In the dynamic and often unpredictable world of retail, the ability to accurately foresee future demand is not just an advantage – it’s a necessity for survival and growth. From fashion cycles that shift with the seasons to sudden spikes in demand driven by social media trends or global events, retailers face a constant barrage of challenges that can disrupt even the most meticulously planned supply chains. Without robust forecasting, businesses risk everything from crippling overstock to frustrating stockouts, both of which erode profitability and customer loyalty. This is where Enterprise Resource Planning (ERP) systems step in, transforming the way retailers approach demand prediction.

This comprehensive guide will explore how ERP improves forecasting for retail supply chain planning, delving into the mechanisms, benefits, and strategic advantages these integrated systems offer. We’ll uncover how ERP centralizes critical data, leverages advanced analytics, and fosters cross-departmental collaboration, all contributing to a more precise and agile retail operation. Join us as we unravel the intricate ways ERP empowers retailers to navigate the complexities of their supply chains with greater confidence and strategic foresight.

The Volatile World of Retail Supply Chains: Why Precision Matters

The modern retail landscape is a whirlwind of evolving consumer expectations, rapid technological advancements, and increasing global interconnectedness. Shoppers today demand instant gratification, personalized experiences, and seamless omnichannel interactions. This pressure filters down through every layer of the supply chain, from raw material sourcing to last-mile delivery. Keeping shelves stocked with the right products, at the right time, and in the right quantities, is a monumental task when consumer preferences can pivot overnight.

Traditional forecasting methods, often reliant on historical averages and manual adjustments, simply can’t keep pace with this accelerating volatility. They struggle to account for the nuanced interplay of promotions, economic shifts, competitive actions, and unexpected external events. The result is often a reactive, rather than proactive, approach to inventory and logistics, leading to costly inefficiencies, missed sales opportunities, and ultimately, a diminished competitive edge. Understanding these inherent fragilities highlights the critical need for advanced tools that can cut through the noise and provide clearer insights into future demand.

What is ERP and Its Core Function in Retail Supply Chain Management?

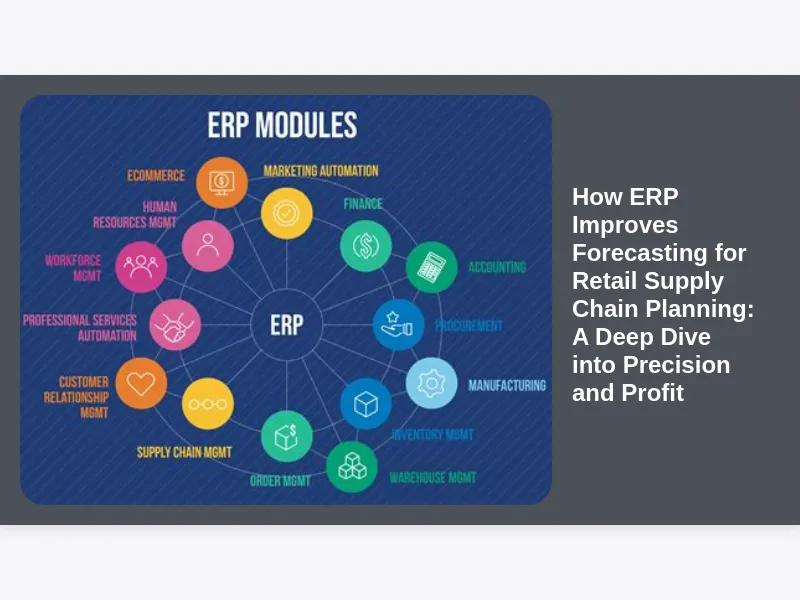

At its heart, an Enterprise Resource Planning (ERP) system is an integrated suite of software applications designed to manage and integrate all the core business processes of an organization. Think of it as the central nervous system of a retail enterprise, connecting disparate functions like finance, HR, inventory, sales, customer relationship management (CRM), and, crucially, supply chain management (SCM). Instead of siloed databases and fragmented processes, an ERP system offers a unified platform where data flows freely and consistently across departments.

For retail, this integration is particularly transformative. An ERP system gathers information from every touchpoint – point-of-sale (POS) systems, e-commerce platforms, warehouse management systems (WMS), supplier portals, and even external market data feeds. This comprehensive data capture forms the bedrock upon which more accurate and sophisticated forecasting models can be built. By providing a single source of truth, ERP eliminates discrepancies, reduces manual errors, and ensures that every department is working with the most current and consistent information, which is indispensable for effective retail supply chain planning.

Understanding the Pillars of Effective Retail Forecasting

Effective retail forecasting isn’t a shot in the dark; it’s a structured process built upon several foundational pillars. At its core, it involves analyzing historical data to identify patterns and trends, understanding the impact of planned events like promotions, accounting for predictable seasonal fluctuations, and staying aware of external factors that can influence consumer behavior. Each of these elements contributes vital pieces to the overall demand puzzle, and the more accurately they can be quantified and combined, the clearer the picture of future demand becomes.

However, the challenge often lies in gathering, cleansing, and integrating these diverse data points. Historical sales might reside in one system, promotional calendars in another, and market intelligence in yet a third. Without a unified approach, forecasters spend an inordinate amount of time on data reconciliation rather than analysis, leading to delays and potential inaccuracies. A robust system that can seamlessly bring these pillars together is essential for any retailer aiming to elevate their forecasting capabilities beyond mere guesswork.

Centralized Data Management: The Foundation for Better Forecasts

One of the most profound ways how ERP improves forecasting for retail supply chain planning is through its unparalleled ability to centralize data. In many traditional retail environments, information is scattered across a multitude of disconnected systems. Sales data might be in a POS system, inventory levels in a spreadsheet, customer preferences in a CRM, and supplier lead times in an entirely separate module. This fragmentation creates data silos, where critical insights remain trapped and inaccessible to the teams that need them most for accurate forecasting.

An ERP system shatters these silos, creating a single, integrated database where all operational data resides. This means that when a sale is made, inventory is updated instantly, customer profiles are enriched, and financial records are adjusted – all in real-time within the same system. This holistic view provides forecasters with an unprecedented level of data integrity and accessibility, ensuring that every prediction is based on the most current and complete information available, rather than fragmented snapshots or outdated reports. This foundational shift is what truly unlocks the potential for superior forecasting accuracy.

Harnessing Historical Sales Data for Predictive Accuracy

The past, in many ways, holds the key to the future, especially when it comes to retail demand. Historical sales data is an indispensable asset for forecasting, providing a rich tapestry of consumer behavior over time. However, merely looking at past sales figures isn’t enough; the data needs to be clean, granular, and easily digestible for analytical purposes. This is precisely how ERP improves forecasting for retail supply chain planning by transforming raw historical data into actionable insights.

An ERP system meticulously records every transaction, capturing details such as product IDs, quantities sold, prices, dates, locations, and even associated customer information. Over time, this builds an immense historical ledger that advanced analytics within the ERP can sift through. It allows retailers to identify long-term trends, pinpoint product lifecycles, and understand how demand fluctuates across different store formats or geographical regions. By having immediate access to years of consolidated, cleaned, and standardized historical data, forecasters can build more robust statistical models, spot recurring patterns that might otherwise go unnoticed, and make more informed predictions about future sales volumes.

Integrating Promotional Data and Marketing Insights

Promotions and marketing campaigns are powerful drivers of demand in retail, but their impact on forecasting is often difficult to quantify accurately. A major seasonal sale, a “buy one get one free” offer, or a targeted digital marketing push can dramatically alter sales patterns, creating temporary spikes or shifts that can skew traditional forecasting models if not properly accounted for. Understanding the direct correlation between promotional activities and sales uplift is crucial for precise retail supply chain planning.

An ERP system excels in this area by integrating marketing and promotional planning data directly with sales and inventory data. This capability shows how ERP improves forecasting for retail supply chain planning by allowing forecasters to model the expected impact of specific campaigns. They can analyze historical promotional effectiveness, understand which types of offers resonate with which customer segments, and factor these insights into future demand predictions. This integration ensures that forecasts aren’t just based on baseline demand, but also on the anticipated surge or dip that a carefully orchestrated marketing initiative is designed to create, leading to more accurate stock levels and preventing both overstocking and missed sales opportunities during peak promotional periods.

Accounting for Seasonality and Cyclical Trends

Seasonality is a fundamental characteristic of retail, influencing everything from fashion lines to grocery staples. Whether it’s the annual holiday rush, the summer spike in swimwear sales, or the back-to-school frenzy, these predictable cyclical patterns significantly impact demand. Failure to accurately account for seasonality can lead to shelves brimming with out-of-season merchandise or empty racks during peak periods, both detrimental to profitability and customer satisfaction.

ERP systems are designed with sophisticated algorithms that can detect and project these seasonal and cyclical trends with remarkable precision. By analyzing years of historical sales data, an ERP can identify recurring patterns, quantifying the average uplift or dip associated with specific weeks, months, or quarters. This allows forecasters to fine-tune their predictions, ensuring that inventory levels are appropriately adjusted for upcoming seasonal peaks and troughs. This capability is a prime example of how ERP improves forecasting for retail supply chain planning by embedding deep historical intelligence directly into the planning process, moving beyond simple month-over-month comparisons to capture the true rhythm of retail demand.

Incorporating External Factors and Market Intelligence

While internal data is invaluable, the retail supply chain operates within a broader ecosystem influenced by numerous external factors. Economic indicators like inflation or unemployment rates, weather patterns, competitor activities, social media sentiment, and even global geopolitical events can all significantly sway consumer behavior and demand. Integrating these external variables into forecasting models is a complex but crucial step toward achieving truly robust predictions.

Modern ERP systems offer increasing capabilities to connect with and analyze external data feeds. While not all ERPs come with direct integrations for every possible external data source, their open architecture often allows for APIs to pull in information from weather services, economic databases, news aggregators, or social listening tools. By correlating internal sales data with these external influences, ERP platforms illustrate how ERP improves forecasting for retail supply chain planning by offering a more holistic view of market dynamics. This integration empowers retailers to anticipate shifts driven by broader market forces, helping them prepare for potential disruptions or capitalize on emerging opportunities before they fully materialize.

Advanced Analytics and Machine Learning Capabilities within ERP

Moving beyond traditional statistical models, the cutting-edge of retail forecasting lies in the application of advanced analytics and machine learning (ML). ERP systems are increasingly incorporating these powerful tools, transforming raw data into highly accurate, predictive insights. Where older methods might rely on simple moving averages or exponential smoothing, ML algorithms can identify intricate, non-linear relationships and subtle patterns that are invisible to the human eye or simpler models.

These capabilities are central to how ERP improves forecasting for retail supply chain planning. Machine learning models can analyze vast datasets, learning from past performance to predict future outcomes with greater precision. They can factor in hundreds of variables simultaneously, including internal sales data, promotional history, external market indicators, and even unstructured data like customer reviews. This allows for dynamic demand sensing, where forecasts are continuously refined in real-time as new data becomes available, enabling retailers to react with unprecedented speed and agility to changing market conditions. The integration of AI and ML within ERP platforms is not just an enhancement; it’s a paradigm shift in forecasting accuracy.

Optimizing Inventory Management through Improved Forecasts

The direct consequence of improved forecasting is significantly optimized inventory management. In retail, inventory is a double-edged sword: too much ties up capital and incurs carrying costs, while too little leads to lost sales and disappointed customers. Accurate forecasts, powered by ERP, allow retailers to strike the perfect balance, ensuring that the right products are available at the right time without excessive overhead.

This optimization is a core reason how ERP improves forecasting for retail supply chain planning. By having a clearer picture of anticipated demand, businesses can reduce safety stock levels, minimize the risk of obsolescence for perishable or trend-driven items, and free up valuable warehouse space. Conversely, precise forecasts prevent stockouts during peak demand periods, ensuring customers can always find what they’re looking for. The financial benefits are substantial, including reduced inventory holding costs, fewer write-offs due to expired or unsold goods, and ultimately, a more efficient and profitable operation that consistently meets customer expectations.

Enhancing Supplier Collaboration and Supply Chain Visibility

A retail supply chain is a complex web of interconnected partners, from raw material suppliers to logistics providers. Effective collaboration and shared visibility are paramount for smooth operations and timely product delivery. However, in environments with poor forecasting, retailers often resort to last-minute, reactive orders, putting strain on suppliers and leading to longer lead times and higher costs.

This is another critical area how ERP improves forecasting for retail supply chain planning. By generating highly accurate demand forecasts, retailers can proactively share these predictions with their suppliers. This transparency allows suppliers to better plan their own production schedules, allocate resources more efficiently, and manage their raw material inventories, leading to more reliable delivery times and potentially lower procurement costs for the retailer. Furthermore, many ERP systems offer supplier portals, providing a shared platform for real-time order tracking, delivery status updates, and collaborative problem-solving, fostering stronger, more strategic partnerships across the entire supply chain ecosystem.

Streamlining Production and Distribution Planning

Beyond inventory management and supplier relations, improved forecasting has a profound impact on a retailer’s internal production and distribution strategies. For retailers that manufacture their own goods or have complex distribution networks, aligning production schedules and logistics plans with anticipated demand is crucial for operational efficiency and cost control. Mismatched plans can lead to costly overtime, underutilized machinery, or expensive rush shipping to compensate for shortfalls.

An ERP system, by providing precise demand forecasts, enables a synchronized approach to production and distribution. Manufacturers can schedule production runs more accurately, minimizing setup times and optimizing material flow. In distribution, warehouses can anticipate incoming stock, plan optimal picking routes, and arrange for appropriate transportation, leading to faster order fulfillment and reduced shipping costs. This holistic planning capability demonstrates how ERP improves forecasting for retail supply chain planning by ensuring every operational facet, from factory floor to store shelf, is working in harmony towards meeting customer demand efficiently and profitably.

Risk Mitigation and Agility in Retail Operations

The retail sector is inherently susceptible to various risks, from sudden shifts in consumer trends to global supply chain disruptions, economic downturns, or even natural disasters. Companies that lack accurate forecasting are often caught off guard, forced into reactive measures that are costly and inefficient. Building resilience and agility into operations is key to navigating these uncertainties.

This is where the predictive power of ERP becomes a vital asset. By providing more accurate and continuously updated forecasts, an ERP system acts as an early warning system. It highlights potential areas of concern, such as an anticipated dip in demand that could lead to excess inventory, or a projected surge that might strain existing supply lines. This foresight allows retailers to proactively implement mitigation strategies, such as adjusting order volumes, diversifying suppliers, or reallocating resources. This enhanced ability to anticipate and adapt illustrates how ERP improves forecasting for retail supply chain planning by building a more robust and responsive supply chain, significantly reducing vulnerability to unexpected events.

The Transformative Impact on Customer Experience

Ultimately, every improvement in retail operations, from inventory management to logistics, funnels back to enhancing the customer experience. In today’s competitive landscape, customers expect seamless availability, prompt delivery, and personalized interactions. Disappointed customers due to stockouts, delayed orders, or incorrect inventory information can quickly turn to competitors.

By elevating forecasting accuracy, ERP systems directly contribute to superior customer satisfaction. When demand is accurately predicted, retailers can consistently meet consumer expectations, ensuring that desired products are always in stock and available for purchase, whether online or in-store. This reliability builds trust and loyalty. Furthermore, the detailed sales data and customer insights within an ERP can inform personalized marketing campaigns and product recommendations, making the shopping experience feel tailored and intuitive. This direct link to customer happiness is perhaps the most significant, albeit indirect, benefit of how ERP improves forecasting for retail supply chain planning, solidifying a retailer’s market position.

Overcoming Challenges in ERP Implementation for Forecasting Success

While the benefits of ERP for forecasting are undeniable, a successful implementation is not without its challenges. Simply acquiring an ERP system isn’t a magic bullet; its effectiveness hinges on careful planning, robust data management, and enthusiastic user adoption. Common hurdles include the complexity of integrating diverse data sources, ensuring data quality, and managing organizational change.

Data migration and cleansing can be particularly daunting. Legacy systems often house inconsistent or incomplete data, which must be standardized before being fed into a new ERP to avoid the “garbage in, garbage out” syndrome. Furthermore, resistance to change from employees accustomed to older processes can hinder adoption and prevent the system from being fully leveraged. Addressing these challenges requires a strategic approach, including thorough data audits, comprehensive training programs, strong leadership buy-in, and a phased implementation strategy. Investing in these areas is crucial to unlock the full potential of how ERP improves forecasting for retail supply chain planning.

The Future of Retail Forecasting: ERP and Beyond

The journey of retail forecasting is far from over. As technology continues to evolve at a breathtaking pace, so too will the capabilities within and around ERP systems. The future promises even greater precision, agility, and automation in demand prediction, driven by advancements in artificial intelligence (AI), the Internet of Things (IoT), and blockchain technology.

ERP systems will continue to serve as the foundational hub, integrating data from an ever-expanding array of sources. Imagine IoT sensors providing real-time inventory updates from smart shelves, AI continually learning from customer interactions to predict individual preferences, or blockchain ensuring complete transparency and traceability across the entire supply chain. These innovations will further refine how ERP improves forecasting for retail supply chain planning, enabling predictions that are not just accurate, but also anticipatory and hyper-personalized. Retailers embracing these future-forward capabilities will be best positioned to thrive in an increasingly data-driven and connected world, ensuring their supply chains are not just resilient, but truly intelligent.

Conclusion: ERP – The Cornerstone of Predictive Retail Success

In the relentlessly competitive world of retail, accurate forecasting is the bedrock upon which efficient supply chains, satisfied customers, and sustainable profitability are built. The antiquated days of relying on intuition or fragmented spreadsheets are rapidly fading, replaced by the sophisticated, data-driven insights offered by modern Enterprise Resource Planning systems. We’ve explored in depth how ERP improves forecasting for retail supply chain planning, revealing its transformative power across every critical dimension.

From centralizing disparate data streams and harnessing vast historical sales information to integrating the nuances of promotions, seasonality, and external market intelligence, ERP provides a holistic and dynamic platform for demand prediction. Its advanced analytics and machine learning capabilities elevate forecasting from a retrospective exercise to a proactive, predictive science, leading to optimized inventory, enhanced supplier collaboration, streamlined operations, and ultimately, a superior customer experience. While implementation requires strategic effort, the long-term benefits of an ERP-driven forecasting strategy are profound, offering retailers not just a competitive edge, but a resilient and intelligent pathway to future success.