Small manufacturing businesses operate in a fiercely competitive landscape, where every efficiency gain, every cost saving, and every decision about production can significantly impact the bottom line. Among the myriad challenges these businesses face, effectively managing raw materials inventory stands out as a critical yet often overlooked area. Mismanaging raw materials can lead to disastrous consequences, from production delays and stockouts that halt operations to excessive holding costs from overstocking, tying up valuable capital. Imagine a scenario where a sudden surge in orders can’t be met because a crucial component is missing, or conversely, shelves are overflowing with materials that won’t be used for months, draining cash flow. This is where the power of Enterprise Resource Planning (ERP) truly shines, offering a transformative solution specifically tailored to the unique needs of small manufacturing enterprises. By integrating various operational facets, an ERP system empowers these businesses to achieve what once seemed impossible: managing raw materials inventory not just efficiently, but seamlessly.

The journey to seamless inventory management is not merely about tracking items; it’s about gaining unparalleled visibility, optimizing processes, and making data-driven decisions that propel your small manufacturing operation forward. For many small manufacturers, the idea of implementing a sophisticated ERP system might seem daunting, perhaps perceived as an expensive luxury reserved for larger corporations. However, modern ERP solutions are increasingly scalable, user-friendly, and cost-effective, making them an accessible and indispensable tool for businesses of all sizes, especially those looking to grow. This comprehensive article will delve into how an ERP for small manufacturing specifically addresses the complexities of raw materials inventory, offering practical insights and demonstrating the profound impact it can have on your operational efficiency, profitability, and overall competitiveness. Get ready to discover how to turn your inventory management from a persistent headache into a strategic advantage, ensuring your production lines always have what they need, exactly when they need it.

The Unique Inventory Challenges Faced by Small Manufacturers

Small manufacturing businesses, despite their agility and often niche focus, frequently grapple with a unique set of inventory challenges that can severely hinder their growth and profitability. Unlike larger corporations with dedicated logistics teams and sophisticated legacy systems, small manufacturers often rely on rudimentary methods, which while seemingly cost-effective in the short term, breed inefficiencies and errors. Picture a bustling workshop where inventory counts are performed manually, often using spreadsheets or even pen and paper. This approach is not only incredibly time-consuming but also highly susceptible to human error, leading to inaccurate stock levels that can throw an entire production schedule into disarray. A miscount of a critical raw material might not be discovered until it’s too late, triggering an urgent, expensive rush order that cuts into profit margins and delays customer delivery.

The lack of real-time visibility is another significant hurdle. Without an integrated system, it’s difficult for different departments – from purchasing to production to sales – to have a unified, up-to-the-minute understanding of what raw materials are on hand, what’s in transit, and what’s committed to current orders. This siloed information often results in poor communication, missed opportunities, and reactive rather than proactive decision-making. Moreover, small manufacturers often face fluctuating demand, making accurate forecasting a monumental task without historical data analysis capabilities. This leads to either debilitating stockouts, where production grinds to a halt and customer orders are delayed, or costly overstocking, tying up precious working capital in dormant raw materials that occupy valuable warehouse space and are at risk of obsolescence or damage. These challenges, if left unaddressed, create a perpetual cycle of inefficiencies that prevent small manufacturing businesses from reaching their full potential.

Understanding ERP: More Than Just Software for Small Manufacturing

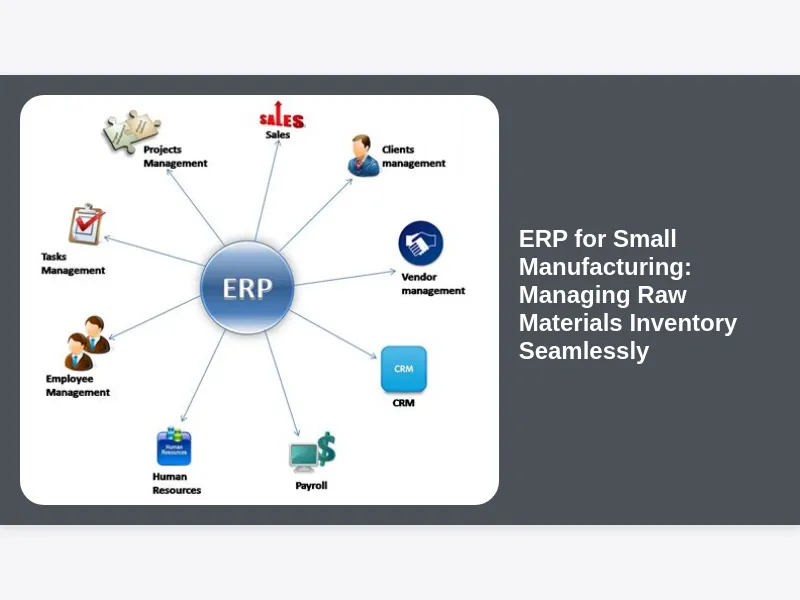

Before we dive deep into how an ERP system revolutionizes raw materials inventory, it’s essential to understand what ERP truly is, especially in the context of small manufacturing. Enterprise Resource Planning (ERP) is far more than just a piece of software; it’s an integrated suite of business applications designed to manage and connect all core aspects of an enterprise. Think of it as the central nervous system for your entire manufacturing operation, linking together departments that traditionally operate in isolation. From finance and human resources to sales, production, supply chain, and of course, inventory management, ERP provides a unified platform where all data resides and flows seamlessly. This holistic approach eliminates data silos, ensures consistency, and provides a single source of truth for all business operations.

For a small manufacturing business, this integration is particularly powerful. Instead of using separate software for accounting, another for production scheduling, and yet another for tracking inventory, an ERP system consolidates these functions. This means that when a sales order is placed, the ERP can instantly check raw material availability, schedule production, update financial records, and even trigger a reorder if stock levels are low – all automatically and in real-time. This interconnectedness allows for unprecedented operational transparency and efficiency, moving beyond the fragmented processes that often plague smaller operations. Modern ERP for small manufacturing solutions are designed with modularity in mind, meaning businesses can start with essential modules like inventory and production, and then expand as their needs evolve, making it a scalable investment rather than an all-or-nothing proposition. It transforms discrete processes into a fluid, interconnected workflow, providing the foundation for growth and competitiveness.

Why Raw Materials Inventory is Critical for Small Manufacturing Success

The significance of raw materials inventory in a small manufacturing context cannot be overstated; it forms the very bedrock of the production process and directly influences a company’s financial health and market reputation. Consider your raw materials not just as physical items, but as the lifeblood of your operation. Without them, or with the wrong quantities, your production line ceases to function, leading to costly idle time for machinery and employees. This directly impacts your ability to fulfill orders, meet customer deadlines, and ultimately, generate revenue. Imagine a scenario where a crucial component for a product, perhaps a specialized metal alloy or an electronic circuit, is out of stock. The entire batch of products cannot be completed, leading to missed delivery dates and potentially lost customers, who might then turn to a competitor.

Beyond mere availability, the management of raw materials inventory also has a profound effect on a small manufacturer’s cash flow and profitability. Overstocking, while it might seem safe, ties up a significant amount of capital that could otherwise be invested in growth initiatives, marketing, or research and development. This capital becomes stagnant, incurring storage costs, insurance fees, and risking obsolescence, especially if product designs change or demand shifts. Conversely, understocking leads to emergency purchases, often at higher prices due to expedited shipping and lack of negotiation power, eroding profit margins. Moreover, consistent inventory issues tarnish a company’s reputation, making it unreliable in the eyes of customers and potentially straining relationships with suppliers. Efficient management of raw materials, therefore, isn’t just an operational detail; it’s a strategic imperative that directly contributes to consistent production, healthy cash flow, customer satisfaction, and the sustained success of any small manufacturing enterprise.

The Core of Seamless Management: How ERP Transforms Raw Materials Tracking

At the heart of achieving truly seamless raw materials inventory management for a small manufacturing business lies the transformative power of an ERP system. Gone are the days of manual spreadsheets, fragmented data, and educated guesses. An ERP for small manufacturing fundamentally redefines how raw materials are tracked by providing real-time visibility and automating critical processes, turning what was once a chaotic endeavor into a precise, predictable operation. When raw materials arrive at your facility, an ERP system can instantly record their receipt, assign them to specific bins or locations, and update overall stock levels across all relevant modules. This means that as soon as materials enter your door, every department has an accurate, up-to-the-minute understanding of their availability.

This real-time tracking extends throughout the entire lifecycle of the raw material. As production orders consume materials, the ERP automatically deducts them from inventory. If materials are transferred between warehouses or production lines, the system updates their location instantly. This continuous, dynamic update mechanism eliminates discrepancies and ensures that the reported stock levels always reflect the physical reality. Furthermore, an ERP can be configured with minimum and maximum stock levels, triggering automated reorder alerts or even generating purchase orders directly to approved suppliers when thresholds are met. This proactive approach prevents stockouts before they occur, reducing emergency purchases and ensuring a smooth flow of materials to the production floor. By centralizing all inventory data and automating these crucial tracking functions, ERP systems effectively remove the guesswork and manual errors that plague traditional methods, paving the way for truly seamless management of your raw materials.

Beyond Basics: Advanced Inventory Features in ERP for Small Manufacturers

While real-time tracking is a cornerstone, modern ERP for small manufacturing systems offer a wealth of advanced inventory features that elevate raw material management beyond mere quantity counts. These sophisticated capabilities are designed to address the specific complexities that small manufacturers often face, providing granular control and enhanced traceability. One crucial feature is lot tracking or batch management. For industries dealing with regulated products, perishable goods, or components with varying quality or expiration dates, lot tracking allows you to track specific batches of raw materials from their receipt through production and even to the final product. This means that if a quality issue arises with a particular batch, you can quickly identify all products that used those materials, enabling swift recalls or targeted investigations, minimizing risk and ensuring compliance.

Similarly, serial number tracking provides even finer detail, assigning a unique identifier to individual items. While perhaps less common for bulk raw materials, it’s invaluable for high-value components or sub-assemblies where individual identification is critical. ERP systems also support multiple warehouse or location management, allowing you to track raw materials across different storage facilities, production areas, or even consignment locations with precision. This is particularly useful for small manufacturers with growing operations or distributed supply chains. Furthermore, advanced inventory valuation methods like FIFO (First-In, First-Out), LIFO (Last-In, First-Out), or weighted average costing can be automatically applied, providing accurate cost accounting for your raw materials. These features, integrated within a single ERP platform, offer small manufacturers the kind of sophisticated control over their raw materials inventory that was once only available to much larger enterprises, enabling smarter decision-making and significantly reducing operational risks.

Boosting Production Efficiency with Integrated ERP Planning

For small manufacturers, the direct link between raw materials inventory and production efficiency is undeniable. Any hiccup in material availability translates instantly into production delays, idle machinery, and wasted labor hours. This is precisely where an ERP for small manufacturing system proves invaluable, acting as a crucial bridge between your raw materials and your production planning. By integrating inventory data directly with the production scheduling module, ERP ensures that production plans are always based on accurate, up-to-the-minute information regarding material availability. Imagine a scenario where a production order is generated; the ERP system can immediately check if all required raw materials are in stock. If they are not, it can flag the issue, suggest alternative materials, or even adjust the production schedule to align with material arrival dates, all before any physical work begins.

This proactive approach prevents bottlenecks and minimizes costly stoppages on the production floor. The ERP system can automatically generate a Bill of Materials (BOM) for each product, outlining all necessary raw materials and their quantities. When a production run is initiated, the system reserves these materials, preventing them from being allocated to other orders inadvertently. Furthermore, advanced ERP systems incorporate Material Requirements Planning (MRP) functionality, which takes sales forecasts, existing orders, and current inventory levels into account to calculate precisely what raw materials are needed, and exactly when they are needed, to meet future production demands. This “pull” system minimizes overstocking and ensures a lean, efficient production flow. By providing this integrated view and automated planning capabilities, ERP transforms production scheduling from a reactive, often chaotic process into a streamlined, highly efficient operation, directly translating to higher output and faster order fulfillment for small manufacturers.

Strategic Purchasing and Supplier Relationship Management through ERP

Effective raw materials inventory management extends far beyond simply tracking items; it fundamentally involves strategic purchasing and robust supplier relationship management. For small manufacturing businesses, securing the right materials at the right price and at the right time is paramount, and an ERP for small manufacturing significantly elevates capabilities in this critical area. The ERP system, with its comprehensive view of inventory levels, production schedules, and sales forecasts, can automatically generate purchase requisitions for raw materials well in advance of actual need. This transition from reactive, emergency buying to proactive, planned procurement empowers purchasing managers to negotiate better terms, secure volume discounts, and reduce expedited shipping costs.

Beyond just purchase order generation, an ERP system can serve as a central repository for all supplier information, including contact details, pricing agreements, lead times, historical performance data, and quality ratings. This wealth of information allows small manufacturers to make informed decisions about which suppliers to use, fostering stronger, more reliable relationships. The system can track supplier delivery performance against agreed-upon schedules, helping to identify unreliable vendors and mitigate supply chain risks before they impact production. Furthermore, by consolidating purchasing data, ERP provides insights into spending patterns, enabling businesses to identify opportunities for cost savings, consolidate orders, and optimize their supplier base. This strategic approach to purchasing and supplier management, facilitated by ERP, ensures a consistent and cost-effective supply of raw materials, strengthening the entire supply chain for the small manufacturer.

Data Accuracy and Reporting: The Foundation of Informed Decisions in Small Manufacturing

In the fast-paced world of manufacturing, decisions made on inaccurate or outdated information can be incredibly costly. For small manufacturers, especially when it comes to raw materials inventory, reliable data is not a luxury but a fundamental necessity. This is precisely where an ERP for small manufacturing system excels, establishing a single, trusted source of truth that underpins all operational and strategic decisions. By centralizing all inventory transactions – from goods receipt and material consumption to transfers and adjustments – an ERP system inherently drives data accuracy. Manual entry errors are drastically reduced, and inconsistencies between different departmental records are eliminated, as everyone is working from the same live data set.

The benefits of this data accuracy are amplified through the powerful reporting capabilities inherent in ERP systems. Small manufacturing businesses can generate a wide array of reports, customized to their specific needs, providing deep insights into their raw materials inventory. These reports can show current stock levels, historical usage trends, inventory turnover rates, obsolescence risk, and even the financial value of inventory on hand. Imagine being able to quickly pull a report detailing which raw materials are moving slowly, allowing you to proactively adjust purchasing or sales strategies to clear stagnant stock. Or, conversely, identifying consistently fast-moving items to ensure optimal safety stock levels. This ability to access and analyze precise data empowers management to make informed decisions, optimize inventory levels, identify cost-saving opportunities, and ultimately, steer the business towards greater profitability and sustained growth, transforming raw material data from a chore into a strategic asset.

Forecasting Demand with Precision: Minimizing Waste and Maximizing Profit

For small manufacturing businesses, accurately forecasting demand for finished goods directly impacts the need for raw materials, making it a critical element in achieving efficient inventory management. Without a reliable forecasting mechanism, businesses are left to guess, leading either to overstocking (tying up capital and incurring holding costs) or understocking (resulting in lost sales and production delays). This is where an ERP for small manufacturing system becomes an indispensable tool, leveraging historical data and analytical capabilities to provide a much clearer picture of future needs. Unlike manual methods that often rely on gut feeling or limited data, an ERP system can analyze vast amounts of historical sales data, seasonal trends, and even external market factors to generate more accurate demand forecasts.

By integrating sales orders, historical sales records, and even marketing promotions, the ERP system can predict future demand for products. This predicted demand is then translated into raw material requirements through the Bill of Materials (BOM) module, giving manufacturers a proactive view of what materials they will need and when. This allows purchasing managers to plan orders strategically, capitalizing on bulk discounts, securing favorable pricing, and ensuring materials arrive just in time for production, minimizing storage costs. Furthermore, the ability to run “what-if” scenarios within the ERP allows businesses to model the impact of different demand fluctuations, helping them build more resilient inventory strategies. This precision in demand forecasting, enabled by ERP, empowers small manufacturers to minimize waste by reducing obsolete inventory, maximize profit by optimizing purchasing, and maintain consistent production schedules, keeping their operations lean and responsive to market changes.

Cost Reduction and Cash Flow Optimization with an ERP System

The financial benefits of implementing an ERP for small manufacturing system, particularly in the realm of raw materials inventory, are substantial and directly impact a company’s profitability and cash flow. For many small manufacturers, raw materials represent a significant portion of their operating expenses, and inefficient management in this area can quickly erode margins. An ERP system directly addresses this by optimizing inventory levels, reducing waste, and streamlining procurement, all of which translate into tangible cost savings. By providing real-time visibility and accurate forecasting, ERP helps eliminate overstocking, which significantly reduces carrying costs associated with storage space, insurance, obsolescence, and potential damage. Imagine the money saved when you no longer have excess inventory sitting idle for months, slowly depreciating in value.

Furthermore, the ability to plan purchases strategically, leverage historical data for negotiations, and track supplier performance through ERP leads to more favorable pricing and terms for raw materials. The reduction in emergency, rush orders – often incurred at a premium price – directly contributes to cost savings. By minimizing stockouts, ERP prevents costly production stoppages, which involve idle labor, wasted machine time, and the financial penalties of late deliveries. The efficiency gains extend to reduced administrative costs as well; automating tasks like data entry, purchase order generation, and invoice matching frees up valuable staff time that can be redirected to more strategic activities. All these factors collectively contribute to a healthier bottom line and improved cash flow. By ensuring that capital is not tied up in excess or obsolete inventory, and by optimizing the entire raw material supply chain, an ERP system empowers small manufacturers to operate more profitably and with greater financial agility, ensuring resources are available for growth and innovation.

Selecting the Right ERP for Your Small Manufacturing Business

Choosing the right ERP for small manufacturing is a pivotal decision that can shape the future trajectory of your business. It’s not a one-size-fits-all proposition; what works for a large enterprise may not be suitable or cost-effective for a small, specialized manufacturer. The selection process requires careful consideration of several key factors to ensure the system genuinely meets your unique needs and supports your growth ambitions. First and foremost, consider industry-specific functionality. Does the ERP solution have modules or features specifically designed for your type of manufacturing, such as discrete, process, or mixed-mode manufacturing? This can include specialized features for bill of materials (BOM) management, shop floor control, quality management, or even compliance requirements specific to your sector. A generic ERP might offer basic inventory tracking, but an industry-tailored solution will provide the depth of functionality required for seamless raw materials management and beyond.

Scalability is another critical consideration. Your business is likely to grow, and your ERP system should be able to grow with it without requiring a complete overhaul in a few years. Look for solutions that offer modularity, allowing you to add more users, functionalities, or integrate with other systems as your business expands. Ease of use and user interface (UI) are also paramount; a complex, unintuitive system will lead to low user adoption and wasted investment. Seek out a system that offers a clean, user-friendly interface and robust training resources. Finally, assess the total cost of ownership, which includes not just the software license or subscription fees, but also implementation costs, training, ongoing support, and potential customization expenses. Look for a vendor with a strong track record, reliable customer support, and a clear pricing structure that aligns with your budget and long-term financial planning. By meticulously evaluating these factors, small manufacturers can confidently select an ERP system that will serve as a true enabler of efficiency and growth.

Navigating the ERP Implementation Journey for Small Manufacturers

Implementing an ERP for small manufacturing system, while promising immense benefits, is a significant undertaking that requires careful planning and execution. It’s not simply installing software; it’s a fundamental transformation of your business processes. Approaching the implementation journey with a structured plan is crucial to minimize disruption and ensure a successful rollout. The first step involves a thorough business process analysis. Before even looking at software, clearly define your current workflows, identify pain points, and outline your desired future state. This clarity will guide the configuration of the ERP system and ensure it aligns with your specific operational needs, particularly concerning raw materials inventory management. What are your current inventory tracking methods? What data do you need to capture? Who needs access to what information? Answering these questions upfront is vital.

Next comes data migration. This is often the most challenging part, especially for businesses moving away from fragmented systems or manual records. Accurate and clean historical data for raw materials, supplier information, and production records must be meticulously transferred into the new ERP system. This may involve extensive data cleansing and formatting. Subsequently, the system configuration and customization phase tailors the ERP to your unique business rules and workflows. This is where you set up inventory locations, define raw material attributes, configure reorder points, and integrate with existing machinery if applicable. Finally, rigorous testing of the system – from individual modules to end-to-end processes – is essential before going live. Involve key users in testing to ensure the system functions as expected and meets operational requirements. A phased approach, starting with critical modules like raw materials inventory, can also help small manufacturers manage the transition more effectively, allowing for adjustments and learning before a full enterprise-wide rollout.

Training, Support, and User Adoption: Ensuring ERP Success

The most sophisticated ERP for small manufacturing system will fail to deliver its promised benefits if employees are unwilling or unable to use it effectively. Therefore, comprehensive training, ongoing support, and a focus on user adoption are absolutely critical for a successful ERP implementation. It’s a common misconception that once the software is installed, the job is done; in reality, this is just the beginning. Employees across all departments – from warehouse staff managing raw materials to production managers and procurement specialists – must understand how to navigate the new system, input data correctly, and leverage its features to perform their daily tasks. Effective training goes beyond simply showing them which buttons to click; it explains the ‘why’ behind the new processes, demonstrating how the ERP will make their jobs easier, more efficient, and ultimately, more impactful.

Developing a robust training program that includes both initial sessions and ongoing refreshers is essential. This can involve hands-on workshops, user manuals, video tutorials, and even a dedicated internal champion who can provide peer-to-peer support. Furthermore, access to reliable and responsive technical support from the ERP vendor is paramount. When questions arise or issues surface, prompt assistance can prevent frustration and keep operations running smoothly. Encouraging user adoption also involves fostering a positive attitude towards the change. Communicate the benefits clearly and involve employees in the process where possible, making them feel like contributors rather than passive recipients of a new system. By investing in thorough training, ensuring readily available support, and actively working to overcome resistance to change, small manufacturers can ensure their ERP system becomes an indispensable tool that empowers their workforce and genuinely transforms their raw materials inventory management and overall operations.

Scalability and Future-Proofing Your Operations with ERP

For small manufacturing businesses, the concept of growth is central to their mission. As operations expand, product lines diversify, and customer bases multiply, the demands on an underlying business system increase exponentially. This is where the inherent scalability of an ERP for small manufacturing system becomes a major strategic advantage, effectively future-proofing your operations against the complexities of growth. Unlike standalone software solutions or manual processes that quickly buckle under increased volume and complexity, a well-chosen ERP is designed to evolve with your business. It’s built with the capacity to handle more users, manage a larger volume of transactions, and accommodate additional modules or functionalities as your needs change.

Imagine your business triples its production capacity and opens a second manufacturing facility. A fragmented system would require entirely new installations, data synchronization nightmares, and potentially duplicate efforts. An ERP, however, can seamlessly integrate the new facility, managing raw materials inventory across multiple locations, standardizing processes, and providing a consolidated view of operations from a single platform. As your product portfolio grows, the ERP’s Bill of Materials (BOM) management and production planning capabilities can easily adapt to new designs and variations. If you decide to expand into new markets or face evolving regulatory requirements, the ERP system can often be configured or extended to support new compliance standards, traceability needs, or international accounting principles. This inherent adaptability and capacity for expansion mean that your initial investment in an ERP system continues to pay dividends as your business matures, eliminating the need for costly and disruptive system replacements every few years. It transforms your raw materials inventory management, and indeed your entire business, into a resilient and agile entity prepared for whatever the future holds.

Achieving Compliance and Traceability: Essential for Modern Manufacturing

In today’s intricate manufacturing landscape, especially for small businesses, merely producing goods isn’t enough. Many industries, from food and beverage to medical devices and automotive components, are subject to stringent regulatory requirements regarding product quality, safety, and origin. This makes achieving robust compliance and comprehensive traceability not just good practice, but an absolute necessity. An ERP for small manufacturing system is an indispensable tool in meeting these critical demands, particularly concerning raw materials inventory. Traditional, manual methods often struggle to provide the granular detail required for audits or to quickly identify the source of a quality issue, leaving small manufacturers vulnerable to costly fines, recalls, and reputational damage.

An ERP system, by meticulously tracking every raw material from its receipt to its transformation into a finished product, provides an unbroken chain of custody. Features like lot tracking and serial number management, which we discussed earlier, are paramount here. They allow a manufacturer to record not only what raw material went into which product, but also when it was received, from which supplier, and even which specific batch it belonged to. If a supplier issues a recall for a particular lot of material, the ERP can instantly identify all finished products that incorporated that material, enabling a targeted and efficient response. This level of traceability is invaluable for demonstrating compliance with industry standards (e.g., ISO certifications) and regulatory bodies. Furthermore, ERP systems often include integrated quality management modules that allow for the recording of quality checks, non-conformances, and corrective actions directly linked to specific raw materials or production batches. By providing this detailed audit trail and structured approach to quality, ERP empowers small manufacturers to confidently navigate complex regulatory environments, build trust with customers, and mitigate significant business risks, transforming compliance from a burden into an integral, seamless part of their operations.

Overcoming Common Myths About ERP for Small Businesses

For many small manufacturing businesses, the idea of adopting an ERP system is often accompanied by a host of misconceptions and fears. These common myths often deter them from exploring solutions that could fundamentally transform their operations, especially in areas like raw materials inventory. One of the most pervasive myths is that ERP for small manufacturing is prohibitively expensive, an exorbitant luxury reserved solely for multi-million dollar corporations. While it’s true that large enterprise ERPs can be costly, the market has evolved significantly. Today, there are numerous cloud-based, subscription-model ERP solutions tailored specifically for small and medium-sized businesses (SMBs), offering scalable pricing that makes them accessible and affordable. These solutions reduce the need for large upfront capital expenditures on hardware and IT infrastructure, significantly lowering the barrier to entry.

Another widespread myth is that ERP implementation is excessively complex and disruptive, requiring months or even years of effort that a small business simply cannot afford. While implementation does require planning and commitment, modern ERPs are designed for quicker deployment, especially for smaller businesses with fewer complex processes. Many vendors offer streamlined implementation packages, and cloud ERPs often require less technical expertise on the part of the client. Furthermore, the perception that ERP is too difficult for employees to learn and use is also often unfounded. Contemporary ERP interfaces are increasingly user-friendly and intuitive, mirroring the simplicity of consumer applications. With proper training and support, which we’ve discussed, user adoption can be high. By debunking these myths, small manufacturers can realize that ERP is not an unreachable dream, but a tangible, cost-effective, and manageable solution that can drive significant efficiencies and competitive advantages in managing raw materials and beyond.

The ROI of Investing in ERP for Small Manufacturing

For any small manufacturing business owner, every investment decision ultimately boils down to one crucial question: what is the return on investment (ROI)? While the upfront cost and effort of implementing an ERP for small manufacturing might seem substantial, the long-term financial and operational benefits, particularly in managing raw materials inventory, typically far outweigh the initial outlay. Quantifying the ROI of an ERP system involves looking at both direct cost savings and indirect improvements in efficiency and competitiveness. Directly, an ERP system reduces inventory holding costs by optimizing stock levels and minimizing overstocking, freeing up working capital. It cuts down on emergency procurement costs, often associated with rush orders and expedited shipping. Fewer production stoppages due to raw material shortages mean less idle time for labor and machinery, translating directly into saved wages and increased output.

Indirectly, the value is even more profound. Improved data accuracy and real-time visibility lead to better decision-making, allowing management to react swiftly to market changes and make strategic purchasing decisions. Enhanced traceability and compliance mitigate the risk of costly fines, recalls, and reputational damage. Streamlined processes reduce administrative overhead and eliminate redundant tasks, allowing employees to focus on value-added activities. Better demand forecasting leads to higher customer satisfaction through on-time deliveries, potentially increasing repeat business and market share. While some of these benefits are harder to put a precise dollar figure on, their cumulative impact on a small manufacturer’s profitability, growth potential, and competitive edge is undeniable. Numerous industry studies and success stories demonstrate that small businesses can achieve a positive ROI on their ERP investment within a relatively short period, often within 1-3 years, making it not just an expense, but a strategic investment in sustained success. [Source: SAP, Plex Systems, Aberdeen Group case studies]

The Digital Transformation: Embracing Automation for Competitive Edge

In an increasingly digitized global economy, small manufacturing businesses cannot afford to remain tethered to outdated manual processes. Embracing digital transformation, particularly through the implementation of an ERP for small manufacturing, is no longer an option but a strategic imperative for gaining and maintaining a competitive edge. At the core of this transformation is automation, which revolutionizes how raw materials inventory is managed and integrated into the broader manufacturing ecosystem. Automation within an ERP system moves businesses away from repetitive, error-prone manual tasks, freeing up human capital to focus on more complex problem-solving, innovation, and strategic planning.

Consider the daily grind of manual inventory tasks: counting stock, updating spreadsheets, generating purchase orders by hand, and physically checking locations. Each of these tasks is a potential source of error and inefficiency. An ERP system automates many of these functions: it automatically deducts raw materials as they are consumed in production, triggers reorder alerts based on predefined thresholds, generates purchase orders directly to suppliers, and even reconciles invoices upon material receipt. This level of automation significantly reduces the time and effort spent on administrative tasks, accelerates workflows, and ensures a much higher degree of accuracy in inventory records. Furthermore, the integration of automation extends to the shop floor, potentially connecting with production machinery to track material consumption in real-time. By embracing this digital transformation and leveraging the automation capabilities of an ERP, small manufacturers can streamline their operations, reduce operational costs, enhance responsiveness, and ultimately position themselves as agile, efficient, and highly competitive players in the market, ready to adapt to future challenges and seize new opportunities.

Conclusion: Mastering Your Raw Materials Inventory with ERP for Sustainable Growth

In the dynamic and often unforgiving world of manufacturing, the meticulous management of raw materials inventory is not merely an operational detail; it is a strategic cornerstone for sustained success, especially for small businesses striving for growth. The journey from fragmented, manual processes to a state of seamless inventory control can seem daunting, but as we’ve explored, the solution lies squarely within the capabilities of a modern Enterprise Resource Planning (ERP) system. An ERP for small manufacturing transforms what was once a source of constant headaches and inefficiencies into a powerful engine of productivity, cost savings, and informed decision-making. It eliminates the guesswork, replaces reactive problem-solving with proactive planning, and fosters an environment of unparalleled transparency and accuracy across your entire operation.

From providing real-time visibility into every component to automating purchase orders and streamlining production schedules, an ERP system ensures that your raw materials are always precisely where they need to be, exactly when they’re needed. It liberates capital tied up in excess stock, significantly reduces the risk of costly production delays due to shortages, and empowers you to build stronger, more reliable relationships with your suppliers. Beyond the immediate operational benefits, an ERP future-proofs your small manufacturing business, offering the scalability to grow without outgrowing your systems and the robust traceability necessary to meet increasingly stringent compliance demands. By embracing this transformative technology, small manufacturers are not just adopting software; they are investing in a comprehensive strategy for efficiency, profitability, and an undeniable competitive edge. The time has come to stop managing raw materials inventory reactively and start controlling it seamlessly, paving the way for sustainable growth and a more resilient, agile manufacturing future.