In the fast-paced world of modern manufacturing, small businesses often find themselves juggling numerous demands, from managing intricate supply chains to optimizing production schedules and ensuring timely deliveries. The traditional methods of relying on spreadsheets, disparate systems, or even pen and paper are no longer sufficient to maintain a competitive edge. This is where the powerful combination of Cloud ERP and Mobile Access to Cloud ERP for Small Manufacturing Managers steps in, offering a transformative solution that can revolutionize how these vital businesses operate. Imagine having the pulse of your entire factory at your fingertips, whether you’re on the shop floor, meeting a client, or even traveling. This isn’t just a futuristic vision; it’s a tangible reality that is reshaping the landscape for small manufacturers worldwide.

The shift towards digital transformation is no longer a luxury but a necessity for survival and growth. Small manufacturing enterprises, often constrained by resources, can uniquely benefit from adopting agile, scalable, and accessible technologies. The ability to make informed decisions quickly, based on real-time data, can be the defining factor between stagnation and significant expansion. We’re going to dive deep into how this powerful synergy can empower you, the small manufacturing manager, to not only overcome daily challenges but also to strategically position your business for sustained success in an increasingly complex market. Get ready to explore a future where efficiency, flexibility, and insights are always within reach.

The Shifting Landscape for Small Manufacturers: Navigating Modern Challenges

Small manufacturing businesses are the backbone of many economies, driving innovation and providing specialized products. However, they face a unique set of challenges that can hinder growth and operational efficiency. Unlike larger enterprises with vast IT departments and budgets, small manufacturers often operate with leaner teams and limited financial resources, making every investment decision critical. They contend with fluctuating raw material costs, the complexities of supply chain management, stringent quality control demands, and intense competition, all while trying to keep their production lines running smoothly and profitably.

Historically, technology solutions designed for manufacturing were often prohibitively expensive or overly complex for smaller players. This led to a reliance on manual processes, isolated software applications, or outdated legacy systems that couldn’t communicate with each other. The result was often fragmented data, delayed decision-making, and a lack of real-time visibility into critical operations. These challenges are precisely why the advent of Mobile Access to Cloud ERP for Small Manufacturing Managers has become such a game-changer, offering a path to overcome these hurdles without requiring a massive upfront investment in IT infrastructure or specialized personnel.

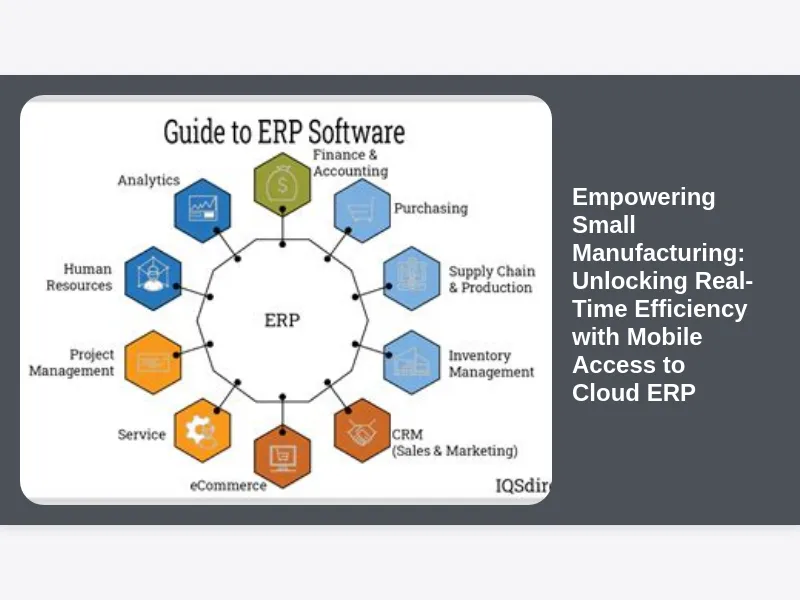

Understanding Cloud ERP: Beyond Traditional Systems for Modern SMBs

Before delving into the mobile aspect, it’s crucial to grasp what Cloud ERP truly entails, especially for small and medium-sized businesses (SMBs). Enterprise Resource Planning (ERP) systems traditionally were robust, on-premise software installations requiring significant capital expenditure, dedicated servers, and a team of IT professionals for maintenance, updates, and troubleshooting. While powerful, this model was often out of reach for small manufacturers, due to the high costs and complexity involved in implementation and ongoing support. It represented a formidable barrier to entry for businesses looking to centralize their operations.

Cloud ERP, by contrast, operates on a subscription-based model, where the software and its associated data are hosted on remote servers managed by a third-party provider. This paradigm shift eliminates the need for physical servers, substantial upfront hardware costs, and the burden of in-house IT management. For small manufacturing managers, this means significantly reduced initial investment and lower total cost of ownership, making sophisticated business management tools accessible and affordable. Furthermore, cloud-based systems are inherently designed for scalability and flexibility, adapting to your business’s needs as it grows without requiring disruptive hardware upgrades or complex migrations.

The Power of Mobile Access: Your Manufacturing Operations in Your Pocket

Imagine a scenario where a sudden rush order comes in, and you’re not at your desk. Or perhaps there’s an issue on the production line, and you need to quickly check inventory levels or a customer’s order status. With traditional ERP systems, this would typically involve rushing back to the office, logging into a desktop computer, and navigating complex interfaces. This is where Mobile Access to Cloud ERP for Small Manufacturing Managers truly shines, transforming your smartphone or tablet into a powerful, portable control center for your entire manufacturing operation. It’s about more than just convenience; it’s about agility and responsiveness.

Mobile access allows you to securely log into your Cloud ERP system from any internet-connected device, providing instant access to critical data and functionalities. This means that whether you’re on the shop floor overseeing production, at a client site discussing new projects, or even attending an industry conference, you remain connected to your business. You can approve purchase orders, check sales forecasts, monitor production metrics, or review financial reports, all from a device that fits in your pocket. This level of on-the-go business management fundamentally changes how small manufacturing managers can react to opportunities and challenges, ensuring they are always informed and empowered to make timely decisions.

Why Small Manufacturing Managers Need This: Bridging the Information Gap

For small manufacturing managers, the daily demands are relentless. They often wear many hats – from overseeing production and managing sales to handling finances and customer service. Without an integrated, accessible system, critical information often resides in silos, leading to delays, miscommunications, and errors. A salesperson might promise a delivery date without knowing the current production schedule, or a manager might approve a raw material order without up-to-date inventory figures, leading to either stockouts or overstock. These information gaps are detrimental to efficiency and profitability.

Mobile Access to Cloud ERP for Small Manufacturing Managers directly addresses these pain points by providing a unified, real-time view of all business operations. It ensures that every stakeholder, from the shop floor supervisor to the sales representative, is working with the most current and accurate data. This immediate access to information allows managers to quickly identify bottlenecks, respond to production issues, and provide accurate information to customers, significantly improving operational agility. In an environment where every minute and every dollar counts, bridging the information gap with mobile ERP becomes not just beneficial, but truly essential for maintaining a competitive edge and fostering sustainable growth.

Real-Time Inventory Management: Preventing Stockouts and Overstocking

One of the most critical aspects of small manufacturing is effective inventory management. Too much inventory ties up valuable capital and increases carrying costs, while too little can lead to production delays, missed sales opportunities, and dissatisfied customers. Traditional inventory tracking methods, often manual or relying on static spreadsheets, are prone to errors and don’t provide the dynamic, real-time insights needed to optimize stock levels. This is a common struggle for small manufacturing managers who need precise data to make smart purchasing and production decisions.

With Mobile Access to Cloud ERP for Small Manufacturing Managers, inventory management is transformed. Managers or their designated staff can use mobile devices to perform cycle counts, scan barcodes for incoming and outgoing goods, and update stock levels instantly from the warehouse floor. This eliminates delays and manual entry errors, providing an accurate, up-to-the-minute view of what’s in stock, where it’s located, and what’s on order. The system can also trigger automated reorder points, send alerts for low stock, and help analyze inventory turns, significantly reducing the risk of both costly overstocking and debilitating stockouts, ensuring that production always has the materials it needs without unnecessary capital expenditure.

Streamlining Production Scheduling and Shop Floor Control: Enhancing Manufacturing Workflow Efficiency

The heartbeat of any manufacturing business is its production line. Efficient production scheduling and tight shop floor control are paramount to meeting delivery deadlines, optimizing resource utilization, and maintaining product quality. For small manufacturers, managing these processes can be a complex juggling act, especially when dealing with varying order sizes, custom specifications, and unexpected equipment issues. Without clear visibility and agile control, bottlenecks can quickly form, leading to delays, wasted resources, and increased operational costs.

Mobile Access to Cloud ERP for Small Manufacturing Managers brings unparalleled visibility and control directly to the shop floor. Supervisors and operators can use tablets or smartphones to access real-time production schedules, view work orders, track job progress, and report completed tasks or issues as they occur. They can log material usage, record quality checks, and even initiate maintenance requests instantly. This immediate data capture feeds directly into the ERP system, allowing managers to monitor key performance indicators (KPIs) from anywhere, identify potential delays, and adjust schedules on the fly. This level of dynamic control not only enhances manufacturing workflow efficiency but also empowers the workforce with the information they need to perform their jobs more effectively.

Sales and Customer Relationship Management (CRM) on the Go: Mobile Sales Tools for Manufacturers

For small manufacturing businesses, building strong customer relationships and efficiently managing the sales cycle are crucial for growth. Sales teams are often on the road, visiting clients, attending trade shows, or following up on leads. Relying on paper notes, memory, or having to return to the office to update CRM systems can lead to lost opportunities, inaccurate quotes, and delayed responses. This disconnect between sales activities and the core manufacturing data can be a significant impediment for small manufacturing managers striving to provide excellent customer service and close deals faster.

Mobile Access to Cloud ERP for Small Manufacturing Managers bridges this gap by integrating CRM functionalities directly into a mobile-accessible platform. Sales representatives can access customer histories, current order statuses, product specifications, and pricing information instantly from their mobile devices. They can generate accurate quotes on the spot, enter new orders directly into the system, and even check inventory availability or production lead times while talking to a client. This not only streamlines the sales process but also significantly enhances customer service, allowing sales teams to be more responsive, informed, and effective, ultimately leading to higher customer satisfaction and increased sales revenue for the manufacturing business.

Financial Visibility and Reporting Anywhere, Anytime: Real-Time Financial Insights for SMBs

Maintaining a clear and accurate picture of a manufacturing business’s financial health is non-negotiable for sustainable growth. Small manufacturing managers often spend considerable time grappling with disparate financial data, attempting to consolidate information from accounting software, payroll systems, and operational reports. This fragmented approach makes it challenging to get a real-time understanding of cash flow, profitability, and cost centers, leading to delayed financial decisions and potentially missed opportunities for cost savings or investment. The ability to quickly review financial data is crucial for agile business management.

With Mobile Access to Cloud ERP for Small Manufacturing Managers, financial management becomes significantly more streamlined and accessible. Managers can securely access comprehensive financial dashboards, view profit and loss statements, balance sheets, and cash flow projections directly from their mobile devices. They can approve invoices, monitor expenses, track budget adherence, and generate customized reports on the fly, empowering them to make informed financial decisions without being tied to a desktop. This instant, real-time financial insight allows for proactive management, better budgeting, and more strategic financial planning, ensuring the small manufacturing business remains financially healthy and resilient against market fluctuations.

Enhanced Collaboration Across Departments and Locations: Unified Operations with Cloud ERP Mobile

In any small manufacturing operation, effective communication and collaboration between different departments are vital. The production floor needs to communicate with inventory, sales needs to communicate with production, and finance needs to understand the impact of all operations. When these departments operate in silos, information bottlenecks and misunderstandings are inevitable, leading to inefficiencies, errors, and wasted resources. Small manufacturing managers often struggle to unify these disparate functions into a cohesive, well-oiled machine.

Mobile Access to Cloud ERP for Small Manufacturing Managers serves as a central nervous system, connecting all these critical departments through a single, accessible platform. For example, a salesperson can check production capacity before promising a delivery date, or a purchasing manager can view real-time inventory levels to avoid over-ordering. Shop floor personnel can update job statuses, which instantly informs planning and sales. This ubiquitous access to shared, real-time data fosters an environment of transparency and accountability, significantly improving cross-departmental communication and collaboration. The result is a more unified, agile, and responsive operation, where every team member is aligned with the overall business objectives, regardless of their physical location within or outside the factory.

Data Security in the Cloud and on Mobile Devices: Addressing Concerns

When considering Mobile Access to Cloud ERP for Small Manufacturing Managers, security is understandably a primary concern. The idea of sensitive business data, including proprietary manufacturing processes, customer information, and financial records, being accessible from mobile devices and hosted off-site can raise questions about data integrity and protection. Small manufacturers, while eager for the benefits, must ensure that their data remains secure against cyber threats, unauthorized access, and data breaches. This apprehension is natural, and addressing it effectively is key to successful adoption.

Reputable Cloud ERP providers invest heavily in robust security infrastructure, often exceeding the capabilities of a small manufacturer’s in-house IT. This includes advanced encryption protocols for data in transit and at rest, multi-factor authentication (MFA), regular security audits, disaster recovery plans, and stringent access controls. For mobile access, best practices include using secure, company-provided devices, implementing Mobile Device Management (MDM) solutions, and ensuring employees adhere to strong password policies and security awareness training. By partnering with trusted cloud vendors and implementing internal security measures, small manufacturing managers can confidently leverage mobile ERP, knowing their valuable data is well-protected against an evolving threat landscape, making the cloud a more secure option than many on-premise setups.

Seamless Integration with Existing Systems: A Holistic Approach for Small Businesses

Many small manufacturing businesses already utilize specialized software for certain functions, such as CAD (Computer-Aided Design), MES (Manufacturing Execution Systems), or dedicated accounting software. The thought of implementing a new Cloud ERP system might bring concerns about data migration, compatibility, and the potential disruption of existing workflows. A common fear for small manufacturing managers is that a new ERP will create more silos, rather than breaking them down, if it cannot communicate effectively with the tools they already rely on daily. A truly holistic solution must be able to work harmoniously with these existing systems.

Modern Cloud ERP solutions are designed with integration in mind. They offer APIs (Application Programming Interfaces) and connectors that facilitate seamless communication with a wide array of third-party applications. This means that instead of replacing all your current systems, your Cloud ERP, with its Mobile Access to Cloud ERP for Small Manufacturing Managers, can act as the central hub, pulling data from and pushing data to your specialized software. For instance, design specifications from CAD can flow into ERP for production planning, and shop floor data from MES can update inventory and production schedules within the ERP. This integrated approach ensures that all systems work in concert, providing a single source of truth and a comprehensive view of operations without requiring a complete overhaul, thus maximizing the utility of existing technology investments.

User Adoption and Training: Ensuring a Smooth Transition and Maximizing ERP ROI

Implementing any new software system, no matter how powerful, is only as successful as its user adoption rate. For small manufacturing managers, getting their teams on board with a new Cloud ERP system, especially one with mobile capabilities, is critical. Resistance to change is a natural human tendency, and if employees find the new system difficult to use, or if they don’t understand its benefits, the investment might not yield its full potential. A smooth transition is crucial for realizing the significant ROI promised by such a transformative tool.

To ensure successful adoption of Mobile Access to Cloud ERP for Small Manufacturing Managers, a strategic approach to training and change management is essential. This includes providing comprehensive, hands-on training tailored to different roles (e.g., sales, production, finance) and highlighting how the new system will make their jobs easier and more efficient. Opting for a Cloud ERP with an intuitive, user-friendly interface is also key, as this significantly reduces the learning curve. Engaging key users in the selection and implementation process can foster a sense of ownership, transforming them into advocates. By prioritizing user education and support, small manufacturers can accelerate the transition, empower their workforce, and ensure that the new mobile ERP system truly becomes an invaluable asset across the entire organization.

Evaluating Cloud ERP Providers: Key Considerations for Small Manufacturers

Choosing the right Cloud ERP provider is a pivotal decision for any small manufacturing manager embarking on this digital transformation journey. The market is saturated with various solutions, each promising different features, pricing models, and levels of support. A hasty decision can lead to buyer’s remorse, an ill-fitting system, and wasted resources. It’s not just about finding an ERP; it’s about finding the right ERP that aligns perfectly with your specific operational needs and long-term business goals, especially when considering the crucial aspect of mobile access.

When evaluating providers for Mobile Access to Cloud ERP for Small Manufacturing Managers, several key factors should be top of mind. Firstly, consider industry-specific functionalities: does the ERP have modules or features tailored to discrete, process, or mixed-mode manufacturing? Secondly, assess scalability: can the system grow with your business without requiring a costly migration? Thirdly, scrutinize the mobile capabilities: how robust and user-friendly are the mobile apps? Do they offer offline functionality? Fourthly, evaluate the vendor’s support, implementation services, and reputation. Finally, compare pricing structures, including subscription fees, implementation costs, and potential add-on module expenses. A thorough evaluation process, involving demos and reference checks, will ensure you select a partner that truly understands and can meet the unique demands of your small manufacturing operation.

The ROI of Mobile Cloud ERP: Tangible Benefits for Growth and Competitive Advantage

While the initial investment in a Cloud ERP system with mobile capabilities might seem significant for a small manufacturer, the return on investment (ROI) can be substantial and multifaceted. The benefits extend far beyond mere cost savings, encompassing improvements in efficiency, productivity, decision-making, and overall business agility. For small manufacturing managers, justifying this investment requires a clear understanding of the tangible and intangible gains that will contribute directly to the company’s bottom line and long-term growth.

The ROI of Mobile Access to Cloud ERP for Small Manufacturing Managers manifests in several key areas. Firstly, operational efficiency dramatically improves through automation, real-time data, and streamlined workflows, leading to reduced labor costs and faster production cycles. Secondly, inventory optimization minimizes carrying costs and prevents stockouts, freeing up capital. Thirdly, enhanced decision-making, fueled by instant access to accurate data, allows managers to react quickly to market changes and identify new opportunities. Fourthly, improved customer satisfaction due to faster order fulfillment and better communication strengthens customer loyalty and drives repeat business. Finally, the scalability of cloud solutions allows the business to grow without significant IT overhaul, providing a competitive advantage and preparing the company for future challenges. These cumulative benefits translate into increased profitability, improved cash flow, and a stronger market position for the small manufacturer.

Future-Proofing Your Manufacturing Business with Scalable Solutions

The manufacturing landscape is continuously evolving, with new technologies like AI, IoT, and advanced robotics emerging at a rapid pace. For small manufacturing managers, the challenge isn’t just to adopt current best practices but also to ensure their operations are agile enough to embrace future innovations. Investing in a rigid, on-premise system that quickly becomes obsolete is a risk that most small businesses cannot afford to take. Future-proofing your business is about making strategic choices that support continuous adaptation and growth.

This is precisely where Mobile Access to Cloud ERP for Small Manufacturing Managers proves its enduring value. Cloud-based ERP systems are inherently designed for scalability and flexibility, allowing them to adapt to your business’s changing needs without disruptive upgrades. As your business grows, you can easily add more users, modules, or functionalities, paying only for what you use. Furthermore, leading Cloud ERP providers regularly update their software, incorporating the latest technological advancements and security patches automatically. This means your manufacturing business always has access to cutting-edge tools, including potential integrations with AI-driven analytics, IoT sensor data from the shop floor, or advanced automation features. By choosing a cloud-based mobile ERP, small manufacturers effectively future-proof their operations, ensuring they remain competitive and ready to leverage tomorrow’s innovations today.

Overcoming Connectivity Challenges: Strategies for Remote Access

While the benefits of Mobile Access to Cloud ERP for Small Manufacturing Managers are undeniable, concerns about connectivity, especially in areas with unreliable internet or on the shop floor where Wi-Fi might be spotty, can sometimes arise. The effectiveness of a mobile solution hinges on consistent access to data, and a manager might worry about what happens when that connection is lost. Addressing these potential connectivity challenges is crucial for ensuring uninterrupted productivity and maximum utility of the mobile ERP system.

Fortunately, modern Cloud ERP solutions have evolved to include robust strategies for overcoming connectivity hurdles. Many mobile ERP applications offer offline capabilities, allowing users to access, input, and modify data even when there’s no internet connection. Once a connection is re-established, the system automatically synchronizes the changes, ensuring data consistency. Additionally, small manufacturers can invest in reliable Wi-Fi infrastructure on the shop floor, utilize cellular data plans for field personnel, and leverage satellite internet for more remote locations. Some solutions even offer “lite” versions of their mobile apps that require less bandwidth. By strategically implementing these measures, small manufacturing managers can ensure that their teams remain productive and connected, regardless of their location or the stability of their internet access, maximizing the benefits of their mobile ERP investment.

Empowering Your Workforce: The Human Element of Mobile ERP

While we’ve focused heavily on the technological and operational advantages, it’s crucial not to overlook the human element. Mobile Access to Cloud ERP for Small Manufacturing Managers isn’t just about streamlining processes; it’s also about empowering the workforce. Employees at all levels, from shop floor operators to sales representatives, benefit from having immediate access to the information they need to perform their jobs effectively. This empowerment can significantly boost morale, job satisfaction, and overall productivity, creating a more engaged and efficient team.

Think about a shop floor worker who no longer needs to walk to a central computer to check the next task or report a completed one. With a mobile device, they can instantly view their work queue, access digital blueprints, report production progress, and even flag quality issues in real-time. This reduces wasted time, minimizes errors, and gives them a greater sense of control and responsibility over their work. Similarly, a sales person can provide immediate, accurate answers to customer queries, fostering confidence and trust. By reducing manual, repetitive tasks and providing tools that make work easier and more efficient, mobile ERP helps transform the workforce from mere task-doers to informed, proactive contributors, ultimately leading to a more dynamic and capable small manufacturing operation.

Case Studies and Success Stories: Real-World Applications in Small Manufacturing

While theoretical discussions are valuable, seeing how Mobile Access to Cloud ERP for Small Manufacturing Managers translates into real-world success can be incredibly motivating. Across various industries, small manufacturers are leveraging these systems to overcome specific challenges and achieve remarkable growth. These success stories often highlight how a shift from outdated, manual processes to an integrated, mobile-first approach has unlocked previously unimaginable levels of efficiency and profitability. They demonstrate that the benefits are not just theoretical but tangible and measurable.

Consider a small custom metal fabrication shop that struggled with accurate job costing and delivery times due to fragmented data. By implementing a Cloud ERP with mobile capabilities, their project managers could update material consumption and labor hours directly from the shop floor, giving an accurate, real-time view of job profitability. Sales staff, armed with mobile access, could provide precise lead times to customers, improving satisfaction. Another example might be a niche textile manufacturer that previously relied on spreadsheets for inventory, leading to frequent stockouts of specific threads. With mobile ERP, their warehouse staff could scan new deliveries and outgoing orders, ensuring real-time inventory accuracy and automated reorder points, virtually eliminating stock-related delays. These anecdotal, yet widespread, successes underscore the transformative power of mobile-enabled Cloud ERP for small manufacturing businesses striving for operational excellence and competitive advantage.

Conclusion: The Essential Tool for Modern Small Manufacturing Managers

In conclusion, the modern manufacturing landscape demands agility, precision, and real-time responsiveness. For small manufacturing managers, the journey toward achieving these critical attributes is profoundly enhanced and streamlined by the adoption of Mobile Access to Cloud ERP for Small Manufacturing Managers. This powerful combination is not merely a technological upgrade; it represents a fundamental shift in how small businesses can operate, compete, and grow in an increasingly globalized and digital world. It is the bridge between traditional operational constraints and a future brimming with efficiency and opportunity.

From optimizing intricate inventory movements and meticulously streamlining production schedules to empowering sales teams with on-the-go CRM functionalities and providing instant financial visibility, mobile-enabled Cloud ERP transforms every facet of a small manufacturing enterprise. It addresses core pain points like information silos, delayed decision-making, and resource inefficiencies, replacing them with a unified, transparent, and highly responsive operational framework. While concerns about security and connectivity are natural, robust solutions and best practices ensure that data remains protected and accessible, even in challenging environments. By embracing this technology, small manufacturing managers are not just investing in software; they are investing in the future-proofing of their business, ensuring scalability, fostering workforce empowerment, and ultimately securing a strong competitive advantage in a demanding market. The time to unlock your manufacturing potential is now, with the agility of your operations truly in the palm of your hand.