expensive system migrations and ensuring the ERP remains a growth enabler, not a limitation.

Making the Business Case for ERP to Stakeholders: Securing Essential Buy-In

Even with a thoroughly planned budget and a clear strategy for addressing budget constraints in small manufacturing ERP projects, the initiative can falter without the full support and understanding of key stakeholders. For small manufacturing firms, this often means convincing owners, investors, and senior management of the strategic necessity and financial viability of an ERP system. Making the business case for ERP to stakeholders is therefore a critical step, requiring clear communication and a focus on tangible benefits.

The business case should articulate not just the projected costs, but more importantly, the quantifiable benefits and the potential risks of inaction. This involves presenting a compelling ERP justification that highlights how the system will solve specific pain points, improve efficiency, reduce operational costs, enhance decision-making, and ultimately contribute to the company’s profitability and competitive advantage. Leveraging the ROI calculation (as discussed previously) is crucial here, translating operational improvements into financial gains. Furthermore, addressing concerns about implementation disruption, training, and ongoing support transparently will build trust. Demonstrating how the ERP aligns with the company’s long-term strategic goals – such as increasing market share, improving product quality, or expanding global reach – is essential for securing C-level buy-in. By framing the ERP as an investment in the company’s future rather than just a cost, small manufacturers can win over skeptical stakeholders and ensure the necessary support and resources for a successful project.

Conclusion: ERP as a Catalyst for Growth, Not Just an Expense

For small manufacturing businesses, the journey of addressing budget constraints in small manufacturing ERP projects is less about finding the cheapest solution and more about discovering the smartest investment. It’s about recognizing that ERP is not merely an expense, but a powerful catalyst for growth, efficiency, and sustained profitability. The landscape of ERP solutions has evolved dramatically, offering an unprecedented range of affordable, scalable, and industry-specific options designed specifically to meet the unique needs and financial realities of smaller enterprises.

By adopting a strategic mindset that prioritizes understanding the true Total Cost of Ownership, embracing phased implementations, exploring cloud and open-source alternatives, optimizing scope, and leveraging strong vendor partnerships, small manufacturers can demystify the perceived high cost of ERP. Furthermore, by actively seeking government grants, rigorously calculating ROI, and proactively managing internal resources, they can transform a daunting capital expenditure into a well-managed, value-driven investment. The modern ERP system empowers small manufacturers to compete effectively, innovate rapidly, and build a resilient foundation for the future. The conversation should shift from “Can we afford ERP?” to “Can we afford not to invest in ERP?” The answer, with careful planning and strategic execution, is a resounding affirmation of its accessibility and indispensable value.