Starting a new manufacturing venture is an exhilarating journey, filled with innovation, dedication, and a relentless pursuit of efficiency. But as any entrepreneur in this space will tell you, it’s also fraught with challenges, not least among them the need for robust operational infrastructure. You need to manage everything from raw materials and production schedules to sales, finances, and customer relationships. Traditionally, this is where an Enterprise Resource Planning (ERP) system steps in, a single software suite designed to integrate all these critical business functions. For a new manufacturing startup, however, the very mention of “ERP” can conjure images of astronomical costs and lengthy, complex implementations. This often leads to a crucial question: how do you get the power of ERP without breaking the bank? This comprehensive guide is dedicated to finding affordable Cloud ERP for new manufacturing startups, exploring how modern solutions offer the perfect blend of capability and cost-effectiveness, paving the way for sustainable growth.

Why Cloud ERP is a Game-Changer for Modern Manufacturing Startups

In the dynamic landscape of modern business, agility and cost-efficiency are paramount, especially for emerging manufacturing companies. Gone are the days when comprehensive business software was exclusively the domain of large enterprises with deep pockets. Cloud ERP, a revolutionary approach to business management, has leveled the playing field, making sophisticated tools accessible and affordable. For new manufacturing startups, the “cloud” aspect isn’t just a buzzword; it’s a strategic advantage that addresses many common pain points right out of the gate. It frees you from the burden of managing on-premise servers, costly IT infrastructure, and the constant need for software updates, allowing your lean team to focus on what they do best: innovating and producing.

Cloud ERP solutions significantly reduce upfront capital expenditure, moving from a large, one-time investment to more manageable, predictable monthly or annual subscription fees. This shift in financial model is often a lifeline for startups operating with tight budgets and needing to preserve capital for core manufacturing operations like equipment and raw materials. Furthermore, the inherent scalability of cloud platforms means your ERP system can grow seamlessly with your business. As you expand production, add new product lines, or enter new markets, your cloud ERP can adapt without requiring a complete overhaul or significant additional investment in hardware. This flexibility is crucial for a startup whose growth trajectory might be rapid and unpredictable. Beyond the cost savings and scalability, cloud ERP also offers unparalleled accessibility, enabling your team to access critical business data and tools from anywhere, at any time, on any device with an internet connection. This is particularly beneficial for manufacturing operations that might involve remote teams, off-site sales, or international supply chains, fostering a truly connected and collaborative work environment.

Understanding ERP: More Than Just Software for Your Factory Floor

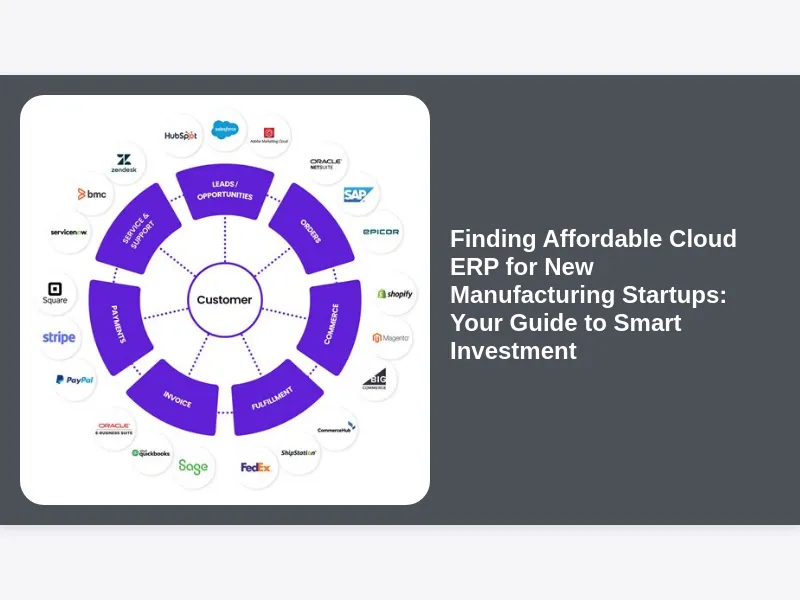

Before diving into the “affordable” aspect of finding affordable Cloud ERP for new manufacturing startups, it’s essential to truly grasp what an ERP system is and, more importantly, what it can do for your specific manufacturing operations. Many entrepreneurs hear “ERP” and envision a complex, monolithic system that’s too big and too much for their nascent business. In reality, ERP, or Enterprise Resource Planning, is a powerful suite of integrated applications that manages and streamlines core business processes. It’s designed to break down the traditional silos between different departments – from sales and accounting to production, inventory, and human resources – by providing a single, unified database and consistent user interface. This integration is what makes ERP so valuable.

For a manufacturing startup, an ERP system acts as the central nervous system of your entire operation. Imagine having real-time visibility into your inventory levels, knowing precisely when to order more raw materials to avoid production delays, or instantly tracking the status of every work order on your shop floor. An ERP enables this and much more. It handles your accounting and financial management, tracks customer orders, manages your supply chain, streamlines production planning and scheduling, and provides crucial insights through reporting and analytics. Without an ERP, these functions are often managed using disparate spreadsheets, manual processes, and disconnected software tools, leading to inefficiencies, errors, and a significant lack of critical data visibility. The true power of an ERP lies in its ability to provide a single source of truth for all your business data, allowing for better decision-making, improved efficiency, reduced waste, and ultimately, a more profitable and scalable manufacturing business.

The “Affordable” Conundrum for New Manufacturing Startups: Defining True Value

When it comes to finding affordable Cloud ERP for new manufacturing startups, the term “affordable” isn’t merely about the lowest sticker price. It’s a nuanced concept that encompasses much more than the initial subscription fee. For a startup, affordability must be viewed through the lens of total cost of ownership (TCO), return on investment (ROI), and the long-term strategic value the system provides. A seemingly cheap solution might come with hidden costs, lack critical features, or fail to scale with your growth, ultimately costing you more in missed opportunities, inefficiencies, and eventual replacement. Conversely, a slightly higher-priced solution that offers robust features, excellent support, and seamless scalability could prove to be the most affordable in the long run.

The challenge for new manufacturers is distinguishing between genuine cost-effectiveness and false economies. True affordability means getting the features you need, without paying for features you don’t, while also ensuring the system is reliable, easy to use, and supported by a reputable vendor. It also means considering the cost of implementation, potential training expenses, and the ongoing support fees. With cloud ERP, many of these “hidden” costs associated with on-premise systems (like hardware maintenance, software upgrades, and dedicated IT staff) are significantly reduced or eliminated, shifting the cost burden to the vendor. Therefore, when evaluating options, startups should scrutinize pricing models, understand what’s included in the subscription, inquire about implementation services, and consider the vendor’s reputation for customer support. By adopting a holistic view of affordability, new manufacturing startups can make a wise investment that supports their growth rather than hindering it.

Essential Features a New Manufacturing Startup Needs in Cloud ERP

For any new manufacturing startup, the effectiveness of a Cloud ERP solution hinges on its ability to deliver core functionalities that directly address the unique demands of production, inventory, and sales. When you’re finding affordable Cloud ERP for new manufacturing startups, it’s crucial to prioritize features that provide immediate value and lay a strong foundation for future expansion, without overcomplicating your initial setup or incurring unnecessary costs for bells and whistles you won’t use yet. The goal is to identify a system that supports your current operational needs while offering the flexibility to add more sophisticated modules as your business matures.

At a minimum, your chosen cloud ERP should offer robust inventory management, allowing you to track raw materials, work-in-progress, and finished goods with precision. This includes functionalities for cycle counting, lot tracking, and managing multiple warehouses, all critical for maintaining efficient production and avoiding stockouts or overstocking. Production planning and control are equally vital, encompassing features like Bill of Materials (BOM) management, work order generation, capacity planning, and shop floor scheduling. These tools ensure that your manufacturing processes are optimized, materials are available, and production deadlines are met. Beyond the factory floor, integrated financial management (general ledger, accounts payable, accounts receivable, and reporting) is non-negotiable for understanding your cash flow and profitability. Sales and customer relationship management (CRM) functionalities, even if basic, are important for managing orders, tracking customer interactions, and ensuring timely deliveries. Supply chain management features, such as vendor management and purchase order processing, are also critical for streamlining your procurement process. Focusing on these core areas ensures that your cloud ERP investment directly supports your most fundamental manufacturing and business operations, providing a solid platform for growth.

On-Premise vs. Cloud ERP: A Modern Manufacturing Startup’s Perspective

The debate between on-premise and cloud ERP has largely settled for many businesses, but for new manufacturing startups, understanding the distinct advantages of cloud-based solutions is paramount when finding affordable Cloud ERP for new manufacturing startups. Historically, ERP systems were almost exclusively deployed on-premise, requiring significant upfront capital for servers, software licenses, and dedicated IT staff for maintenance, security, and updates. While on-premise solutions offer a high degree of control over data and customization, these benefits come at a steep price, both financially and operationally, which is often prohibitive for a lean startup. The capital expenditure alone for hardware and initial software licenses can drain precious resources that are better invested in production equipment or marketing.

Cloud ERP, by contrast, operates on a Software-as-a-Service (SaaS) model, where the ERP software and its associated data are hosted on the vendor’s servers and accessed by users over the internet. This fundamental difference dramatically alters the cost structure and operational burden. Startups pay a subscription fee, which covers not only the software but also infrastructure, maintenance, security, and upgrades. This eliminates the need for expensive IT infrastructure and a large IT department, freeing up capital and human resources. Beyond cost, cloud ERP offers unparalleled scalability and flexibility. As your manufacturing business grows, you can easily add more users, modules, or storage capacity without investing in new hardware. Data accessibility from anywhere with an internet connection also fosters collaboration and agile decision-making, a crucial advantage in a fast-paced startup environment. While customization might be more restricted in some cloud solutions compared to on-premise, the benefits of lower TCO, faster implementation, and reduced IT overhead almost always outweigh this for new manufacturing startups focused on rapid growth and efficiency.

Evaluating Cloud ERP Vendors: Beyond the Price Tag for Your Manufacturing Operations

When you’re actively finding affordable Cloud ERP for new manufacturing startups, it’s tempting to let price be the sole determining factor. However, a shrewd entrepreneur understands that the long-term success of your ERP implementation hinges on much more than just the monthly subscription fee. A thorough evaluation of potential vendors is critical, looking beyond the initial cost to assess their reputation, industry expertise, support quality, and the overall fit with your manufacturing startup’s culture and future growth trajectory. A low-cost solution from an unreliable vendor could quickly turn into a costly nightmare of downtime, data errors, and poor support, ultimately eroding your operational efficiency and profitability.

Start by researching the vendor’s track record and reputation in the manufacturing sector. Do they have a proven history of serving businesses similar to yours in size and industry? Look for customer testimonials, case studies, and independent reviews. A vendor with deep expertise in manufacturing will understand your specific challenges, from inventory complexities and production scheduling to quality control and compliance, and their solution will likely be tailored to address these needs effectively. Equally important is the quality and availability of customer support. For a startup with limited IT resources, responsive and knowledgeable support is invaluable. Inquire about their support channels (phone, email, chat), response times, and the availability of training resources. Furthermore, consider the vendor’s commitment to ongoing development and innovation. A reputable vendor will regularly update their software with new features, security enhancements, and technological advancements, ensuring your ERP remains cutting-edge and future-proof. Finally, assess their integration capabilities; can their ERP seamlessly connect with your other essential tools like CAD software, e-commerce platforms, or shipping carriers? By taking a holistic approach to vendor evaluation, new manufacturing startups can make an informed decision that secures a reliable, scalable, and truly affordable cloud ERP partner.

Open-Source Cloud ERP Solutions: A Budget-Friendly Alternative for Lean Manufacturing?

For new manufacturing startups operating on extremely tight budgets, the appeal of open-source cloud ERP solutions can be significant. When finding affordable Cloud ERP for new manufacturing startups, open-source platforms often present themselves as a highly cost-effective alternative to proprietary software, primarily because they eliminate licensing fees. The core software is freely available, which can be a huge draw for businesses looking to minimize upfront expenditure. This model allows startups to download, modify, and distribute the software, offering a degree of flexibility and control that might not be available with closed-source systems. For a lean manufacturing operation, the ability to customize the code to precisely fit unique processes can be very appealing, assuming the internal expertise is available.

However, the “free” aspect of open-source ERP can be a bit misleading. While the software itself might not have a license cost, implementing and maintaining it often requires significant investment in other areas. Startups will need to factor in costs for hosting, professional implementation services (unless they have strong in-house IT and development skills), ongoing support, training, and potential customizations. Security patches and updates also fall to the user or a hired third party, which can be a continuous operational burden. The ecosystem around open-source ERP can be vibrant, with community forums and a network of developers, but the level of guaranteed support typically found with proprietary vendors is often absent. For some manufacturing startups, particularly those with a strong technical team willing to take on the management of the system, open-source can indeed be a viable and affordable path. For others, the hidden costs and the need for dedicated IT expertise might negate the initial savings, making a proprietary SaaS solution a more predictable and ultimately “affordable” choice. It’s a trade-off between control and convenience, and startups must carefully assess their internal capabilities and long-term needs before committing to an open-source model.

Industry-Specific Cloud ERP vs. Generic Solutions for Manufacturing Startups

The choice between a generic, broad-stroke cloud ERP and an industry-specific solution is a critical decision point when finding affordable Cloud ERP for new manufacturing startups. While generic ERP systems offer versatility and can be adapted to various industries, solutions tailored specifically for manufacturing often provide out-of-the-box functionalities that directly address the unique complexities of production environments. These can include advanced Bill of Materials (BOM) management, detailed production scheduling, quality control modules, material requirements planning (MRP), and compliance tracking, which are vital for efficient and compliant manufacturing operations.

Generic ERPs might require extensive customization to meet these specialized manufacturing needs, which can lead to increased implementation costs, longer deployment times, and potential complexities with future upgrades. Each customization represents a divergence from the standard software, potentially making the system harder to maintain and support. On the other hand, an industry-specific cloud ERP for manufacturing comes pre-configured with industry best practices embedded, minimizing the need for costly modifications. This often translates to a faster, smoother implementation and a quicker return on investment, as the system immediately aligns with your operational workflows. While industry-specific solutions might sometimes appear to have a higher initial price point, their deep relevance and reduced customization needs can make them significantly more affordable in terms of total cost of ownership and operational efficiency for a manufacturing startup. They allow you to hit the ground running with tools designed for your exact purpose, rather than trying to fit a square peg into a round hole. Therefore, evaluating solutions with a keen eye on their manufacturing-specific capabilities is paramount, even if a generic option initially seems cheaper.

Decoding Subscription Models and Pricing Structures for Cost-Effective ERP

Navigating the myriad subscription models and pricing structures is a crucial step when finding affordable Cloud ERP for new manufacturing startups. Unlike traditional on-premise software with large upfront license fees, cloud ERP operates primarily on a Software-as-a-Service (SaaS) model, which typically involves recurring payments. Understanding these models is key to budgeting effectively and avoiding unwelcome surprises down the line. Most cloud ERP vendors charge based on a combination of factors, including the number of users, the specific modules selected, and sometimes the volume of data or transactions processed.

The most common pricing model is user-based, where you pay a monthly or annual fee per user. It’s important to clarify whether “users” refer to concurrent users (those logged in at the same time) or named users (anyone with an account). For a small manufacturing startup, careful management of user licenses can significantly impact costs. Some vendors offer tiered pricing, with different levels of access or functionality at varying price points – for example, a “viewer” license might be cheaper than a “full access” license. Module-based pricing is also prevalent, where you pay for each specific functionality you need, such as inventory management, production planning, accounting, or CRM. This allows startups to start with essential modules and add more as they grow, effectively scaling their investment. Hidden costs can sometimes surface through data storage limits, API access fees, or premium support tiers, so always read the fine print. Ask vendors for a comprehensive breakdown of all potential costs, including implementation support, training, and any future upgrade fees. By thoroughly understanding these pricing structures, new manufacturing startups can select a cloud ERP that offers predictable costs and truly aligns with their budget and growth strategy.

Implementation Strategies for Startups: Keeping Costs Low and Efficiency High

Even the most affordable cloud ERP can become a financial burden if its implementation is poorly managed. For new manufacturing startups, a strategic, cost-conscious approach to implementation is vital when finding affordable Cloud ERP for new manufacturing startups. Unlike large corporations that might dedicate months or even years to complex, enterprise-wide deployments, startups need a lean, agile strategy that gets them up and running quickly, minimizes disruption, and delivers immediate value. The goal is to maximize efficiency from day one, ensuring your investment begins paying off without draining precious resources or halting production.

One highly effective strategy is a phased implementation. Instead of trying to roll out every single module simultaneously, begin with the most critical functionalities that address your immediate pain points – perhaps inventory management and core accounting. Once these are stable and your team is proficient, you can gradually introduce additional modules like production planning, CRM, or advanced reporting. This approach reduces the initial workload, lowers the risk of overwhelm, and allows your team to adapt incrementally. Leveraging the vendor’s standard configuration and best practices is also key; resist the temptation for extensive custom development in the early stages, as this significantly inflates costs and lengthens timelines. Cloud ERPs are often designed for quick deployment, and sticking to their out-of-the-box features where possible will keep your implementation lean. Furthermore, engaging a dedicated, internal project lead who understands both your business processes and the ERP system is crucial. This person can liaise effectively with the vendor, manage internal training, and ensure user adoption, which is paramount for a successful, cost-effective deployment. Finally, prioritize data migration carefully; focus on critical, clean data to avoid importing old errors or unnecessary historical information that complicates your new system.

Scalability: Future-Proofing Your Manufacturing Operations with Cloud ERP

For any new manufacturing startup, the ability to grow and adapt is not just desirable, it’s existential. This makes scalability a non-negotiable factor when finding affordable Cloud ERP for new manufacturing startups. Your initial ERP investment should not just solve today’s problems but also be capable of seamlessly accommodating tomorrow’s expansion, whether that involves increased production volume, new product lines, additional facilities, or a larger workforce. The inherent design of cloud ERP platforms makes them exceptionally well-suited to meet this demand, offering a significant advantage over rigid, on-premise systems.

The beauty of cloud ERP lies in its elastic nature. As your manufacturing operations expand, you can typically scale up your resources – adding more users, increasing storage capacity, or activating additional modules – with relative ease and often without significant downtime. This eliminates the need for costly hardware upgrades or a complete system overhaul as your business matures, a common pain point with traditional software. A cloud vendor manages the underlying infrastructure, ensuring that servers, databases, and network capacities can handle increased loads. This means your startup doesn’t have to predict its future IT infrastructure needs years in advance; instead, you can scale resources on demand, paying only for what you use. Furthermore, many cloud ERPs are built with multi-company and multi-currency capabilities, allowing for easy expansion into new business units or international markets without requiring separate software instances. When evaluating potential solutions, inquire about their performance under stress, their ability to add new users rapidly, and the ease with which new modules can be activated. Choosing a truly scalable cloud ERP ensures that your initial affordable investment continues to serve your manufacturing business effectively, supporting your growth rather than becoming a bottleneck.

Seamless Integration with Existing Systems: Building a Connected Manufacturing Workflow

In today’s interconnected business environment, no single software solution operates in isolation. For new manufacturing startups, ensuring that a chosen cloud ERP integrates smoothly with existing systems is a critical consideration when finding affordable Cloud ERP for new manufacturing startups. Your manufacturing operation likely relies on specialized software for various functions, such as CAD (Computer-Aided Design) for product design, PLM (Product Lifecycle Management) for managing product data, CRM for customer interactions, e-commerce platforms for online sales, or even specialized shop floor control systems. The power of an ERP is significantly amplified when it can communicate and share data seamlessly with these other vital tools, creating a truly unified and efficient digital workflow.

Without proper integration, data silos emerge, requiring manual data entry between systems, which leads to inefficiencies, errors, and outdated information. This not only wastes valuable time but also compromises the accuracy of your business intelligence, making it harder to make informed decisions. When evaluating cloud ERPs, inquire about their integration capabilities. Do they offer pre-built connectors for common manufacturing software and e-commerce platforms? Do they provide robust Application Programming Interfaces (APIs) that allow for custom integrations with niche or proprietary systems you might be using? A strong API framework is particularly valuable, offering flexibility for future integration needs as your technology stack evolves. A well-integrated cloud ERP system can automate data flow, reduce manual tasks, and provide a single, comprehensive view of your entire manufacturing operation, from design to delivery. This seamless exchange of information eliminates bottlenecks, improves data accuracy, and ultimately enhances overall operational efficiency, ensuring your affordable ERP investment delivers maximum value by connecting all aspects of your business.

Security and Data Compliance in Cloud ERP: Protecting Your Manufacturing Assets

For new manufacturing startups, entrusting sensitive business data to a cloud provider can initially raise concerns about security and compliance. However, when finding affordable Cloud ERP for new manufacturing startups, it’s crucial to understand that reputable cloud ERP vendors typically offer a level of security that often surpasses what a small startup could achieve on its own with on-premise systems. These vendors invest heavily in advanced security infrastructure, protocols, and expertise, making data protection a core part of their service offering. For a lean startup, this managed security becomes a critical component of affordability, as it mitigates the need for expensive in-house cybersecurity talent and infrastructure.

When evaluating cloud ERP solutions, startups should thoroughly investigate the vendor’s security measures. This includes asking about their data encryption practices (both in transit and at rest), physical security of their data centers, network security protocols (firewalls, intrusion detection), and their disaster recovery and business continuity plans. How often are backups performed, and where are they stored? What are their uptime guarantees? Furthermore, compliance with industry-specific regulations and data privacy laws (like GDPR, HIPAA if applicable, or local manufacturing standards) is paramount. Reputable cloud ERP providers often hold various certifications (e.g., ISO 27001, SOC 1/2) that demonstrate their adherence to strict security and operational standards. They should also be transparent about their data ownership policies, ensuring that your company retains full ownership and control over its data. By carefully scrutinizing these security and compliance aspects, new manufacturing startups can confidently leverage the benefits of cloud ERP, knowing their valuable intellectual property, customer data, and financial information are protected within a robust and professionally managed environment, transforming a potential concern into a significant advantage.

Training and User Adoption: Maximizing Your ERP Investment in Manufacturing

The most sophisticated and affordable cloud ERP system is only as good as the people who use it. For new manufacturing startups, focusing on training and fostering strong user adoption is paramount to realizing the full potential of their ERP investment. When finding affordable Cloud ERP for new manufacturing startups, it’s easy to overlook the human element, but poor user adoption can lead to inefficiencies, resistance, and ultimately, a system that underperforms, no matter how feature-rich or cost-effective it initially seemed. Effective training ensures that your team is proficient in using the new tools, understands their benefits, and can seamlessly integrate the ERP into their daily workflows, transforming potential friction into streamlined operations.

Startups should consider training as an integral part of the ERP implementation budget and timeline, not an afterthought. Reputable cloud ERP vendors often provide various training resources, including online tutorials, documentation, webinars, and sometimes even in-person workshops. Evaluate the quality and accessibility of these resources during your vendor selection process. Beyond formal training, fostering a culture of acceptance and enthusiasm for the new system is critical. Involve key users from various departments in the selection and implementation process early on. Their input can help shape the configuration and ensure the system meets their practical needs, making them advocates rather than resistors. Appoint internal “super-users” or champions who can become experts and provide ongoing peer support. Clear communication about the “why” – how the ERP will improve their jobs, reduce manual tasks, and ultimately benefit the company – can significantly boost morale and encourage adoption. Remember, a well-trained and engaged workforce will not only use the system effectively but also uncover new efficiencies and leverage features you might not have initially considered, ensuring your affordable cloud ERP delivers maximum ROI for your manufacturing startup.

Measuring ROI: Proving the Value of Your Cloud ERP for Manufacturing Growth

For new manufacturing startups, every investment, especially one as significant as an ERP system, needs to demonstrate a tangible return. When finding affordable Cloud ERP for new manufacturing startups, simply getting a low price isn’t enough; you need to prove that the system is contributing positively to your bottom line and overall operational health. Measuring the Return on Investment (ROI) of your cloud ERP goes beyond just cost savings; it encompasses improved efficiency, reduced errors, better decision-making, and enhanced customer satisfaction, all of which contribute to sustainable growth. Establishing key performance indicators (KPIs) before, during, and after implementation is crucial for accurately tracking these benefits.

Start by identifying your baseline metrics before the ERP is deployed. This could include inventory turnover rates, order fulfillment times, production cycle times, administrative hours spent on manual tasks, error rates in data entry, and even customer satisfaction scores. Once the cloud ERP is operational, continuously monitor these KPIs. For example, you might track a significant reduction in stockouts due to improved inventory management, leading to fewer production delays and happier customers. Real-time visibility into production schedules and capacity planning through the ERP can lead to optimized resource utilization and reduced overtime costs. Financial modules can provide quicker, more accurate reporting, enabling faster insights into profitability and cash flow, which in turn leads to better strategic decisions. Automation of routine tasks through the ERP frees up employee time, allowing your team to focus on higher-value activities like product innovation or process improvement. Don’t forget to account for the “soft” benefits as well, such as improved employee morale from less frustrating manual work, or the enhanced data security provided by the cloud vendor. By systematically tracking both direct cost savings and indirect efficiency gains, new manufacturing startups can clearly articulate and prove the immense value that their affordable cloud ERP investment brings to their evolving business.

Common Pitfalls to Avoid When Selecting Cloud ERP for Manufacturing Startups

The journey of finding affordable Cloud ERP for new manufacturing startups is filled with opportunities, but also potential pitfalls that can derail even the best-laid plans. Being aware of these common mistakes can save your startup significant time, money, and frustration. Avoiding these missteps is just as important as identifying the right features and vendor; it ensures your investment translates into genuine operational improvement rather than becoming a source of ongoing headaches.

One of the most frequent errors is under-scoping the project, where startups underestimate their actual needs or try to cut costs by selecting a solution that lacks essential functionalities. While it’s wise to start lean, choosing a system that cannot meet your core manufacturing requirements or scale with future growth will inevitably lead to frustration and potentially a costly re-implementation down the line. Conversely, over-scoping – trying to implement every possible feature and module from day one – can overwhelm a small team, inflate costs, and prolong implementation, delaying any tangible benefits. Another common pitfall is neglecting internal buy-in and training. A sophisticated ERP system is useless if your employees don’t understand how to use it or actively resist adopting it. Inadequate training and lack of communication about the system’s benefits can lead to low user adoption, data entry errors, and a general lack of enthusiasm. Furthermore, focusing solely on the lowest price without properly evaluating vendor support, scalability, and industry expertise is a dangerous trap. A cheap system with poor support or limited functionality can quickly become the most expensive option due to operational disruptions and missed opportunities. Finally, failing to clean and migrate data effectively can undermine the new system’s accuracy and integrity. Avoid these pitfalls by thoroughly planning, engaging your team, conducting due diligence on vendors, and understanding that “affordable” means long-term value, not just a low upfront cost.

Real-World Impact: How Cloud ERP Transforms Emerging Manufacturers (Hypothetical Case Study)

To truly appreciate the power of finding affordable Cloud ERP for new manufacturing startups, let’s consider a hypothetical scenario: “InnovateGear,” a startup specializing in custom-machined components for the robotics industry. InnovateGear began with spreadsheets for inventory, basic accounting software, and manual whiteboards for production scheduling. As orders grew, they faced escalating challenges: frequent stockouts of raw materials, difficulty tracking work-in-progress, delayed invoices, and inconsistent production schedules that led to missed delivery dates and frustrated customers. Their growth was stagnating due to operational inefficiencies.

Recognizing the urgent need for a more integrated solution, InnovateGear embarked on a search for an affordable cloud ERP. They evaluated several vendors, prioritizing manufacturing-specific modules, scalability, and predictable subscription costs. They ultimately chose a cloud ERP solution that offered robust inventory management, a simplified production planning module, and integrated accounting. Their implementation strategy was phased, starting with inventory and order-to-cash processes. Within three months, the transformation was remarkable. InnovateGear saw a 20% reduction in inventory carrying costs due to optimized stock levels and better forecasting. Production cycle times improved by 15% because of clearer scheduling and real-time visibility into the shop floor. Invoicing became instantaneous, improving cash flow significantly. The sales team, with access to real-time inventory and production data, could provide accurate delivery estimates, boosting customer satisfaction. Their accounting team, freed from manual data entry, could focus on strategic financial analysis. InnovateGear’s experience exemplifies how an affordable cloud ERP, carefully selected and strategically implemented, can not only resolve immediate operational headaches but also lay a strong foundation for rapid, sustainable growth, allowing a new manufacturing startup to compete effectively and thrive in a competitive market.

The Future Landscape: AI, IoT, and Automation in Cloud ERP for Manufacturing SMEs

As new manufacturing startups embark on finding affordable Cloud ERP for new manufacturing startups, it’s not just about addressing current needs, but also about positioning themselves for future technological advancements. The manufacturing industry is on the cusp of significant transformation driven by technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and advanced automation. Cloud ERP platforms, by their very nature of being constantly updated and accessible, are ideally situated to integrate these innovations, offering manufacturing SMEs capabilities previously reserved for large enterprises.

Imagine an ERP system that, through AI, can predict equipment maintenance needs before a breakdown occurs, optimizing your production schedule and minimizing downtime. Or an ERP that leverages IoT data from your shop floor sensors to provide real-time insights into machine performance, energy consumption, and product quality, automatically adjusting production parameters for maximum efficiency. Cloud ERPs are increasingly incorporating these capabilities, moving beyond traditional transaction processing to become intelligent operational hubs. They can automate complex decision-making, streamline supply chain logistics, and even personalize customer experiences. For a manufacturing startup, investing in a cloud ERP that has a clear roadmap for integrating these emerging technologies means future-proofing your business. It allows you to stay competitive, optimize resources, and innovate at a pace that was once unimaginable for a small enterprise. When evaluating solutions, inquire about the vendor’s vision for AI and IoT integration, as selecting a forward-thinking platform ensures your affordable ERP isn’t just a solution for today, but a springboard for tomorrow’s intelligent factory.

Your Strategic Partner in Growth: Navigating the Path to Affordable Cloud ERP

Embarking on the journey of finding affordable Cloud ERP for new manufacturing startups is more than just a software purchase; it’s a strategic decision that will profoundly impact your operational efficiency, profitability, and scalability. We’ve explored the myriad reasons why cloud ERP is a perfect fit for the modern manufacturing startup – from its inherent cost-effectiveness and scalability to its ability to integrate diverse business functions and offer robust security. We’ve delved into what constitutes true affordability, going beyond the sticker price to consider total cost of ownership, implementation strategies, and the critical importance of vendor support and user adoption. The key takeaway is that accessible, powerful ERP solutions are no longer out of reach for new, lean manufacturing ventures.

The path to success lies in careful consideration, thorough research, and a clear understanding of your specific needs and growth trajectory. Prioritize core manufacturing functionalities, scrutinize pricing models, and select a vendor that acts as a true partner, offering reliable support and a commitment to innovation. By avoiding common pitfalls and focusing on a phased, lean implementation, your manufacturing startup can leverage the transformative power of cloud ERP without breaking the bank. This investment isn’t just about managing your resources better; it’s about building a robust, agile foundation that empowers your team to innovate, produce efficiently, satisfy customers, and ultimately, scale your business into a thriving enterprise. The future of manufacturing is connected, efficient, and data-driven, and with the right affordable cloud ERP, your startup will be perfectly positioned to lead the way.