Embarking on the journey to select an Enterprise Resource Planning (ERP) system is a significant undertaking for any business, but for small manufacturing operations, the stakes are particularly high. The right system can propel growth, streamline operations, and provide crucial insights, while the wrong choice can lead to wasted resources and ongoing frustration. In today’s rapidly evolving digital landscape, Cloud ERP has emerged as the preferred solution, offering unparalleled flexibility, scalability, and accessibility. This extensive guide is designed to help small manufacturers navigate the complex process of comparing Cloud ERP vendors for small manufacturing needs, offering a detailed look at what to consider, what to expect, and how to make an informed decision that will empower your business for years to come.

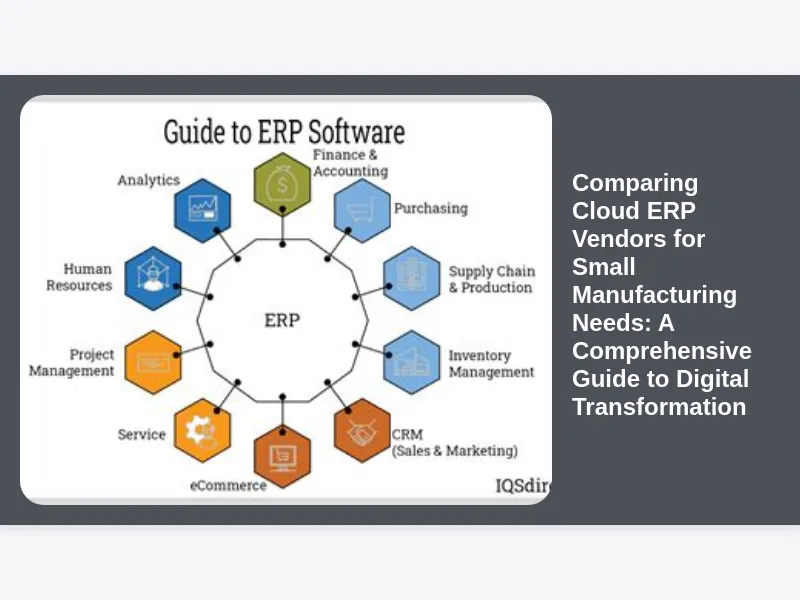

The shift from on-premise legacy systems to cloud-based solutions is not merely a trend; it represents a fundamental change in how businesses manage their core operations. For small manufacturers, this means access to powerful tools previously reserved for larger enterprises, but without the prohibitive upfront costs and IT infrastructure requirements. The ability to manage everything from inventory and production scheduling to financials and customer relations from a single, integrated platform can transform efficiency and competitiveness. However, with a multitude of vendors offering diverse features and pricing models, understanding the nuances of each offering becomes paramount. This article aims to demystify that process, providing actionable insights to help you identify the perfect technological partner.

Why Cloud ERP is a Game-Changer for Small Manufacturing Operations

The adoption of Cloud ERP represents a pivotal moment for small manufacturing businesses seeking to optimize their operations and secure a competitive edge. Unlike traditional on-premise systems, which demand significant upfront investment in hardware, software licenses, and ongoing IT maintenance, Cloud ERP operates on a subscription model, where the vendor hosts and manages the infrastructure. This fundamental difference translates into a host of benefits that are particularly attractive to smaller firms with limited capital and IT resources, making it an essential consideration when comparing Cloud ERP vendors for small manufacturing needs.

Firstly, the scalability of Cloud ERP is a massive advantage. Small manufacturers often experience fluctuating demands and unpredictable growth patterns. A cloud-based system can effortlessly scale up or down to meet these changing needs without requiring substantial hardware upgrades or complex software reconfigurations. This agility ensures that as your production volume increases or your product lines expand, your ERP system can keep pace, preventing bottlenecks and supporting seamless growth. Furthermore, the accessibility of Cloud ERP means that critical business data and functionalities are available from anywhere, at any time, on any device with an internet connection. This empowers remote teams, facilitates collaboration across different departments or locations, and enhances overall operational flexibility, which is crucial for modern, dynamic manufacturing environments.

Understanding the Core Needs of a Small Manufacturing Business

Before diving into the specifics of various Cloud ERP vendors, it is crucial for any small manufacturing business to have a crystal-clear understanding of its own unique operational needs, pain points, and strategic objectives. Without this foundational self-assessment, the process of comparing Cloud ERP vendors for small manufacturing needs can become overwhelming and unfocused. Small manufacturers, by their nature, often grapple with specific challenges that distinguish them from larger enterprises or service-based businesses, and an effective ERP solution must directly address these.

Typically, these businesses need robust capabilities to manage their entire production lifecycle, from raw material procurement to finished goods delivery. This includes precise inventory control, ensuring that the right components are available at the right time without excessive stock levels tying up capital. Production planning and scheduling are also critical, requiring tools that can optimize machine utilization, balance workloads, and track progress against tight deadlines. Beyond the shop floor, small manufacturers often struggle with achieving comprehensive visibility across their supply chain, managing customer orders efficiently, and maintaining accurate financial records for cost control and profitability analysis. An ideal Cloud ERP system must offer integrated solutions to these core areas, providing a unified view of the business and enabling data-driven decision-making.

Key Features to Look For: Essential ERP Modules for Production

When comparing Cloud ERP vendors for small manufacturing needs, the depth and breadth of their production-specific modules are often the make-or-break factors. A generic ERP system might cover basic accounting, but small manufacturers require specialized functionalities that address the intricacies of their operational environment. These essential modules are designed to streamline the entire production process, from initial design to final assembly, ensuring efficiency, quality, and timely delivery.

One of the most vital components is robust Bill of Materials (BOM) management. This module accurately defines all the components, sub-assemblies, and quantities required to produce a finished product, including routing steps and work instructions. An advanced BOM feature can handle multiple revisions, engineering changes, and even configure-to-order scenarios, which are common in custom or semi-custom manufacturing. Closely linked is production planning and scheduling, which allows manufacturers to forecast demand, plan material requirements (MRP), and schedule production orders across various work centers. This optimizes resource allocation, minimizes idle time, and helps meet customer delivery dates. Furthermore, shop floor control capabilities, including real-time data collection from machines and operators, are indispensable for tracking work in progress, monitoring quality, and identifying bottlenecks as they occur. Without these specialized functionalities, a Cloud ERP system simply cannot provide the comprehensive support a small manufacturing operation truly needs.

Financial Management and Accounting Integration in Cloud ERP Systems

Beyond the shop floor, the financial health and precise accounting practices are paramount for any small manufacturing business. When comparing Cloud ERP vendors for small manufacturing needs, it is crucial to scrutinize their financial management and accounting integration capabilities. An integrated Cloud ERP system ensures that all operational data, from sales orders and production costs to inventory movements, flows seamlessly into the financial ledger, providing a holistic and accurate picture of the company’s fiscal standing. This eliminates manual data entry, reduces errors, and significantly accelerates the closing process at month or quarter end.

Core accounting functionalities typically include general ledger, accounts payable, accounts receivable, and fixed asset management. For manufacturers, however, the ability to track costs meticulously is particularly important. This means robust features for job costing, standard costing, and actual costing, allowing businesses to understand the true cost of producing each item, including direct materials, direct labor, and overhead. Furthermore, advanced financial reporting tools are essential for generating detailed profit and loss statements, balance sheets, and cash flow reports, which are vital for strategic planning and compliance. The system should also support budgeting and forecasting, enabling small manufacturers to set financial targets, monitor performance against those targets, and make informed decisions about future investments or resource allocation. Without strong, integrated financial capabilities, the “ERP” in Enterprise Resource Planning falls short of its promise, leaving critical financial insights siloed and difficult to access.

Inventory, Warehouse, and Supply Chain Optimization with Cloud ERP

For small manufacturers, efficient management of inventory, warehouse operations, and the entire supply chain is not just a best practice; it is often the cornerstone of profitability and customer satisfaction. Therefore, when comparing Cloud ERP vendors for small manufacturing needs, their prowess in these areas must be meticulously evaluated. A robust Cloud ERP system can transform these traditionally complex and often manual processes into streamlined, data-driven operations, significantly reducing costs and improving responsiveness.

At its core, an effective ERP system offers real-time inventory visibility across all locations, from raw materials to work-in-progress and finished goods. This includes features like lot and serial number tracking, expiration date management, and inventory valuation methods. Paired with this, sophisticated warehouse management system (WMS) functionalities, even if simplified for smaller operations, can optimize storage space, guide picking and packing processes, and improve shipping accuracy. Beyond internal operations, the supply chain management (SCM) capabilities of a Cloud ERP are vital. This includes tools for demand forecasting, supplier relationship management, purchase order generation, and even vendor performance tracking. By integrating these functions, manufacturers can minimize stockouts, reduce carrying costs, negotiate better terms with suppliers, and ultimately deliver products to customers more reliably and efficiently. A system that can intelligently manage inventory turns, automate reorder points, and provide clear insights into supplier performance will be an invaluable asset to any growing manufacturing business.

Customer Relationship Management (CRM) and Sales Order Processing within ERP

While manufacturing prowess is often seen as an internal function, the ability to effectively manage customer relationships and streamline sales order processing is equally critical for the growth and sustainability of small manufacturing businesses. When comparing Cloud ERP vendors for small manufacturing needs, it’s imperative to consider how well their systems integrate CRM and sales order management capabilities. A truly holistic ERP solution extends beyond the factory floor, encompassing the entire customer lifecycle from initial inquiry to post-sale support.

Integrated CRM features within an ERP system allow manufacturers to centralize customer data, track interactions, manage leads, and oversee sales opportunities. This means that everyone from sales representatives to production planners has access to the most current customer information, facilitating personalized service and improving responsiveness. Furthermore, seamless sales order processing is essential. This includes the ability to easily create quotes, convert them into sales orders, check product availability, and manage pricing and discounts. When sales orders are directly linked to inventory and production planning modules, it ensures that promised delivery dates are realistic and that production schedules are aligned with customer demand. This level of integration reduces manual errors, accelerates the order-to-cash cycle, and ultimately enhances customer satisfaction. For small manufacturers looking to build strong client relationships and efficiently manage their sales pipeline, a Cloud ERP system that bridges the gap between production and customer-facing activities is an undeniable advantage.

Popular Cloud ERP Vendors: A General Overview for Small Manufacturers

The market for Cloud ERP solutions is vast and diverse, with numerous vendors vying for the attention of small manufacturing businesses. Each vendor brings its own philosophy, feature set, and target audience to the table, making the process of comparing Cloud ERP vendors for small manufacturing needs both challenging and rewarding. While a deeper dive into specific systems will follow, it’s beneficial to start with a general overview of some of the more prominent players that frequently appear on the radar of small to mid-sized manufacturers.

Vendors like Acumatica, Oracle NetSuite, Microsoft Dynamics 365 Business Central, and SAP Business One/ByDesign are widely recognized for their comprehensive offerings. Acumatica, for instance, is often praised for its flexible licensing model and strong manufacturing capabilities, particularly for make-to-order and project-centric production. NetSuite, a pioneer in cloud ERP, provides a highly integrated suite covering virtually every business function, making it suitable for growing companies that envision an all-in-one solution. Microsoft Dynamics 365 Business Central leverages its strong integration with other Microsoft products, offering a familiar user experience and robust functionality for a wide range of industries, including manufacturing. SAP, with its Business One and ByDesign platforms, targets the SMB market with scaled-down versions of its enterprise-grade solutions, focusing on best practices and industry-specific templates. While these are just a few examples, understanding their general positioning helps set the stage for a more detailed comparison tailored to specific manufacturing requirements.

Deep Dive: Acumatica Cloud ERP for Manufacturing

Acumatica has carved out a significant niche in the Cloud ERP market, particularly appealing to small and mid-sized manufacturers due to its flexibility, comprehensive manufacturing suite, and unique consumption-based licensing model. When comparing Cloud ERP vendors for small manufacturing needs, Acumatica often stands out for its adaptability to complex manufacturing processes, making it a strong contender for businesses with evolving or specialized production requirements. Its architecture is designed to be highly configurable, allowing manufacturers to tailor the system to their specific workflows without extensive custom coding.

The Acumatica Manufacturing Edition provides a robust set of modules that cover the entire production lifecycle. This includes advanced capabilities for production orders, material requirements planning (MRP), master production scheduling (MPS), and detailed shop floor control. It excels in managing diverse manufacturing modes, such as make-to-stock, make-to-order, engineer-to-order, and even project-centric manufacturing, offering a level of sophistication that smaller operations often find invaluable for managing custom jobs. Beyond production, Acumatica seamlessly integrates financial management, inventory control, distribution, CRM, and project accounting, providing a unified view of the business. Its emphasis on user experience and the ability to deploy on various cloud platforms (public, private, or hybrid) further enhance its appeal. For small manufacturers who prioritize a scalable, adaptable solution that can grow with their specific needs and potentially complex production scenarios, Acumatica warrants a very close look in their evaluation process.

Deep Dive: Oracle NetSuite for Small and Mid-Market Manufacturers

Oracle NetSuite is a formidable player in the Cloud ERP arena, renowned for offering a truly integrated business management suite that spans ERP, CRM, professional services automation (PSA), and e-commerce. For small and mid-market manufacturers, NetSuite presents an “all-in-one” solution that aims to eliminate data silos and provide a single source of truth across the entire organization. When comparing Cloud ERP vendors for small manufacturing needs, NetSuite’s comprehensive nature and global scalability often make it a top consideration for businesses with ambitions for significant growth or international operations.

NetSuite’s manufacturing capabilities are robust, encompassing demand planning, work order management, assembly management, and advanced inventory control. It supports various production strategies, from discrete manufacturing to process manufacturing and even mixed-mode operations. Manufacturers can gain real-time visibility into their production processes, manage bills of materials (BOMs), routings, and resource capacity, all within a unified platform. A key strength of NetSuite is its ability to centralize data from every facet of the business, allowing manufacturers to track costs, monitor performance metrics, and gain insights into profitability at granular levels. This integration extends to supply chain management, ensuring that procurement, inventory, and production are aligned. For small manufacturers looking for a powerful, enterprise-grade system that can support rapid scaling and offers a complete, integrated view of their operations from the ground up, NetSuite offers a compelling, albeit often higher-investment, solution.

Deep Dive: Microsoft Dynamics 365 Business Central for Production-Centric SMBs

Microsoft Dynamics 365 Business Central emerges as a strong contender when comparing Cloud ERP vendors for small manufacturing needs, especially for businesses already embedded in the Microsoft ecosystem. As a cloud-based business management solution designed specifically for small and mid-sized organizations, it offers a comprehensive suite of functionalities that cover financials, sales, service, and, crucially, manufacturing. Its deep integration with other Microsoft products like Office 365, Power BI, and the wider Dynamics 365 platform is a significant draw, providing a familiar user interface and streamlined data flow.

For production-centric SMBs, Business Central offers robust manufacturing capabilities, including production order management, supply planning, capacity planning, and agile manufacturing. It supports various manufacturing modes, allowing businesses to manage everything from assembly to more complex discrete production. Manufacturers can define bills of materials, manage routings, track work-in-progress, and gain insights into production performance. The system facilitates efficient inventory management, ensuring that materials are available when needed and finished goods are tracked accurately. Furthermore, Business Central provides strong financial management tools, allowing manufacturers to monitor costs, analyze profitability, and manage budgets effectively. Its intuitive interface and the vast network of Microsoft partners who can provide tailored implementation and support make it an accessible and scalable option for small manufacturers looking for a reliable, integrated system that leverages the power of the Microsoft cloud.

Deep Dive: SAP Business ByDesign and SAP Business One for Smaller Manufacturing Firms

SAP, a global leader in enterprise software, also caters to the small and mid-sized business (SMB) market with its Cloud ERP offerings: SAP Business ByDesign and SAP Business One. When comparing Cloud ERP vendors for small manufacturing needs, these two distinct products represent SAP’s approach to bringing enterprise-grade capabilities and best practices to smaller firms. While both are designed for SMBs, they offer different deployment models and feature sets, appealing to slightly varying requirements within the small manufacturing segment.

SAP Business ByDesign is a true cloud-native ERP suite, offering a comprehensive, pre-configured solution for financials, CRM, project management, and supply chain, including manufacturing. It’s often favored by small manufacturers looking for a ready-to-use, integrated system that encompasses multiple business functions without extensive customization. Its manufacturing module supports various production processes, from make-to-stock to make-to-order, providing capabilities for production planning, shop floor control, and detailed product costing. SAP Business One, on the other hand, is a more traditional ERP solution that can be deployed on-premise or in the cloud. It is known for its strong core financials, inventory management, and discrete manufacturing functionalities. Business One offers greater flexibility for customization and can be extended with a vast ecosystem of add-ons from SAP partners, making it suitable for small manufacturers with highly specific or evolving needs. Both solutions leverage SAP’s deep industry knowledge to provide robust features, but ByDesign offers a more standardized, immediate cloud experience, while Business One provides greater customization potential and deployment choice, making the distinction important for small manufacturers.

Evaluating Customization and Scalability Options for Growing Manufacturers

For small manufacturing businesses, the ability of a Cloud ERP system to adapt to current processes while also accommodating future growth and evolving needs is paramount. Therefore, when comparing Cloud ERP vendors for small manufacturing needs, a thorough evaluation of their customization and scalability options is non-negotiable. A system that is too rigid will stifle innovation and efficiency, while one that can’t grow with the business will quickly become obsolete.

Customization refers to the ability to tailor the ERP system to specific business processes, terminology, and reporting requirements. This might involve creating custom fields, modifying workflows, designing unique reports, or integrating with other specialized software. While excessive customization can increase implementation costs and complicate upgrades, a certain degree of flexibility is often necessary to ensure the system truly reflects the unique operational nuances of a small manufacturer. Vendors offer varying levels of configurability versus actual coding customization, and understanding these differences is key. Scalability, on the other hand, relates to the system’s capacity to handle increased data volumes, more users, additional locations, and new business units without degrading performance. As a small manufacturer grows, expanding product lines, entering new markets, or acquiring other businesses, the ERP must be able to seamlessly absorb this growth. This involves not only the underlying technical infrastructure of the cloud provider but also the architecture of the ERP application itself. A Cloud ERP that offers modular expansion, flexible licensing, and a robust underlying platform ensures that the investment made today will continue to deliver value as the business matures and expands, safeguarding against the need for a costly re-implementation down the line.

Integration Capabilities: Connecting Your ERP to Other Essential Systems

In today’s interconnected business environment, no software solution operates in isolation. For small manufacturers, the ability of a Cloud ERP system to seamlessly integrate with other essential business applications is a critical factor when comparing Cloud ERP vendors for small manufacturing needs. Many businesses already rely on specialized tools for CAD/CAM, e-commerce, shipping, quality management, or specific industry compliance, and the new ERP must be able to communicate effectively with these existing systems to avoid data silos and manual data re-entry.

Robust integration capabilities ensure that data flows freely and accurately across your technological ecosystem, creating a single source of truth and automating processes. For instance, an integration with a CAD system could automatically pull bill of materials data into the ERP for production planning, or an e-commerce platform could feed sales orders directly into the ERP for fulfillment. Vendors typically offer various methods for integration, including pre-built connectors, APIs (Application Programming Interfaces) for custom development, and integration platforms as a service (iPaaS). It’s important to assess the ease, cost, and reliability of these integration options. A well-integrated ERP system will not only reduce operational inefficiencies but also enhance data accuracy, provide a more complete view of business operations, and empower better decision-making by eliminating the fragmentation of critical information. Without strong integration, even the most powerful ERP can become an island, limiting its overall effectiveness and increasing the administrative burden on your team.

Understanding Total Cost of Ownership (TCO) for Cloud ERP Implementations

When small manufacturers embark on comparing Cloud ERP vendors for small manufacturing needs, a common pitfall is focusing solely on the initial software subscription fees. However, a true understanding of the long-term financial commitment requires a comprehensive analysis of the Total Cost of Ownership (TCO). Cloud ERP, while eliminating large upfront hardware investments, still involves a range of costs that can significantly impact a small business’s budget over the lifespan of the system.

The TCO encompasses not just the recurring software subscription fees, which are typically based on the number of users, modules, and data volume, but also a myriad of other expenditures. Implementation costs can be substantial, including vendor professional services for configuration, data migration from legacy systems, and integration with other applications. Training for employees, both initial and ongoing, is another crucial investment to ensure user adoption and system proficiency. Furthermore, customization or unique development efforts required to tailor the system to specific workflows will add to the overall cost. Don’t forget potential third-party add-on solutions or ongoing support contracts for specialized modules. While Cloud ERP generally offers a lower TCO than on-premise systems due to reduced IT infrastructure and maintenance, it is vital for small manufacturers to get a clear, itemized estimate from vendors for all these components. A thorough TCO analysis will help avoid unexpected expenses down the line and allow for a more accurate comparison of the true financial impact of each Cloud ERP solution.

Implementation Strategies and Vendor Support for a Smooth Transition

The success of a new Cloud ERP system for a small manufacturing business hinges not just on the software’s capabilities, but profoundly on the implementation strategy and the quality of vendor support. When comparing Cloud ERP vendors for small manufacturing needs, evaluating their approach to implementation and their post-go-live support mechanisms is as crucial as scrutinizing the feature set itself. A poorly managed implementation can lead to significant disruptions, user frustration, and failure to realize the system’s potential benefits.

Vendors typically offer various implementation methodologies, ranging from agile, phased rollouts to more traditional “big bang” approaches. For small manufacturers, a phased approach often proves more manageable, allowing teams to adapt gradually and providing opportunities for adjustments along the way. It’s important to understand the vendor’s or their certified partner’s project management methodology, their experience with similar manufacturing businesses, and their plan for data migration, system configuration, and user training. Post-implementation support is equally critical. What are the service level agreements (SLAs)? What channels are available for support (phone, email, chat)? Is there a dedicated account manager? How are software updates and upgrades handled in the cloud environment? A vendor that provides robust documentation, a responsive support team, and ongoing training resources will significantly ease the transition and ensure that your small manufacturing operation can fully leverage its new Cloud ERP system without being left in the dark when issues arise.

Data Security and Compliance Considerations for Manufacturing ERP

In an era of increasing cyber threats and stringent regulatory landscapes, data security and compliance are non-negotiable considerations when comparing Cloud ERP vendors for small manufacturing needs. Small manufacturers handle a wealth of sensitive data, including proprietary product designs, customer information, financial records, and supply chain details. Ensuring the security and integrity of this data, especially when entrusting it to a cloud provider, is paramount to protecting the business and maintaining trust.

A reputable Cloud ERP vendor will employ robust security measures at multiple layers. This includes physical security of their data centers, network security protocols (firewalls, intrusion detection), data encryption (both in transit and at rest), and strict access controls. It’s essential to inquire about their security certifications (e.g., ISO 27001, SOC 1/2/3 reports) and their disaster recovery and business continuity plans. What happens if there’s an outage? How quickly can data be restored? Furthermore, compliance with industry-specific regulations and general data privacy laws (like GDPR or CCPA) is critical. For manufacturers, this might involve adherence to standards for quality control, traceability, or even export controls. The chosen Cloud ERP system should have features that support these compliance requirements, such as audit trails, electronic signatures, and configurable security roles. A thorough understanding of a vendor’s security posture and commitment to compliance will provide peace of mind and protect your small manufacturing business from potential data breaches and regulatory penalties.

User Experience and Adoption: Ensuring Your Team Embraces the New System

The most feature-rich Cloud ERP system is only as effective as its adoption by the people who use it daily. Therefore, when comparing Cloud ERP vendors for small manufacturing needs, the user experience (UX) and the ease of adoption by your team should be weighed heavily. If employees find the system cumbersome, unintuitive, or difficult to learn, they will resist using it, undermining the entire investment and preventing the realization of expected efficiencies and insights.

A good user experience is characterized by an intuitive interface, clear navigation, and logical workflows that mirror your business processes. Look for systems that offer customizable dashboards, allowing users to prioritize the information most relevant to their role. The learning curve should be manageable, and the vendor should provide comprehensive training resources, whether through online tutorials, user guides, or direct support. Change management is also a critical component of adoption. Small manufacturing teams can be resistant to new technology, especially if they are accustomed to established manual processes or older systems. The vendor or implementation partner should be able to provide guidance on how to introduce the new system effectively, communicate its benefits, and address user concerns. Ultimately, a Cloud ERP that is well-designed from a UX perspective and supported by a strong change management strategy will lead to higher user engagement, fewer errors, and a faster return on investment for your small manufacturing operation.

The Future of Cloud ERP: Emerging Trends for Small Manufacturers

The technological landscape is in constant flux, and the Cloud ERP sector is no exception. As small manufacturing businesses engage in comparing Cloud ERP vendors for small manufacturing needs, it’s wise to consider not just current capabilities but also how each vendor is positioned to incorporate emerging technologies. Staying ahead of the curve can provide a significant competitive advantage, enabling smarter operations and more proactive decision-making.

One of the most impactful trends is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into ERP systems. These technologies can optimize production scheduling by analyzing vast datasets, predict equipment maintenance needs, forecast demand more accurately, and even automate routine tasks like invoice processing or anomaly detection in financial data. Another crucial development is the Internet of Things (IoT), where sensors on shop floor machinery can feed real-time performance data directly into the ERP. This allows for predictive maintenance, real-time quality control, and unparalleled visibility into operational efficiency. Furthermore, advanced analytics and business intelligence tools are becoming more sophisticated, offering small manufacturers deeper insights into profitability, supply chain performance, and customer behavior. As you evaluate vendors, inquire about their roadmap for incorporating these innovations. A forward-thinking Cloud ERP provider will continuously evolve its platform, ensuring your small manufacturing business is equipped with the tools needed to thrive in an increasingly data-driven and automated future.

Making the Right Choice: A Framework for Comparing Cloud ERP Vendors

The culmination of your research and due diligence in comparing Cloud ERP vendors for small manufacturing needs will be the ultimate decision on which system best aligns with your business’s strategic objectives. To simplify this complex process, it is highly beneficial to adopt a structured decision-making framework, moving beyond mere feature checklists to a more holistic evaluation that considers both immediate needs and long-term vision.

Start by clearly defining your requirements, prioritizing them from “must-have” to “nice-to-have.” Engage key stakeholders from across your manufacturing operation—production, finance, sales, and IT—to ensure all perspectives are represented. Once you have a shortlist of vendors, conduct detailed demonstrations, providing them with specific scenarios or use cases relevant to your business (e.g., “show us how you handle a custom production order from quote to delivery”). Pay close attention to the vendor’s reputation, customer references, and financial stability. Evaluate not just the software, but also the partner ecosystem, support offerings, and their vision for future development. Finally, construct a comprehensive TCO model, factoring in all costs from implementation to ongoing support and potential customizations over a 3-5 year period. This structured approach, combined with a deep understanding of your own needs and the detailed insights provided in this guide, will empower your small manufacturing business to make an informed and strategic decision, selecting a Cloud ERP solution that truly drives efficiency, growth, and long-term success.