Embarking on an Enterprise Resource Planning (ERP) system implementation is a significant undertaking for any organization, but for small production plants, the stakes are arguably even higher. The very thought of operational disruption, let alone significant downtime, during a critical ERP go-live can send shivers down the spine of plant managers and owners. In a landscape where lean operations and tight margins are the norm, every minute of lost production directly impacts profitability and customer satisfaction. This comprehensive guide delves deep into the strategies and best practices specifically tailored for minimizing downtime during ERP go-live for small production plants, ensuring a smooth transition and rapid return on investment.

Understanding the Stakes: Why Downtime is Catastrophic for Small Production Plants

For larger enterprises, a few hours or even a day of reduced operations during an ERP go-live might be absorbed, albeit uncomfortably, within their vast resources and diversified operations. However, for a small production plant, such an event can be nothing short of catastrophic. These plants often operate with limited buffer inventory, a smaller workforce, and a more concentrated customer base. Any disruption can ripple through their entire value chain, leading to missed deadlines, penalties, damaged customer relationships, and significant financial losses that are difficult, if not impossible, to recover from. The continuous flow of production is their lifeblood, and any stoppage, no matter how brief, can have severe and lasting consequences.

The impact extends beyond immediate financial losses. Employee morale can plummet if they face prolonged periods of frustration with a new, non-functional system or are forced to return to inefficient manual processes. The reputation of the plant, built painstakingly over years, can be severely tarnished if product delivery commitments are not met. Therefore, the primary objective during an ERP go-live for these plants must unequivocally be minimizing downtime during ERP go-live for small production plants through meticulous planning and execution. It’s not just about getting the new system up and running; it’s about doing so without skipping a beat in production.

Strategic ERP Selection: Choosing the Right System for Your Production Needs

The journey toward a smooth ERP go-live begins long before any implementation work starts – it commences with the initial selection of the ERP system itself. For small production plants, this step is paramount. The temptation might be to opt for a large, enterprise-grade solution, but often, a more tailored, industry-specific, or modular ERP system designed with small and medium-sized businesses (SMBs) in mind will prove far more suitable. Such systems often come with pre-configured best practices for manufacturing, reducing the need for extensive customization which can be a major source of complexity and, subsequently, downtime during go-live.

A system that aligns closely with your existing business processes, or offers straightforward ways to adapt them, will inherently be easier to implement and less prone to disruption. Consider solutions known for their ease of use, intuitive interfaces, and robust, yet flexible, core manufacturing functionalities. Engage potential vendors in detailed discussions about their track record with small production plants, specifically inquiring about their strategies for minimizing downtime during ERP go-live for small production plants. Request references from similar-sized companies in your industry to gain insight into their real-world implementation experiences and the support they received.

Thorough Pre-Implementation Planning: Laying the Groundwork for Success

Once an ERP system is selected, the pre-implementation planning phase becomes the bedrock upon which the entire project’s success rests. This is where a detailed project plan is crafted, scope is defined, and resources are allocated. For small production plants, a common pitfall is underestimating the time and effort required for this phase, often due to limited internal resources. However, skimping here invariably leads to complications and increased risk of downtime later on. Designate a dedicated project manager, even if it’s a part-time role for an existing employee, to oversee all activities and act as the central point of contact.

The planning process must meticulously outline every step, from data cleansing to user training, with clear timelines, responsibilities, and success metrics. It’s crucial to involve key stakeholders from all relevant departments – production, inventory, sales, finance – right from the start. Their input will ensure that the system is configured to meet actual operational needs, thereby reducing the likelihood of last-minute changes or post-go-live issues that could disrupt production. A well-defined project scope, with clear boundaries on what the ERP will and will not do in the initial phase, is also vital for minimizing downtime during ERP go-live for small production plants. Avoid scope creep, as it invariably delays timelines and introduces new variables that can lead to unforeseen problems.

Comprehensive Business Process Mapping: Aligning ERP with Plant Operations

Before you can effectively implement an ERP system, you must first truly understand your current state of operations. This involves a comprehensive exercise in business process mapping. Documenting existing workflows, identifying bottlenecks, and understanding how data flows between different departments is crucial. For small production plants, these processes might be informally managed or reside only in the heads of long-term employees. The ERP implementation provides an invaluable opportunity to formalize, optimize, and standardize these processes.

This mapping exercise serves two critical purposes: first, it helps in configuring the ERP system to best support your optimized processes, rather than simply replicating old, inefficient ones. Second, it highlights where the biggest changes will occur for employees, allowing for targeted training and change management efforts. By aligning the ERP’s capabilities with refined business processes, you not only improve efficiency post-go-live but also significantly reduce the potential for disruption during the transition. A clear understanding of “how we do things now” versus “how we will do things with the new ERP” is fundamental for minimizing downtime during ERP go-live for small production plants and fostering user adoption.

Robust Data Migration Strategies: Ensuring Accuracy and Integrity

Data is the lifeblood of any ERP system, and the migration of existing data from legacy systems or spreadsheets into the new ERP is one of the most critical and often underestimated aspects of the entire project. Inaccurate, incomplete, or poorly formatted data can render a new ERP system useless, causing significant operational paralysis and leading directly to extended downtime. For small production plants, data quality issues can stem from years of ad-hoc data entry, inconsistent formats, and a lack of centralized data governance. Therefore, a robust and systematic approach to data migration is non-negotiable.

The process should begin with a thorough data audit and cleansing effort, identifying and rectifying errors, duplicates, and outdated information. Define clear data ownership and establish data validation rules that align with the new ERP’s requirements. Develop a detailed data migration plan, including mapping old fields to new, defining transformation rules, and establishing a clear cutover strategy for data. Conduct multiple dry runs of the data migration process in a test environment, comparing the migrated data against source data to ensure accuracy and completeness. This iterative testing is crucial for minimizing downtime during ERP go-live for small production plants by catching data issues long before they impact live operations.

System Integration and Interface Development: Connecting Disparate Systems

In many small production plants, the new ERP system will not operate in isolation. It will likely need to integrate with other specialized systems, such as CAD software, shop floor control systems (SCADA/MES), quality management tools, or even e-commerce platforms. The development and testing of these integrations and interfaces are complex tasks that, if not managed carefully, can introduce significant vulnerabilities and become major sources of downtime during go-live. Each integration point represents a potential failure point, and their robustness directly impacts the overall stability of the new environment.

It is essential to identify all necessary integrations early in the planning phase. Prioritize critical interfaces that directly impact production and ensure they are developed and rigorously tested first. Avoid the temptation to build overly complex or custom integrations if simpler, off-the-shelf connectors or standard API integrations are available. Partner closely with your ERP vendor and any third-party system providers to ensure compatibility and proper data flow. Thoroughly document all integration points, including data fields, transfer frequencies, and error handling mechanisms. This meticulous attention to detail during integration development is key to minimizng downtime during ERP go-live for small production plants by ensuring all interconnected systems communicate seamlessly from day one.

Rigorous Testing and Validation: From Unit to User Acceptance Testing (UAT)

Testing is not an optional extra; it is the cornerstone of a successful and low-downtime ERP go-live. For small production plants, the testing phase must be comprehensive and multi-layered, evolving from individual component tests to full end-to-end process validations. Start with unit testing, where individual configurations, customizations, and integrations are verified in isolation. This ensures that each piece of the puzzle functions as intended. Move on to integration testing, where connected modules and external systems are tested together to confirm seamless data flow and process execution across the entire system landscape.

Crucially, the testing phase must culminate in User Acceptance Testing (UAT). This is where actual end-users, representatives from all departments that will interact with the ERP, engage with the system in a simulated production environment using realistic data and scenarios. UAT is invaluable for identifying issues that might have been missed by technical teams, such as usability challenges, workflow inefficiencies, or discrepancies with real-world operational requirements. Conduct multiple UAT cycles, addressing feedback and re-testing until users are confident in the system’s ability to support their daily tasks. This rigorous validation significantly contributes to minimizing downtime during ERP go-live for small production plants by catching problems when they are much easier and less costly to fix.

Empowering Your Team: Effective User Training and Change Management

A technically perfect ERP implementation can still fail if users are not adequately prepared or are resistant to change. For small production plants, where a close-knit team often means shared responsibilities, the impact of disgruntled or untrained users can be particularly acute, leading to operational bottlenecks and reduced productivity, which directly translates to downtime. Effective user training and a proactive change management strategy are therefore critical components of a successful go-live strategy. Training should go beyond simply showing users how to click buttons; it should explain the “why” behind the changes and how the new system will benefit their daily work.

Develop a multi-faceted training program that caters to different learning styles and roles. This might include classroom sessions, online modules, hands-on workshops, and easily accessible reference materials. Identify super-users or champions within each department who can provide peer support and act as initial points of contact for questions. Furthermore, actively manage the change process by communicating regularly and transparently about the project’s progress, its benefits, and what users can expect. Address concerns openly and foster a culture of excitement rather than fear. Empowered and well-trained users are less likely to make errors or struggle with the new system, thereby minimizing downtime during ERP go-live for small production plants by ensuring a smooth adoption curve.

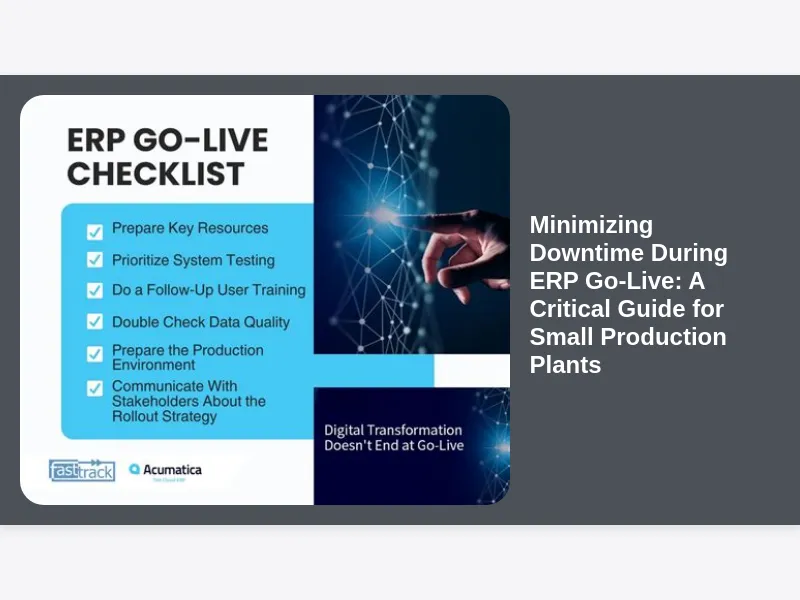

Crafting the Cutover Plan: A Detailed Roadmap for Go-Live Day

The cutover plan is the definitive playbook for the actual go-live event. It’s a highly detailed, step-by-step sequence of tasks that must be executed in a specific order to transition from the old system to the new ERP. For small production plants, this plan must be meticulously crafted, taking into account every minute of potential disruption to production. It should outline responsibilities, timings, dependencies, and communication protocols for every single activity, from the final data migration to the switching off of legacy systems and the initial startup of the new ERP modules.

This plan needs to specify precise timings, even down to 15-minute intervals for critical tasks, especially those that directly impact production equipment or scheduling. Identify key decision points where progress is reviewed, and a “go/no-go” decision is made. Include contingency steps for every major task, outlining what to do if an issue arises. The cutover plan should be extensively reviewed by all stakeholders, including the ERP vendor and any third-party integrators, to ensure alignment and identify any potential gaps. A well-executed cutover plan is the ultimate tool for minimizing downtime during ERP go-live for small production plants by orchestrating a highly controlled and efficient transition.

The Phased Approach vs. Big-Bang: Weighing Go-Live Methodologies

When it comes to the actual moment of truth, small production plants face a critical decision: should they opt for a “big-bang” go-live, switching all modules over at once, or a “phased” approach, implementing modules incrementally? Each method has its pros and cons, and the optimal choice often depends on the plant’s specific risk tolerance, complexity, and resource availability. A big-bang approach, while potentially offering a faster overall transition and avoiding the complexity of running parallel systems, carries a higher inherent risk of massive disruption if something goes wrong. For small plants with limited resilience, this can be extremely daunting.

A phased approach, where critical modules are rolled out first (e.g., inventory and production, followed by finance and HR), generally carries less risk of major downtime. It allows the plant to adapt gradually, learn from initial rollouts, and address issues in smaller, more manageable chunks. While it might extend the overall implementation timeline and require temporary interfaces between old and new systems, it significantly reduces the pressure on go-live day. For minimizing downtime during ERP go-live for small production plants, the phased approach often presents a more palatable and safer option, allowing for continuous operation while adjustments are made and users gain confidence.

Building a Contingency Plan: Preparing for the Unexpected

No matter how meticulous your planning, unforeseen issues can and often do arise during an ERP go-live. For small production plants, the ability to react quickly and effectively to these challenges is paramount to minimizing downtime during ERP go-live for small production plants. Therefore, developing a robust contingency plan is not a sign of pessimism but rather a demonstration of thorough preparation. This plan should detail specific actions to be taken for various potential failure scenarios, from critical system failures to data migration errors or unexpected user issues.

The contingency plan should identify key decision-makers and their roles in crisis situations. It should outline communication protocols, both internally and externally (e.g., informing critical customers if production is truly impacted). Crucially, it must include a clear rollback strategy: what steps would be taken to revert to the old system if the new ERP deployment encounters a catastrophic failure that cannot be immediately resolved. This “exit strategy” provides a crucial safety net, giving the plant confidence that they can recover without permanent damage, even in the worst-case scenario. Regularly review and update this plan throughout the project lifecycle.

Pre-Go-Live Dry Runs and Simulations: Rehearsing for Reality

Just as a theatrical production has dress rehearsals, an ERP go-live for a small production plant needs rigorous dry runs and simulations. These are not just additional rounds of testing; they are full-scale, end-to-end rehearsals of the entire cutover process, conducted in a non-production environment. The goal is to simulate the go-live event as closely as possible, including data migration, system switch-over, and initial transactions, all within the defined cutover window. This allows the team to practice the sequence of events, identify bottlenecks, refine timings, and test communication channels without the pressure of live operations.

Conduct at least one, and ideally several, comprehensive dry runs. Involve all key personnel who will be part of the actual go-live team, from IT staff to production supervisors and finance personnel. Pay close attention to the timing of each step and identify any tasks that take longer than anticipated. Use the dry runs to validate the contingency plan and practice rollback procedures. Each simulation provides invaluable feedback, helping to iron out wrinkles and build confidence within the team, which is essential for minimizing downtime during ERP go-live for small production plants by transforming the unknown into a practiced routine.

Dedicated Go-Live Support Team: On-Site Expertise for Smooth Transition

The days immediately following an ERP go-live are often referred to as the “hypercare” period. For small production plants, having a dedicated and readily available support team during this critical phase is absolutely non-negotiable for minimizing downtime during ERP go-live for small production plants. This team should comprise key internal project members, super-users, and crucially, representatives from the ERP vendor and any third-party integrators. Their presence, ideally on-site for at least the first few days, provides immediate assistance for any issues that arise, preventing minor glitches from escalating into major operational stoppages.

Establish clear channels for users to report issues and for the support team to track and resolve them. Implement a tiered support structure, with initial questions handled by super-users, escalating to internal IT, and then to the vendor as needed. Regular communication meetings within the support team and with plant leadership are vital to discuss critical issues, track resolution progress, and provide status updates. The goal is to rapidly address user queries, troubleshoot technical problems, and ensure that the plant’s operations continue as smoothly as possible, minimizing any friction points that could lead to production halts.

Post-Go-Live Monitoring and Optimization: Sustaining Performance

The successful go-live is not the end of the journey; it marks the beginning of continuous monitoring and optimization. For small production plants, establishing robust post-go-live monitoring mechanisms is crucial to ensure the new ERP system performs as expected and continues to support efficient operations, thereby sustaining the effort in minimizing downtime during ERP go-live for small production plants. This involves tracking key performance indicators (KPIs) related to production output, inventory accuracy, order fulfillment times, and financial reporting. Compare these metrics against pre-ERP benchmarks to measure the real impact of the new system.

Implement system performance monitoring tools to track response times, data processing speeds, and resource utilization. Proactively identify and address any performance bottlenecks or recurring issues. The first few weeks and months post-go-live are an ideal time to gather feedback from users on their experiences with the new system. This feedback can highlight areas for further training, configuration adjustments, or process refinements that can unlock even greater efficiencies. Continuous optimization ensures that the ERP system remains a valuable asset, constantly evolving to meet the plant’s changing needs and preventing future disruptions.

Establishing a Feedback Loop: Continuous Improvement Post-Launch

A critical element often overlooked after the initial go-live surge is the establishment of a formal feedback loop. For small production plants, this means creating an accessible and effective mechanism for users to submit suggestions, report non-critical issues, and ask questions that arise as they become more proficient with the ERP system. This continuous dialogue is invaluable for fine-tuning the system and processes, ultimately contributing to long-term operational stability and further minimizing downtime during ERP go-live for small production plants by addressing minor frustrations before they become major problems.

Regular “lessons learned” sessions should be scheduled, not just immediately after go-live, but also at three-month and six-month intervals. These sessions allow the project team and key users to reflect on what went well, what could be improved, and how the system’s utilization can be further optimized. Document all feedback, prioritize enhancements or fixes, and communicate resolutions back to the users. This not only improves the system but also fosters a sense of ownership and engagement among employees, ensuring the ERP remains a collaborative tool for enhancing overall plant efficiency.

Vendor Partnership and Communication: A Collaborative Effort

The relationship with your ERP vendor extends far beyond the software sale; it’s a critical partnership, especially during the go-live phase for small production plants. Open, honest, and frequent communication with your vendor is paramount for minimizing downtime during ERP go-live for small production plants. The vendor possesses deep knowledge of their system and best practices for implementation, and their expertise is an invaluable resource that should be fully leveraged. Establish clear communication channels and protocols from the outset, including designated points of contact on both sides.

Hold regular project meetings with the vendor to review progress, discuss challenges, and ensure alignment on timelines and deliverables. Be transparent about your plant’s operational constraints and risk tolerance. If issues arise, communicate them promptly and clearly, providing all necessary details. A strong vendor relationship, built on mutual trust and collaboration, means that when critical issues emerge during go-live, the vendor will be a proactive partner in finding rapid solutions, rather than just a distant support line. Their commitment to your success is a key determinant of a smooth transition.

Leveraging Cloud ERP for Small Plants: Benefits for Uptime

In the discussion of minimizing downtime during ERP go-live for small production plants, it’s worth highlighting the increasing relevance and benefits of cloud-based ERP solutions. Unlike traditional on-premise systems that require significant internal IT infrastructure, resources, and expertise to install, maintain, and upgrade, cloud ERP shifts much of this burden to the vendor. For small plants with limited IT staff, this can translate into substantial advantages for both implementation and ongoing uptime.

Cloud ERP implementations often involve less upfront hardware setup, potentially simplifying the go-live cutover process. More importantly, post-go-live, the vendor handles system maintenance, security updates, and performance optimizations, dramatically reducing the risk of internal infrastructure failures leading to downtime. Disaster recovery and data backup are typically built-in services, offering robust protection against data loss and operational interruptions. While still requiring thorough planning and data migration, the underlying infrastructure reliability provided by reputable cloud ERP vendors can be a significant factor in minimizing downtime during ERP go-live for small production plants and ensuring continuous operations.

Minimizing Downtime During ERP Go-Live: A Holistic View

Ultimately, achieving a smooth ERP go-live with minimal disruption for a small production plant is not about any single silver bullet; it’s the cumulative result of a holistic and integrated strategy encompassing every stage of the project. It’s about recognizing that every decision, from initial software selection to post-go-live support, impacts the potential for operational continuity. The goal of minimizing downtime during ERP go-live for small production plants demands a proactive, risk-aware, and thoroughly planned approach that places operational stability at its core.

This requires leadership commitment, cross-functional team collaboration, and a willingness to invest time and resources upfront in meticulous planning, robust testing, and comprehensive user preparation. It’s an investment that pays dividends by safeguarding production, maintaining customer trust, and ensuring that the new ERP system truly empowers the plant’s growth, rather than hindering it with unnecessary interruptions. Embrace each phase of the project as an opportunity to reinforce your commitment to a seamless transition.

Conclusion: Achieving a Smooth ERP Transition for Sustainable Growth

The prospect of an ERP go-live can be daunting for small production plants, but with the right strategies and a diligent approach, it doesn’t have to be a period of paralyzing downtime. By meticulously planning, rigorously testing, empowering your team, and maintaining a strong partnership with your vendor, you can navigate this critical transition with confidence. The focus must remain unwavering on minimizing downtime during ERP go-live for small production plants, transforming a potential threat into an opportunity for significant operational enhancement.

A well-executed ERP implementation lays the foundation for improved efficiency, better decision-making, and sustainable growth. It’s an investment in your plant’s future, enabling it to better compete in a dynamic market. By following the comprehensive guidelines outlined in this article, small production plants can not only survive their ERP go-live but thrive through it, emerging with a powerful new system that drives their success for years to come. The journey is challenging, but the rewards of a seamless transition are well worth the effort.