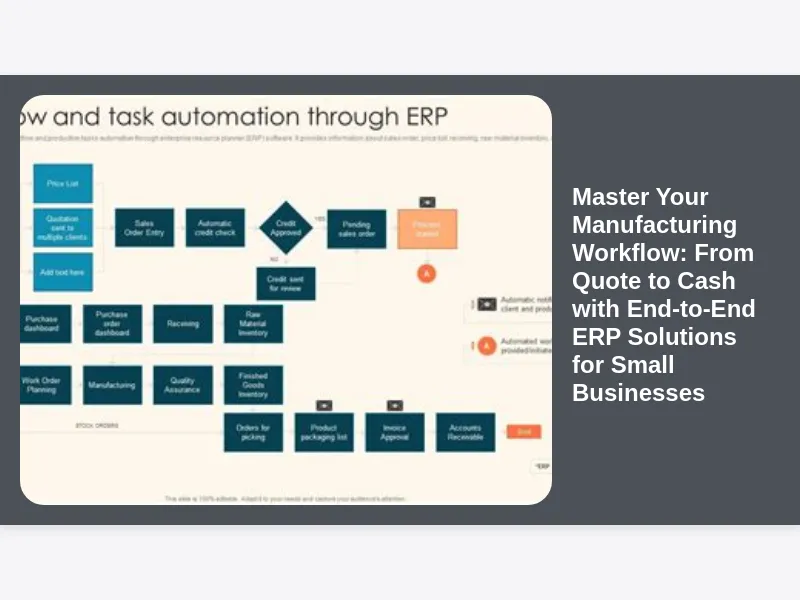

In the dynamic world of manufacturing, small businesses often find themselves juggling a complex array of tasks, from initial customer inquiries and accurate quoting to managing production, inventory, and ultimately, ensuring timely payment. The journey from quote to cash is the lifeblood of any manufacturing operation, but for small firms, it can often feel fragmented, inefficient, and riddled with manual processes that eat into profitability and growth potential. This is where the power of an End-to-End ERP Solution for Small Manufacturing truly shines, transforming chaotic workflows into a seamless, integrated, and highly efficient operation.

This comprehensive guide will delve deep into how an integrated Enterprise Resource Planning (ERP) system can revolutionize every stage of your manufacturing process. We’ll explore how these powerful tools connect disparate departments, provide real-time visibility, and empower small manufacturers to make smarter decisions, optimize resources, and ultimately, drive sustainable growth. Prepare to discover how moving from quote to cash can become a streamlined, predictable, and profitable journey for your small manufacturing enterprise.

The Fragmented Reality: Challenges Small Manufacturers Face Without Integrated Systems

Small manufacturing businesses often operate with a patchwork of disconnected software, spreadsheets, and manual processes. A sales team might use a basic CRM, production might rely on Excel for scheduling, inventory could be tracked in another standalone system, and accounting handles finances in yet another. This siloed approach creates significant hurdles, leading to miscommunication, data inaccuracies, and a constant struggle to gain a holistic view of the business. Orders get lost, production schedules are constantly adjusted, and material shortages disrupt timelines, all because information isn’t flowing freely and consistently across departments.

Imagine a customer requesting a custom order. The sales team drafts a quote, but they might not have real-time visibility into current raw material costs, production capacity, or lead times. This can lead to inaccurate pricing or unrealistic delivery dates. Once the order is placed, it has to be manually entered into a production schedule, which then needs to communicate with inventory to ensure materials are available. If an issue arises at any stage – a material delay, a machine breakdown, or a quality control problem – it often takes significant time and effort to identify, communicate, and resolve, impacting the entire from quote to cash cycle.

Understanding the “Quote to Cash” Cycle in Small Manufacturing: More Than Just Transactions

The “Quote to Cash” (Q2C) cycle is a critical business process that encompasses all the steps from generating an initial sales quote to receiving the final payment for goods delivered. For small manufacturers, it’s not just a sequence of transactions; it’s the core operational flow that defines customer satisfaction, operational efficiency, and financial health. This cycle begins long before production starts and extends well beyond the product leaving the factory floor, demanding intricate coordination and precise execution at every juncture.

Within a manufacturing context, the Q2C journey includes intricate steps like engineering specifications, bill of materials (BOM) creation, production routing, quality checks, and intricate logistics, all culminating in invoicing and payment collection. Without a unified system, each hand-off in this cycle becomes a potential point of failure, leading to delays, errors, and increased costs. A truly efficient from quote to cash process requires seamless data flow and a shared understanding across sales, engineering, production, procurement, and finance departments, a feat often elusive for small businesses relying on disparate tools.

The Power of End-to-End ERP: A Holistic Approach for Small Manufacturers

An End-to-End ERP system fundamentally changes how small manufacturers operate by integrating all core business functions into a single, unified platform. Instead of separate systems for sales, production, inventory, and accounting, ERP brings them all together, sharing a common database and processes. This holistic approach eliminates data silos, ensures information consistency, and provides a singular source of truth for all business operations. For a small manufacturing company, this means less time spent reconciling data and more time focusing on production and growth.

The “end-to-end” aspect is crucial because it means the system covers the entire journey from quote to cash. When a sales order is entered, it instantly updates production schedules, triggers material procurement, informs financial ledgers, and tracks inventory movements. This interconnectedness allows for unparalleled visibility into operations, enabling management to monitor key performance indicators (KPIs) in real-time and react swiftly to changing market conditions or internal challenges. It transforms a reactive business into a proactive one, laying a robust foundation for scalability and sustained success.

Streamlining the Quoting Process and Sales Order Management with ERP

The journey from quote to cash begins with an accurate and timely quote. For small manufacturers, generating quotes can be a tedious process, often involving manual calculations based on outdated cost data, leading to errors or uncompetitive pricing. An ERP system centralizes all relevant information, including raw material costs, labor rates, machine utilization, and overheads, allowing sales teams to generate precise quotes quickly. These quotes can factor in complex bills of materials (BOMs) and routing steps, ensuring that every component of the manufacturing process is accounted for in the final price.

Once a quote is accepted, the ERP seamlessly converts it into a sales order, eliminating redundant data entry. This sales order immediately flows through the system, initiating the subsequent steps in the manufacturing process. It can trigger material requirements planning (MRP), reserve inventory, or flag items for procurement. The integration with customer relationship management (CRM) functionalities within the ERP also ensures that all customer interactions, preferences, and order history are meticulously tracked, enhancing customer satisfaction and enabling personalized service throughout the entire from quote to cash cycle.

Robust Production Planning and Scheduling for Optimal Efficiency

Effective production planning and scheduling are the backbones of any successful manufacturing operation, especially for small businesses looking to optimize their resources. An integrated ERP solution provides sophisticated tools for material requirements planning (MRP) and capacity planning, crucial for ensuring that the right materials are available at the right time and that production capacity is utilized effectively. The system can automatically calculate material needs based on sales orders, existing inventory, and lead times, generating purchase requisitions or work orders as needed. This prevents costly delays due to material shortages and reduces unnecessary inventory holding costs.

Furthermore, ERP systems enable detailed scheduling of production activities, taking into account machine availability, labor resources, and specific process steps (routings). This allows small manufacturers to create realistic production schedules, identify potential bottlenecks before they occur, and proactively adjust plans to meet delivery deadlines. By optimizing the production flow, these solutions significantly contribute to reducing lead times, improving on-time delivery rates, and enhancing overall operational efficiency, directly impacting the speed and profitability of the journey from quote to cash.

Inventory Management: Balancing Stock and Demand with Precision

For small manufacturers, inefficient inventory management can be a significant drain on resources, tying up capital in excess stock or causing production delays due to shortages. An End-to-End ERP solution provides real-time, accurate visibility into inventory levels across all locations, from raw materials to work-in-progress and finished goods. This granular insight allows businesses to implement just-in-time (JIT) inventory strategies where appropriate, significantly reducing carrying costs and minimizing waste. The system tracks every movement, from goods receipt to issuance for production and final shipment, ensuring complete accountability.

Beyond tracking, ERP systems offer advanced features like demand forecasting and reorder point management. By analyzing historical sales data and current orders, the system can predict future demand patterns, helping small manufacturers optimize their purchasing decisions and maintain optimal stock levels. This proactive approach prevents costly stockouts that can halt production and delay deliveries, while also avoiding overstocking that ties up valuable cash flow. Efficient inventory management is a cornerstone of a smooth and profitable from quote to cash process, ensuring that products can be delivered as promised without unnecessary expenses.

Procurement and Supply Chain Management: Building Stronger Foundations

The efficiency of a small manufacturer’s supply chain directly impacts its ability to deliver products on time and within budget. An integrated ERP system transforms procurement from a reactive, manual process into a strategic function. It centralizes supplier information, tracks vendor performance, and automates the creation and approval of purchase orders based on material requirements generated by production planning. This streamlined process reduces administrative overhead, minimizes errors, and ensures that procurement activities are always aligned with production needs, accelerating the journey from quote to cash.

With an ERP, small manufacturers gain better control over their supply chain. They can monitor supplier lead times, track incoming shipments, and manage contracts and pricing agreements more effectively. This enhanced visibility and control allow businesses to identify and mitigate potential supply chain risks, negotiate better deals with vendors, and build stronger, more reliable relationships with key suppliers. By optimizing the flow of materials into the organization, an ERP system ensures that production is never stalled due to a lack of components, keeping the entire manufacturing operation running smoothly and efficiently.

Quality Control and Compliance: Ensuring Product Excellence

Maintaining high quality standards is paramount for small manufacturers to build a strong reputation and ensure customer satisfaction. An End-to-End ERP solution extends its reach into quality control by integrating quality management processes directly into the manufacturing workflow. From incoming material inspections to in-process quality checks and final product testing, the ERP can track and document every quality activity. This ensures that products meet specified standards and regulatory requirements, which is increasingly important in today’s global market.

The system can manage non-conformance reports, corrective and preventive actions (CAPA), and track product traceability, providing a complete audit trail from raw material to finished goods. This not only helps in identifying and resolving quality issues quickly but also provides valuable data for continuous improvement. For small manufacturing businesses, demonstrating a robust quality management system through ERP can be a significant competitive advantage, opening doors to new markets and customers who demand rigorous compliance. This assurance of quality is a vital component in successfully delivering on the promise made at the “quote” stage, cementing the success of the from quote to cash cycle.

Financial Management and Accounting Integration: Real-Time Fiscal Health

At the heart of every successful business, regardless of size, lies robust financial management. For small manufacturers, an End-to-End ERP system completely integrates all financial and accounting functions, providing real-time visibility into the company’s fiscal health. This integration means that every transaction – from a sales order and a purchase of raw materials to a production run and a customer payment – is automatically recorded and reflected in the general ledger, accounts receivable, and accounts payable modules. This eliminates manual data entry, reduces errors, and ensures that financial records are always up-to-date and accurate.

Beyond basic accounting, the ERP provides powerful tools for cost accounting, allowing small manufacturers to precisely track the true cost of production, including labor, materials, and overheads. This detailed cost analysis is crucial for accurate pricing, profitability analysis, and identifying areas for cost reduction. With integrated financial reporting, businesses can generate balance sheets, income statements, and cash flow reports instantly, empowering management with the insights needed to make informed financial decisions. This seamless financial integration ensures that the “cash” part of the from quote to cash cycle is efficiently managed and clearly understood.

Customer Relationship Management (CRM) for Lasting Connections

While often considered a separate discipline, effective Customer Relationship Management (CRM) is an integral part of the from quote to cash journey, especially for small manufacturers aiming for repeat business and sustained growth. Many modern ERP solutions for small manufacturing include robust CRM functionalities or integrate seamlessly with dedicated CRM modules. This allows businesses to centralize all customer-related data, from initial inquiries and quote history to past orders, service requests, and communication logs.

Having a 360-degree view of the customer empowers sales, service, and even production teams to provide a highly personalized and efficient experience. Sales teams can access order status in real-time, service teams can quickly address post-sales issues, and management can track customer satisfaction trends. By fostering stronger customer relationships and ensuring consistent, high-quality service throughout the entire lifecycle, ERP-integrated CRM not only helps secure initial orders but also builds loyalty, encourages repeat business, and strengthens the manufacturer’s market position, making the overall from quote to cash process more fruitful.

Benefits Beyond the Modules: The ROI of Integrated ERP for Small Manufacturing

The individual modules of an ERP system are powerful, but the true return on investment (ROI) for small manufacturers comes from their seamless integration. Beyond simply managing each function, an End-to-End ERP provides a synergistic effect that drives significant overall business improvements. One of the most immediate benefits is increased productivity. By automating repetitive tasks, eliminating manual data entry, and streamlining workflows, employees can focus on higher-value activities, leading to greater output with the same or even fewer resources.

Another critical benefit is reduced operational costs. ERP helps identify inefficiencies, minimize waste in materials and production time, optimize inventory levels, and reduce administrative overhead. This leads to a healthier bottom line. Furthermore, the real-time data and comprehensive reporting capabilities empower management with unprecedented insights, enabling better, faster, and more strategic decision-making. Small manufacturers can quickly identify trends, forecast challenges, and seize opportunities, ensuring agility and competitiveness in a rapidly changing market. Ultimately, the entire from quote to cash cycle becomes faster, more predictable, and more profitable.

Navigating ERP Implementation: A Roadmap for Small Manufacturers

Implementing an ERP system can seem daunting for a small manufacturing business, but with a well-planned roadmap, it can be a smooth and transformative process. The first crucial step is to define clear objectives: What specific problems are you trying to solve? What improvements do you expect to see in your from quote to cash cycle? This clarity will guide your selection process and ensure alignment with your business goals. Next, choosing the right ERP vendor and solution is paramount. Look for systems specifically designed for small manufacturers, offering industry-specific functionalities and a track record of successful implementations.

Once a system is selected, a phased implementation approach is often recommended, especially for smaller companies. This allows the business to gradually adopt the system, learn, and adapt without overwhelming operations. Data migration, moving your existing information into the new ERP, is a critical step that requires meticulous planning and execution to ensure accuracy and integrity. Finally, comprehensive training for all users is non-negotiable. User adoption is key to maximizing the ERP’s benefits, and adequate training ensures that employees are comfortable and proficient with the new system, minimizing disruption and accelerating the realization of your ERP investment.

Key Considerations When Choosing an ERP for Small Manufacturing

Selecting the right ERP solution is a pivotal decision that will impact your small manufacturing business for years to come. Beyond functionality, several key factors should guide your choice. Firstly, consider whether a cloud-based (SaaS) or on-premise deployment best suits your needs. Cloud ERP often offers lower upfront costs, easier maintenance, and greater accessibility, making it an attractive option for many small businesses. On the other hand, on-premise solutions provide more control over data and customization, though they require significant IT infrastructure investment and expertise.

Secondly, look for industry-specific features. A generic ERP might not cater to the unique complexities of manufacturing, such as complex BOMs, routings, or production scheduling needs. An ERP tailored for manufacturing will accelerate your from quote to cash process significantly. User-friendliness is also vital; a system that is intuitive and easy to navigate will drive better user adoption. Finally, consider scalability and vendor support. As your small manufacturing business grows, your ERP needs will evolve. Ensure the chosen system can scale with you and that the vendor provides reliable, responsive support to address any issues or questions that arise.

Overcoming Common Challenges in ERP Adoption for Small Manufacturers

While the benefits of an End-to-End ERP are undeniable, small manufacturers often face specific challenges during and after adoption. One of the most prevalent is resistance to change among employees. People are naturally accustomed to their existing workflows, even if they are inefficient, and introducing a new, complex system can be met with apprehension. To overcome this, strong leadership buy-in, clear communication about the benefits, and involving key users in the selection and implementation process can foster a sense of ownership and reduce anxiety.

Another common hurdle is data integrity. Migrating years of scattered data from spreadsheets and disparate systems into a new ERP can be prone to errors. Dedicate ample time and resources to data cleansing and validation before migration to ensure the accuracy of your new system. Scope creep, where new features or customizations are added throughout the implementation, can also derail projects. Stick to your initial objectives and prioritize essential functionalities first, then plan for future enhancements. Addressing these challenges proactively will ensure a smoother transition and a quicker realization of the ERP’s promise for your from quote to cash cycle.

The Future of Small Manufacturing with Advanced ERP Features

The landscape of manufacturing is continually evolving, driven by technological advancements. For small manufacturers, embracing an End-to-End ERP system today positions them perfectly to leverage the innovations of tomorrow. Advanced ERP solutions are increasingly integrating with emerging technologies like the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). IoT integration can connect machinery and sensors directly to the ERP, providing real-time data on machine performance, predictive maintenance needs, and production throughput. This allows for proactive interventions, minimizing downtime and optimizing efficiency throughout the from quote to cash process.

AI and ML capabilities within ERP can enhance demand forecasting, optimize production schedules with greater accuracy, and even identify patterns in quality control data to prevent defects before they occur. Furthermore, advanced analytics and business intelligence (BI) tools are becoming standard, providing deep insights into operational performance, profitability, and customer behavior. By investing in a modern, adaptable ERP, small manufacturers aren’t just solving today’s problems; they are building a future-proof foundation that can embrace these powerful technologies, staying competitive and agile in an increasingly complex global market.

Ensuring Data Security and Compliance with Modern ERP Systems

In an era of increasing cyber threats and stringent data privacy regulations, data security and compliance are paramount for small manufacturers. An End-to-End ERP solution, especially cloud-based ones, plays a critical role in safeguarding sensitive business information and ensuring adherence to industry standards and legal requirements. Reputable ERP vendors invest heavily in robust security infrastructure, including data encryption, regular backups, disaster recovery protocols, and stringent access controls to protect your intellectual property, financial data, and customer information.

For small manufacturers, outsourcing this complex security management to an ERP vendor often provides a higher level of protection than they could achieve independently. Furthermore, ERP systems can facilitate compliance with various regulations, such as industry-specific quality standards (e.g., ISO), environmental regulations, or financial reporting mandates. The system’s ability to maintain comprehensive audit trails, control access permissions, and generate compliance reports simplifies the burden of meeting these requirements. This peace of mind allows small manufacturers to focus on their core business, knowing their data and operations are secure and compliant throughout the entire from quote to cash journey.

Training and User Adoption: The Human Element in ERP Success

Even the most sophisticated End-to-End ERP solution will fail to deliver its full potential if its users aren’t adequately trained or don’t embrace the system. For small manufacturers, investing in comprehensive user training is not an option, but a necessity. Training should be tailored to different user roles, focusing on the specific modules and functionalities relevant to each department, from sales and production to procurement and finance. It’s important to move beyond generic software tutorials and provide practical, hands-on training that relates directly to the employees’ daily tasks and how the ERP will make their jobs easier and more efficient.

Beyond initial training, ongoing support and opportunities for continued learning are crucial for sustained user adoption. Creating internal champions who can assist colleagues, establishing clear support channels, and regularly soliciting feedback from users can help identify areas for improvement and ensure the system is being used to its fullest extent. When employees understand the “why” behind the ERP – how it streamlines the from quote to cash process, reduces errors, and contributes to the company’s success – they are far more likely to embrace it, transforming initial apprehension into proficient utilization and ultimately, driving the desired business outcomes.

Support and Maintenance: Post-Implementation Essentials for Small Manufacturers

Implementing an End-to-End ERP solution is not a one-time project; it’s the beginning of a long-term partnership with your system and its vendor. For small manufacturers, understanding the post-implementation support and maintenance landscape is crucial for the sustained success of their ERP. This includes regular software updates and patches, which ensure the system remains secure, performs optimally, and incorporates new features. Cloud-based ERPs often handle these updates automatically, simplifying the process for businesses with limited IT staff.

Furthermore, access to reliable technical support is indispensable. Whether it’s troubleshooting an issue, getting help with a specific function, or needing advice on system optimization, a responsive and knowledgeable support team from your ERP vendor can prevent minor problems from escalating into significant disruptions. Regular system health checks and performance monitoring can also help identify potential issues before they impact operations. By ensuring continuous support and maintenance, small manufacturers can maximize the lifespan and effectiveness of their ERP, ensuring that their investment continues to drive efficiency in every step from quote to cash.

Measuring Success: KPIs and Analytics from Your ERP System

One of the most powerful advantages of an End-to-End ERP solution for small manufacturing is its ability to provide actionable data and analytics to measure performance and drive continuous improvement. By integrating all business processes, the ERP becomes a central repository for key performance indicators (KPIs) across sales, production, inventory, and finance. For instance, you can track on-time delivery rates, production cycle times, inventory turnover, gross profit margins per product, customer acquisition costs, and many other metrics that directly reflect the efficiency of your from quote to cash cycle.

The ERP’s reporting and dashboard capabilities allow management to visualize these KPIs in real-time, providing immediate insights into operational health and areas needing attention. This data-driven approach empowers small manufacturers to make informed decisions, identify bottlenecks, and pinpoint opportunities for optimization. By regularly reviewing these metrics, businesses can not only assess the ROI of their ERP investment but also continuously refine their processes, setting new benchmarks for efficiency and profitability. This continuous feedback loop ensures that the journey from quote to cash is not just managed, but constantly improved.

Conclusion: Unleashing Growth and Efficiency from Quote to Cash

The journey from quote to cash is the defining pathway for profitability and growth in small manufacturing. Traditionally, this path has been fraught with disconnected systems, manual errors, and a lack of real-time visibility, holding back even the most ambitious small businesses. However, as we’ve explored, an End-to-End ERP Solution for Small Manufacturing offers a transformative solution, weaving together every thread of your operation into a cohesive and efficient whole.

By integrating sales, production, inventory, procurement, quality control, and financial management onto a single platform, ERP eliminates silos, streamlines workflows, and empowers small manufacturers with the insights needed to thrive. From generating accurate quotes and optimizing production schedules to managing inventory with precision and ensuring timely payments, an ERP system ensures that every step of the from quote to cash cycle is optimized for efficiency and profitability. It’s an investment not just in software, but in the future resilience, agility, and growth of your manufacturing enterprise, setting the stage for sustained success in a competitive market.