The world of furniture is in constant motion, evolving with trends, materials, and consumer preferences. Yet, within this dynamic landscape, a specific niche stands out for its unique challenges and incredible potential: custom furniture production. Unlike mass-produced items, bespoke pieces demand meticulous attention to detail, highly individualized processes, and an intimate understanding of client needs. For too long, many custom furniture manufacturers have relied on fragmented systems, manual processes, or generic software ill-suited to their intricate workflows. However, a powerful solution has emerged, promising to transform this landscape: Cloud ERP. This article will explore how Empowering Your Workforce with Cloud ERP for Custom Furniture Production isn’t just a trendy phrase but a fundamental shift towards unparalleled efficiency, adaptability, and growth in a highly specialized industry.

The Unique Demands of Custom Furniture and the Promise of Cloud ERP

Custom furniture production is an art and a science, blending creative design with precise engineering and craftsmanship. From the initial client consultation to the final installation, every step is a bespoke journey. Imagine a customer requesting a unique dining table crafted from reclaimed timber with specific dimensions, an unusual finish, and integrated smart features. This isn’t just about selecting an item from a catalog; it’s about translating a vision into a tangible product. This inherent customizability presents a myriad of challenges: managing diverse material inventories, tracking individual project progress, coordinating specialized labor, and ensuring seamless communication across all stakeholders.

Traditionally, these complexities have often led to bottlenecks, errors, and inefficiencies. Spreadsheets can only stretch so far, and disconnected software solutions create data silos, making it difficult to get a holistic view of operations. This is where the promise of Cloud ERP enters the picture. It offers a centralized, integrated platform designed to handle the intricate dance of custom orders, from initial design specifications and material sourcing to manufacturing and delivery. By providing real-time data and automated processes, Cloud ERP doesn’t just manage tasks; it fundamentally transforms how custom furniture businesses operate, paving the way for empowered teams and delighted customers.

Understanding the “Custom” in Custom Furniture Production: Beyond Mass Manufacturing

To truly appreciate the transformative power of Cloud ERP, it’s essential to grasp the fundamental differences between custom and mass-produced furniture. Mass manufacturing thrives on standardization, repetition, and economies of scale. Products are designed once, and then thousands, if not millions, are churned out with identical specifications. The focus is on minimizing unit cost through uniformity and high-volume output. Every component, every process, is optimized for maximum throughput of an identical item.

Custom furniture, by its very definition, defies this model. Each piece is often a one-off or part of a limited series, tailored to specific client requirements, spatial constraints, or aesthetic preferences. This means fluctuating bills of material, unique production routes, variable lead times, and an emphasis on craftsmanship over pure speed. Consider the difference between assembling a flat-pack wardrobe and hand-carving an intricate wooden headboard to a client’s exact design. The “custom” aspect permeates every facet of the business, from sales and design to procurement, production, and even after-sales service. It’s a challenge that demands a flexible, intelligent, and integrated system capable of adapting to constant variation, which is precisely what Cloud ERP provides for Empowering Your Workforce with Cloud ERP for Custom Furniture Production.

Why Traditional Systems Fall Short: The Growing Pains of Bespoke Furniture Makers

For many years, bespoke furniture makers have navigated their complex operations using a patchwork of tools and methods. These often include a combination of manual ledgers, isolated spreadsheets for inventory, basic accounting software, standalone CAD/CAM programs, and a good old-fashioned whiteboard in the workshop. While these tools might serve individual functions adequately, their lack of integration creates significant “growing pains” as a business expands or takes on more intricate projects.

The most critical shortfall lies in the absence of a single source of truth. Data is scattered, inconsistent, and often outdated. A sales team might quote a lead time based on assumed material availability, only for the procurement department to discover that a crucial exotic wood is out of stock. Production schedules become fluid and chaotic, subject to manual adjustments and last-minute changes that ripple through the entire operation. This fragmentation leads to increased administrative overhead, duplicated data entry, higher error rates, delayed production, and ultimately, frustrated customers. Without an integrated solution like Cloud ERP, the potential for truly Empowering Your Workforce with Cloud ERP for Custom Furniture Production remains largely untapped, leaving teams to wrestle with information silos rather than focusing on their craft.

The Rise of Cloud ERP: A Paradigm Shift for Modern Businesses

The landscape of enterprise software has undergone a profound transformation with the advent and widespread adoption of Cloud ERP (Enterprise Resource Planning). Moving away from traditional on-premise installations, where software resided on a company’s own servers, Cloud ERP solutions are hosted by a third-party provider and accessed via the internet. This fundamental shift offers a multitude of benefits that resonate across all industries, including the specialized realm of custom furniture manufacturing.

Cloud ERP brings unparalleled accessibility, allowing authorized users to access critical business data and applications from anywhere, at any time, on any device with an internet connection. This agility is a game-changer for distributed teams or for managers who need to check production statuses while off-site. Furthermore, the subscription-based model (SaaS – Software as a Service) eliminates the hefty upfront costs associated with purchasing and maintaining servers, licenses, and IT infrastructure. Instead, businesses pay a predictable monthly or annual fee, turning a large capital expenditure into a more manageable operational expense. Updates and maintenance are handled by the provider, ensuring that the system is always running on the latest, most secure version. This robust, scalable, and cost-effective approach has positioned Cloud ERP as the cornerstone of modern business operations, providing the essential framework for Empowering Your Workforce with Cloud ERP for Custom Furniture Production.

Bringing it Home: How Cloud ERP Directly Addresses Custom Furniture Challenges

Now, let’s connect the dots and see precisely how the overarching benefits of Cloud ERP translate into tangible solutions for the specific challenges faced by custom furniture manufacturers. The bespoke nature of the industry demands flexibility, precision, and tight coordination – qualities that Cloud ERP is uniquely equipped to deliver. Consider the complexity of managing a diverse range of raw materials, from exotic hardwoods and veneers to specialized upholstery fabrics, hardware, and finishes, all varying by project. A Cloud ERP system can centralize all this inventory data, linking it directly to project bills of material, purchase orders, and production schedules.

Moreover, the typical custom furniture journey involves multiple stakeholders: designers, sales teams, project managers, procurement specialists, workshop artisans, and logistics personnel. Cloud ERP acts as the unifying thread, integrating data and workflows across these departments. From the moment a sales inquiry is logged, through the detailed design phase, material procurement, workshop scheduling, quality control, and final delivery, every piece of information resides in a single, accessible platform. This ensures that everyone is working from the same, most current data, drastically reducing miscommunications and errors. It effectively creates a transparent ecosystem where the entire organization can collaborate seamlessly, truly Empowering Your Workforce with Cloud ERP for Custom Furniture Production by giving them the right tools and information at their fingertips.

Real-Time Data and Enhanced Decision-Making in Custom Workshops

One of the most profound advantages that Cloud ERP brings to the custom furniture sector is the ability to access and analyze real-time data. In an industry where lead times are critical and material costs can fluctuate, having up-to-the-minute information is not just beneficial; it’s essential for survival and growth. Imagine a scenario where a client makes a last-minute design change to a custom cabinet. Without an integrated system, this change could trigger a cascade of manual updates across different spreadsheets and departments: adjusting the bill of materials, re-calculating costs, checking inventory for new components, and rescheduling production. Each manual step introduces a delay and a risk of error.

With Cloud ERP, this process is dramatically streamlined. A change in the design module can instantly update the associated bill of materials, trigger inventory checks, re-calculate project costs and profitability, and even flag potential production conflicts. Workshop managers can view current order backlogs, track the progress of each piece on the shop floor, and identify bottlenecks before they impact delivery schedules. Sales teams can provide accurate lead times and quotes because they have immediate visibility into material availability and production capacity. This enhanced data visibility empowers everyone, from the artisan on the floor to the CEO, to make informed decisions quickly, fostering agility and responsiveness critical for Empowering Your Workforce with Cloud ERP for Custom Furniture Production. This eliminates guesswork, replacing it with actionable insights derived from precise, current operational data.

Streamlining the Design-to-Production Workflow for Unique Pieces

The journey from a client’s initial idea to a finished custom furniture piece is often complex, involving numerous iterations and handoffs between design and production. This critical “design-to-production” workflow is where many custom furniture manufacturers encounter significant friction and inefficiencies. Designers might use specialized CAD software, but the output often needs to be manually translated into production instructions, cutting lists, and routing information for the workshop. This manual translation is a prime source of errors, misinterpretations, and delays.

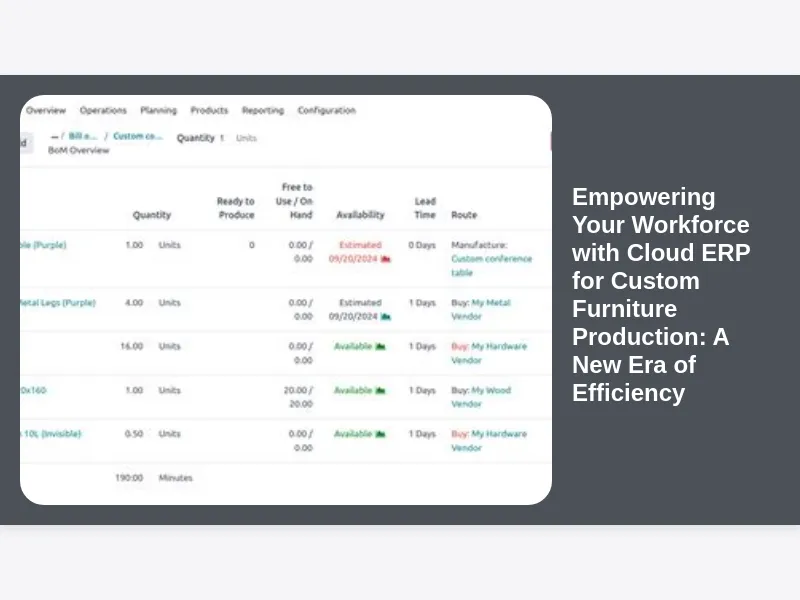

Cloud ERP systems designed for manufacturing, particularly those with modular capabilities, can bridge this gap beautifully. Many modern ERP solutions offer integrations with popular CAD/CAM software, allowing design specifications to flow directly into the ERP system. This means that a completed design can automatically generate a detailed bill of materials (BOM), routing instructions, and labor estimates within the ERP. The system can then automatically trigger material requisition, schedule production tasks, and even generate CNC machine code where applicable. This seamless flow of information ensures that what is designed is precisely what is produced, minimizing rework and maximizing efficiency. By automating these transitions and providing a clear, digital roadmap from concept to creation, Cloud ERP becomes instrumental in Empowering Your Workforce with Cloud ERP for Custom Furniture Production, ensuring consistency and precision even with the most unique designs.

Revolutionizing Inventory Management for Diverse Materials and Components

Managing inventory in a custom furniture production environment is a masterclass in complexity. Unlike industries that deal with a few standardized components, custom furniture often requires a vast array of unique and varied materials. Think of the different species of wood, veneers, laminates, fabrics, leathers, hardware (hinges, pulls, slides), fasteners, glues, stains, and finishes, each with its own supplier, lead time, and storage requirements. Furthermore, specific projects might demand rare or custom-ordered components that need to be tracked individually to ensure they are allocated correctly.

A robust Cloud ERP system can revolutionize this aspect of the business by providing sophisticated inventory management capabilities. It allows for detailed tracking of every item, from raw materials to work-in-progress and finished goods. Features like multi-location inventory tracking, batch and serial number tracking, and automated reorder points ensure that the right materials are always available when needed, preventing costly production delays. The system can even manage vendor information, pricing agreements, and lead times, simplifying the procurement process. By providing clear visibility into stock levels and movement, Cloud ERP helps reduce excess inventory, minimize waste, and prevent stockouts, directly contributing to cost savings and smoother operations, all while profoundly Empowering Your Workforce with Cloud ERP for Custom Furniture Production to make smarter, faster procurement decisions.

Optimizing Supply Chain and Vendor Relationships in a Custom Environment

The supply chain for custom furniture is inherently more complex and often more fragmented than that of mass production. It frequently involves sourcing specialized materials from niche suppliers, managing bespoke orders, and navigating varying lead times. In this environment, strong vendor relationships and an optimized supply chain are paramount to success. Delays in material delivery or quality issues from a supplier can quickly derail a custom project, impacting customer satisfaction and profitability.

Cloud ERP acts as a central nervous system for the supply chain, consolidating all vendor information, purchase orders, delivery schedules, and historical performance data. This allows custom furniture manufacturers to gain comprehensive visibility into their procurement processes. The system can automate purchase order generation based on production schedules and inventory levels, ensuring timely replenishment of materials. It can also track vendor performance metrics, helping businesses identify reliable suppliers and negotiate better terms. Furthermore, by providing a unified platform for communication and documentation, Cloud ERP fosters stronger relationships with suppliers, leading to improved reliability, better pricing, and a more resilient supply chain overall. This robust management of external relationships is crucial for Empowering Your Workforce with Cloud ERP for Custom Furniture Production to maintain efficiency and flexibility in a demanding market.

Elevating Customer Experience and Order Fulfillment for Bespoke Creations

In the world of custom furniture, the customer experience is everything. Clients aren’t just buying a product; they’re investing in a unique vision, and their expectations for communication, transparency, and quality are exceptionally high. Managing client expectations, providing accurate updates, and ensuring a seamless order fulfillment process can be challenging when dealing with one-of-a-kind creations that have variable production timelines. Manual communication and tracking often lead to missed updates and client anxiety.

Cloud ERP, especially when integrated with CRM (Customer Relationship Management) functionalities, profoundly elevates the customer experience. From the initial inquiry, sales teams can leverage the ERP to quickly generate accurate quotes based on real-time material costs and production capacity. Once an order is placed, clients can be provided with a portal or regular automated updates detailing their project’s progress, from design approval to materials sourcing, production milestones, and estimated delivery. The system tracks every aspect of the order, ensuring that all customizations are meticulously followed. This level of transparency and proactive communication builds trust and confidence. Furthermore, by streamlining the entire fulfillment process, from final quality checks to packaging and delivery logistics, Cloud ERP ensures that bespoke creations arrive on time and as promised, significantly boosting customer satisfaction and loyalty, which is key to Empowering Your Workforce with Cloud ERP for Custom Furniture Production to deliver exceptional service.

Empowering Your Production Workforce with Intuitive Tools and Information

While Cloud ERP offers strategic benefits for management, its true power in a custom furniture setting lies in how it empowers the production workforce on the shop floor. Artisans and craftspeople are the heart of a custom furniture business, and providing them with the right tools and information can dramatically increase their efficiency, accuracy, and job satisfaction. Often, skilled workers spend valuable time searching for blueprints, confirming material specifications, or trying to decipher ambiguous production orders. This administrative burden detracts from their core craft.

A well-implemented Cloud ERP system can deliver precise, up-to-date production orders directly to the workshop floor, often through tablets or dedicated workstations. Each work order can include detailed specifications, CAD drawings, material lists, process instructions, and quality checkpoints. Workers can easily log their progress, report issues, and access relevant documentation with a few taps. This minimizes errors, reduces idle time, and ensures that everyone is working from the latest version of truth. Furthermore, by automating mundane administrative tasks, Cloud ERP frees up artisans to focus on their skilled craft, enhancing productivity and quality. This direct access to relevant, real-time information is central to Empowering Your Workforce with Cloud ERP for Custom Furniture Production, transforming them from manual labor into informed, efficient contributors.

Financial Visibility and Strategic Planning for Scaling Custom Furniture Businesses

For custom furniture businesses aiming for sustainable growth, robust financial visibility and strategic planning are indispensable. Without accurate, up-to-date financial data, making informed decisions about pricing, expansion, and investment becomes a perilous guessing game. Many custom workshops struggle with profitability analysis on a per-project basis, often underestimating true costs or failing to account for overheads adequately. This lack of clear financial insight can hinder growth and even threaten the long-term viability of the business.

Cloud ERP integrates financial management modules directly with all operational data. Every purchase, every labor hour logged, every material used, and every sale processed flows directly into the accounting system. This provides a granular view of costs associated with each custom project, allowing for precise profitability analysis. Businesses can track expenses, manage budgets, process invoices, and generate comprehensive financial reports in real time. Beyond basic accounting, Cloud ERP offers powerful analytics and business intelligence tools. These enable management to identify trends, forecast future demand, optimize pricing strategies, and make data-driven decisions regarding resource allocation and expansion. Such comprehensive financial oversight is a critical component for Empowering Your Workforce with Cloud ERP for Custom Furniture Production not just at the operational level, but at the strategic and executive level too. It ensures that growth is not just achieved, but sustained and profitable.

Overcoming Implementation Hurdles: A Smooth Transition to Cloud ERP for Furniture Manufacturers

While the benefits of Cloud ERP are compelling, the thought of implementing such a comprehensive system can seem daunting, especially for businesses that have long relied on traditional methods. Concerns about data migration, user training, potential disruptions to operations, and the overall cost are valid. However, with careful planning and the right approach, these hurdles can be effectively managed, ensuring a smooth transition to Cloud ERP for furniture manufacturers. The key lies in strategic planning and phased implementation.

The first step is a thorough needs assessment to identify specific pain points and desired outcomes. Choosing an ERP provider with experience in manufacturing, and ideally custom manufacturing, is crucial. Data migration, though complex, can be managed with structured processes and often supported by the ERP vendor. User training is paramount; investing time in teaching the workforce how to effectively use the new system, highlighting its benefits, and addressing their concerns will foster adoption. Often, a phased rollout—implementing one module at a time or starting with a smaller pilot project—can minimize disruption and allow the team to adjust gradually. Furthermore, the accessibility of cloud-based training resources and ongoing vendor support makes the learning curve far less steep than with traditional on-premise systems. By addressing these common concerns proactively, businesses can unlock the full potential of Empowering Your Workforce with Cloud ERP for Custom Furniture Production without unnecessary stress or delay.

The Future of Custom Furniture: Innovation Driven by Digital Transformation

The custom furniture industry stands on the precipice of a new era, one where traditional craftsmanship is seamlessly augmented by advanced digital tools. The future of custom furniture production is not about replacing human skill but about enhancing it, making it more efficient, more precise, and more responsive to client demands. This digital transformation, spearheaded by solutions like Cloud ERP, is not just about catching up; it’s about leading the way in innovation.

Imagine a future where AI-driven analytics within the ERP system can predict material price fluctuations, allowing for proactive procurement. Or where virtual reality tools, integrated with the ERP, allow clients to visualize their bespoke furniture in their own space before a single cut is made, with all design changes automatically updating the production schedule. The integration of IoT (Internet of Things) devices on the shop floor could feed real-time machine performance data directly into the ERP, optimizing maintenance schedules and identifying bottlenecks. Cloud ERP serves as the foundational platform upon which these future innovations will be built, enabling custom furniture manufacturers to not only meet evolving customer expectations but to proactively shape them. By embracing this digital evolution, businesses are truly Empowering Your Workforce with Cloud ERP for Custom Furniture Production, ensuring their legacy of craftsmanship thrives in a technologically advanced world. This journey towards enhanced efficiency, reduced errors, and greater profitability ensures that custom furniture remains a vibrant, sought-after segment of the market for generations to come.