Are you a small manufacturer constantly grappling with the complexities of inventory? Do you find yourself asking where your raw materials are, how much finished product you really have, or why you’re always running out of essential components just when you need them most? If so, you’re not alone. Inventory management is one of the most critical, yet often most challenging, aspects of running a successful manufacturing operation, especially for smaller businesses. The good news? There’s a powerful solution that can transform your inventory chaos into streamlined efficiency: Enterprise Resource Planning (ERP).

This article will dive deep into how ERP optimizes inventory management in small manufacturing, exploring every facet of this transformative technology. We’ll uncover how an integrated ERP system can centralize your data, provide real-time visibility, enhance demand forecasting, streamline procurement, and ultimately save you time, money, and countless headaches. Get ready to discover how ERP can be the game-changer your small manufacturing business needs to thrive.

The Inventory Challenge for Small Manufacturing Businesses

Small manufacturing operations often face unique and amplified inventory challenges compared to their larger counterparts. Without dedicated departments or sophisticated systems, managing raw materials, work-in-progress (WIP), and finished goods can quickly become a monumental task. The consequences of poor inventory management – from production delays and dissatisfied customers to wasted capital and increased storage costs – are particularly detrimental to businesses operating on tighter margins and with fewer resources.

One common scenario involves relying on disparate spreadsheets, manual counts, and fragmented communication channels. This leads to inaccurate stock levels, frequent stockouts of crucial components, or conversely, excessive overstocking of slow-moving items. Each of these situations represents a direct hit to profitability and operational efficiency. Small manufacturers are often caught between the need to maintain sufficient stock to avoid production halts and the desire to minimize inventory holding costs. Finding that delicate balance without the right tools is akin to navigating a dense fog without a compass.

Understanding ERP Systems and Their Core Value

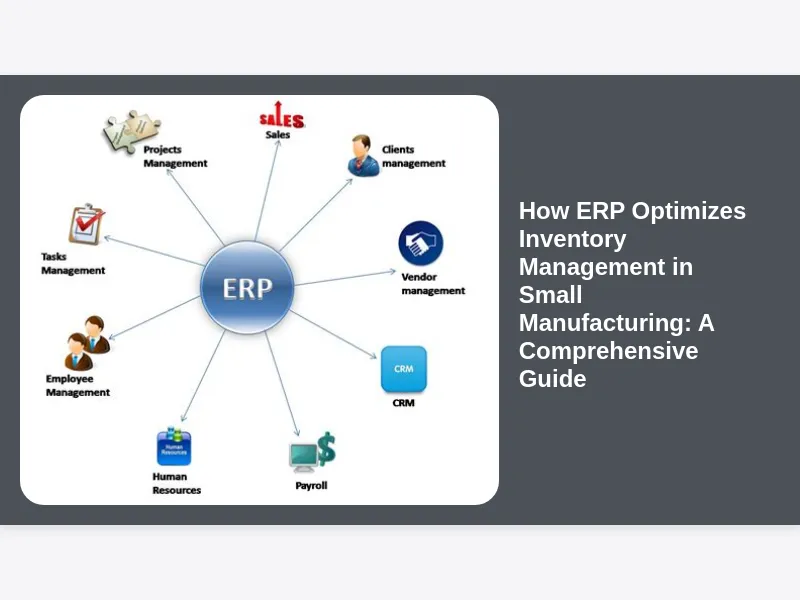

Before we delve into the specifics of inventory optimization, let’s establish a clear understanding of what an Enterprise Resource Planning (ERP) system truly is. At its heart, ERP is a suite of integrated software applications that an organization can use to manage daily business activities such as accounting, procurement, project management, risk management, compliance, and supply chain operations. For manufacturing, it’s about connecting every part of your business, from the sales order entering the system to the finished product leaving your dock.

The core value proposition of an ERP system lies in its ability to centralize data and processes. Instead of having separate, disconnected systems for sales, production, finance, and inventory, ERP brings them all under one roof. This integration means that information entered in one module, say a sales order, immediately updates relevant data in other modules, such as inventory levels and production schedules. This single source of truth eliminates data silos, reduces manual data entry errors, and provides a holistic view of your entire operation, laying the groundwork for significant improvements across the board.

Centralized Data: The Foundation of Optimized Inventory Management

Imagine a world where all your inventory information—what you have, where it is, when it’s due, and how much it costs—resides in one easily accessible location. This is precisely what an ERP system delivers through its centralized data management capabilities. For small manufacturers, moving away from fragmented data sources like individual spreadsheets, handwritten notes, and tribal knowledge is a monumental leap forward.

With ERP, every inventory transaction, from receiving raw materials to shipping finished goods, is recorded and updated in real-time within a single database. This means your sales team sees the same stock levels as your production team, and your purchasing department has an accurate picture of what needs to be reordered. This unified data approach eliminates discrepancies, prevents costly errors arising from outdated information, and ensures that everyone in your organization is working from the same, accurate set of facts. This foundation is absolutely crucial for making informed decisions about your inventory.

Real-time Visibility: Seeing Your Stock at a Glance

One of the most immediate and impactful benefits an ERP system brings to small manufacturing is real-time inventory visibility. Gone are the days of physically counting items or waiting for end-of-day reports to understand your stock levels. An ERP provides an always-on, dynamic view of your inventory at every stage of the manufacturing process. This means you can see current stock levels for raw materials, components in work-in-progress (WIP), and finished goods, all from a single dashboard.

This real-time insight extends beyond just knowing quantities. You can track the exact location of items within your warehouse, monitor their status (e.g., on hand, on order, reserved, in transit), and even view historical data on inventory movement. For a small manufacturer, this level of transparency is invaluable. It allows you to quickly identify potential bottlenecks, respond proactively to sudden changes in demand, and confidently commit to customer orders knowing you have the necessary stock available or can procure it in time. This immediate access to accurate information significantly reduces uncertainty and improves responsiveness.

Demand Forecasting Accuracy: Predicting What You’ll Need

Effective inventory management isn’t just about knowing what you have; it’s also about accurately predicting what you’ll need. For small manufacturers, poor demand forecasting often leads to either costly overstocking or crippling stockouts. ERP systems leverage historical sales data, seasonal trends, and even external market indicators to generate more precise demand forecasts, taking much of the guesswork out of the equation.

By integrating sales data, customer orders, and even marketing promotions, ERP can analyze patterns and identify trends that might be invisible to the human eye or through manual analysis. This intelligent forecasting helps you anticipate future demand for specific products or components, allowing you to optimize your purchasing and production schedules. The result is a significant reduction in the risk of carrying too much dead stock or, conversely, facing production delays because a critical part is unavailable. Better forecasting means your inventory levels are more closely aligned with actual customer demand, leading to higher efficiency and reduced costs.

Streamlining Procurement and Supplier Management

The process of acquiring raw materials and components can be a significant drain on resources for small manufacturers, especially if it’s handled manually or through disjointed systems. An ERP system dramatically streamlines procurement by automating many aspects of the purchasing cycle and integrating it directly with inventory levels and production needs. When stock levels dip below predefined reorder points, the ERP can automatically generate purchase requisitions or even purchase orders, sending them directly to approved suppliers.

Beyond automation, ERP also enhances supplier relationship management. It allows you to store and manage supplier information, including pricing agreements, lead times, and performance histories, all within one system. This visibility empowers you to make more informed decisions about who to buy from, negotiate better terms, and even identify opportunities for consolidating purchases to achieve economies of scale. By connecting procurement directly to inventory and production, ERP ensures that you get the right materials, at the right time, and at the right price, minimizing delays and improving cash flow.

Optimizing Order Management and Fulfillment Efficiency

From the moment a customer places an order until the product is delivered, efficient order management and fulfillment are crucial for customer satisfaction and operational profitability. An ERP system acts as the central hub for this entire process, integrating sales orders with inventory availability, production schedules, and shipping logistics. For small manufacturers, this means a significant reduction in errors and a dramatic increase in processing speed.

When a sales order is entered into the ERP, the system immediately checks inventory levels. If an item is in stock, it can be allocated, and the order can move directly to picking and packing. If an item needs to be manufactured, the ERP can initiate a production order, scheduling it based on material availability and current capacity. This seamless flow of information ensures that customers receive accurate delivery estimates, orders are fulfilled efficiently, and potential issues are identified and addressed proactively. By optimizing order management, ERP helps small manufacturers deliver on their promises, build customer loyalty, and enhance their reputation for reliability.

Minimizing Stockouts and Overstocking: The Goldilocks Zone

Perhaps one of the most compelling reasons for a small manufacturer to implement ERP for inventory management is its ability to help achieve the “Goldilocks Zone” – not too much inventory, not too little, but just right. Stockouts lead to missed sales, production delays, and unhappy customers, while overstocking ties up valuable capital, incurs storage costs, and increases the risk of obsolescence. ERP provides the tools to strike this delicate balance.

Through accurate demand forecasting, real-time inventory tracking, and automated reorder points, ERP systems significantly reduce the likelihood of both stockouts and overstocking. The system can alert you when an item is nearing its reorder level, prompting timely replenishment. Conversely, by providing insights into slow-moving or obsolete inventory, it helps you avoid unnecessary purchases and identify opportunities to clear out excess stock. This optimized inventory level frees up cash, reduces carrying costs, and ensures that you always have the right items on hand to meet production and customer needs without excessive waste.

Enhanced Warehouse Management and Location Tracking

For many small manufacturers, warehouse management often consists of a less-than-optimal system where items are stored wherever there’s space, leading to inefficient picking and frequent searches for misplaced goods. An ERP system, especially one with robust warehouse management capabilities, brings order and precision to your storage facilities. It allows for detailed tracking of every item, down to its specific bin or shelf location within the warehouse.

This enhanced location tracking drastically improves efficiency in several ways. Picking routes can be optimized, reducing the time and effort required to retrieve components for production or items for shipping. Cycle counting becomes more accurate and less disruptive, as you know exactly where to find specific items. Furthermore, ERP can help you optimize your warehouse layout by identifying frequently accessed items and suggesting more accessible storage locations. For small manufacturers, this means less time spent searching, faster order fulfillment, and a more organized and productive warehouse environment, turning a potential liability into a well-oiled asset.

Bill of Materials (BOM) Management and Production Planning

In manufacturing, the Bill of Materials (BOM) is the recipe for your product, listing all the raw materials, sub-assemblies, and components required to create a finished item. Managing complex BOMs and ensuring the availability of every single part is a critical task for small manufacturers. An ERP system centralizes and automates BOM management, linking it directly to inventory and production planning.

When a production order is initiated, the ERP automatically checks the inventory availability of all items listed in the BOM. If any components are missing or insufficient, the system can flag these shortages, trigger purchase orders, or adjust the production schedule accordingly. This integration prevents production from starting only to halt midway due to a missing screw or a critical component. Furthermore, ERP facilitates “what-if” scenarios, allowing you to easily adjust BOMs for product variations or new designs and immediately see the impact on material requirements and costs. This powerful connection between BOMs, inventory, and production planning is essential for smooth and efficient manufacturing operations.

Cost Reduction Through Efficient Inventory Practices

While the benefits of ERP for inventory management often focus on efficiency and accuracy, the underlying goal for any business is to reduce costs and improve profitability. An ERP system directly contributes to significant cost reductions for small manufacturers through its optimized inventory practices. By minimizing stockouts, it prevents costly production delays, expedites shipping fees, and lost sales opportunities. By reducing overstocking, it lowers carrying costs, insurance premiums, storage space requirements, and the risk of obsolescence.

Beyond these direct savings, ERP also reduces administrative costs associated with manual inventory management, such as time spent on physical counts, data entry, and reconciling discrepancies. It helps identify opportunities for bulk purchasing discounts by providing a consolidated view of material needs. Furthermore, by improving traceability and quality control (which we’ll discuss next), it reduces the costs associated with rework, scrap, and warranty claims. Essentially, an ERP system transforms inventory from a potential cost center into a lean, efficient component of your financial strategy, directly impacting your bottom line.

Quality Control Integration and Traceability

For many small manufacturers, especially those in regulated industries or those committed to high product standards, quality control and traceability are paramount. An ERP system can integrate quality management functionalities directly into its inventory and production modules, providing end-to-end visibility and control. This means you can track the journey of every component from the moment it enters your facility until it leaves as part of a finished product.

With ERP, you can record supplier certifications, track batch numbers for raw materials, link specific components to individual finished products, and manage quality inspection points throughout the production process. If a defect is discovered, the system allows for rapid identification of the affected batch or supplier, enabling quick containment and recall if necessary. This level of traceability not only enhances product quality and reduces the risk of costly recalls but also helps small manufacturers meet compliance requirements and build a stronger reputation for reliable, high-quality products. It transforms quality management from a reactive chore into a proactive, integrated part of your operation.

Scalability for Growth: ERP as a Future-Proof Solution

Small manufacturing businesses are often characterized by their ambition to grow. However, without scalable systems, growth can quickly lead to operational chaos, especially in inventory management. What works for 10 orders a day might completely break down at 100 orders a day. An ERP system is inherently designed to be scalable, making it an ideal future-proof solution for growing small manufacturers.

As your business expands, adding new product lines, increasing production volume, or entering new markets, your ERP system can seamlessly accommodate these changes. It can handle larger volumes of data, more complex production processes, and an increased number of users without significant overhauls. This means you won’t outgrow your inventory management solution just when your business hits its stride. Instead, your ERP system will evolve with you, continuing to provide the centralized data, real-time insights, and optimized processes you need to manage increasingly complex inventory challenges, ensuring your operational efficiency keeps pace with your business growth.

Choosing the Right ERP for Your Small Manufacturing Business

Implementing an ERP system is a significant investment, and choosing the right one is crucial for its success. For small manufacturers, the selection process should focus on several key factors. First, consider solutions specifically designed or highly adaptable to manufacturing, ensuring they have robust modules for production, BOM management, and shop floor control, not just generic business functions. The system should also be scalable, capable of growing with your business without requiring a complete re-implementation.

Ease of use and a friendly user interface are also paramount. Small businesses often have limited IT staff, so a system that is intuitive and easy to learn for your employees will accelerate adoption and maximize ROI. Cloud-based ERP solutions are often an excellent fit for small manufacturers, offering lower upfront costs, reduced IT infrastructure requirements, and greater flexibility for remote access. Finally, look for vendors with strong customer support and a proven track record of supporting businesses of your size and industry. Don’t be swayed by features you don’t need; focus on a solution that directly addresses your core challenges in inventory and production.

Implementation Considerations and Best Practices

Once you’ve chosen your ERP system, the implementation phase is critical. While it can seem daunting, a well-planned implementation can minimize disruption and ensure a smooth transition. For small manufacturers, it’s vital to approach this phase strategically. Start by clearly defining your objectives and identifying the specific inventory management challenges you want the ERP to solve. This clarity will guide the configuration and customization process.

Engage key stakeholders from all relevant departments – production, sales, finance, and warehouse – in the planning and testing phases. Their input is invaluable for configuring the system to match your actual workflows and ensuring user adoption. Data migration, moving your existing inventory data into the new system, requires careful planning and cleansing to ensure accuracy. Don’t underestimate the importance of thorough training for all users; proper training empowers your team to leverage the system’s full potential. Finally, consider a phased implementation, starting with a core module like inventory and gradually expanding to others, which can make the process more manageable and allow for iterative adjustments. A structured approach ensures that your ERP investment yields its promised benefits.

The Future of Inventory Management with ERP: AI and Beyond

The landscape of inventory management is continuously evolving, and ERP systems are at the forefront of incorporating cutting-edge technologies to deliver even greater optimization. For small manufacturers, understanding these emerging trends can help future-proof their operations. Artificial Intelligence (AI) and Machine Learning (ML) are increasingly being integrated into ERPs to enhance demand forecasting with unparalleled accuracy, moving beyond historical data to predict market shifts, customer behavior, and even geopolitical impacts.

Furthermore, the Internet of Things (IoT) is poised to revolutionize physical inventory tracking. Imagine smart shelves that automatically report stock levels, or sensors on raw materials that provide real-time location data and environmental conditions directly to your ERP. Predictive analytics, driven by AI, can anticipate equipment failures that might impact production and, consequently, inventory needs. As these technologies mature, ERP systems will offer small manufacturers even more sophisticated tools to manage inventory with unprecedented precision, agility, and foresight, making inventory management less about reaction and more about proactive, intelligent control.

Conclusion: Unlocking Manufacturing Potential with ERP

For small manufacturing businesses striving for efficiency, profitability, and sustainable growth, optimizing inventory management is not just an option—it’s a necessity. The manual, fragmented approaches of the past simply can’t keep pace with today’s dynamic market demands. This comprehensive exploration of how ERP optimizes inventory management in small manufacturing demonstrates that an integrated ERP system is far more than just software; it’s a strategic asset that transforms your operational capabilities.

By centralizing data, providing real-time visibility, enhancing demand forecasting, streamlining procurement, improving order fulfillment, and virtually eliminating stockouts and overstocking, ERP empowers small manufacturers to achieve unprecedented levels of control and efficiency. It reduces costs, improves quality, ensures scalability, and ultimately frees up valuable resources that can be reinvested into innovation and growth. Embracing an ERP system is not just about managing inventory better; it’s about unlocking your manufacturing business’s full potential, securing its future, and gaining a significant competitive edge in a challenging market. The time to optimize your inventory management with ERP is now.