Hello there, fellow manufacturing innovator! If you’re running a small manufacturing plant today, you know the landscape is changing faster than ever. What worked yesterday might not cut it tomorrow. The good news? Technology is also evolving at lightning speed, offering powerful tools that were once exclusive to massive corporations. One such game-changer is the Cloud Enterprise Resource Planning (ERP) platform. This article is your comprehensive guide to selecting a Cloud ERP platform for your small manufacturing plant, helping you make an informed decision that will propel your business forward.

The Modern Manufacturing Dilemma: Why Cloud ERP is No Longer Optional

For years, small manufacturing plants relied on a patchwork of spreadsheets, basic accounting software, and perhaps some specialized, often siloed, production tools. This approach might have served its purpose when operations were simpler and competition less fierce. However, in today’s interconnected global economy, with demands for faster production, tighter inventory control, impeccable quality, and real-time data, this fragmented approach is simply unsustainable. You’re likely battling inefficiencies, delayed decisions, and a constant struggle to get a clear, unified view of your entire operation.

This is precisely where a robust ERP system steps in, and specifically, a Cloud ERP offers unique advantages for small to medium-sized businesses. Imagine having all your critical business processes – from order entry and procurement to production scheduling, inventory management, financial accounting, and even customer relations – integrated into one seamless system. That’s the power of ERP. And by moving it to the cloud, you unlock flexibility, scalability, and cost-effectiveness that traditional on-premise systems simply can’t match. We’re here to guide you through the intricate process of selecting a Cloud ERP platform for your small manufacturing plant.

Understanding Your Unique Manufacturing Needs: The Foundation of Your ERP Journey

Before you even begin to look at specific software solutions, the absolute first step in selecting a Cloud ERP platform for your small manufacturing plant must be a deep dive into your own operations. Every manufacturing plant, regardless of size, has its unique quirks, workflows, and challenges. What are your current pain points? Are you struggling with accurate inventory counts, leading to stockouts or excess inventory? Is your production scheduling a constant juggling act, causing delays and missed deadlines? Are your financial reports always a few weeks behind, making proactive decision-making impossible?

Take the time to map out your core business processes from end to end. This includes everything from how a customer order is received to how raw materials are procured, how products are manufactured, how quality is assured, how products are shipped, and how payments are processed. Involve key stakeholders from different departments – production, finance, sales, purchasing, and even shipping. Their insights are invaluable, as they are the ones who will ultimately be using the system daily. Understanding these specific needs and identifying areas for improvement will create a clear roadmap for what your ideal Cloud ERP system must be able to do. Without this foundational understanding, you risk choosing a system that looks great on paper but doesn’t genuinely solve your unique operational challenges.

Why Cloud ERP? The Modern Advantage for Small Manufacturers

So, you’re convinced you need an integrated system, but why specifically “Cloud” ERP? The shift to the cloud is more than just a buzzword; it represents a fundamental change in how software is delivered and managed. For a small manufacturing plant, the benefits are particularly compelling. Firstly, cloud-based solutions eliminate the need for significant upfront investments in hardware, servers, and IT infrastructure. This dramatically reduces capital expenditure, making powerful ERP accessible even to businesses with tighter budgets. Instead of buying and maintaining physical servers, you pay a predictable monthly or annual subscription fee.

Secondly, accessibility is a huge factor. With a Cloud ERP, your team can access critical business data and functionality from anywhere, at any time, on any device with an internet connection. Imagine your production manager checking schedules from the shop floor on a tablet, or your sales team entering orders while on the road, or even your finance department working remotely if needed. This flexibility fosters collaboration, improves responsiveness, and keeps your operations running smoothly, regardless of location. The ongoing maintenance, updates, and security patches are handled by the vendor, freeing up your internal resources to focus on manufacturing, not IT management. This “hands-off” approach to IT infrastructure is a major draw for small businesses often lacking dedicated, extensive IT departments.

The Hidden Costs of Legacy Systems: Why Staying Put Can Be More Expensive

Many small manufacturing plants cling to older, disparate systems or manual processes, believing it’s the more cost-effective option. However, what they often overlook are the substantial “hidden costs” associated with legacy systems. These aren’t always line items on a budget but manifest as lost productivity, missed opportunities, and increased operational risk. For instance, the time spent manually reconciling data between spreadsheets and accounting software isn’t just inefficient; it’s prone to errors that can lead to costly rework, incorrect inventory, or even compliance issues.

Furthermore, older systems rarely integrate well with modern tools, creating data silos that prevent a holistic view of your business. This lack of real-time visibility means delayed decision-making, an inability to quickly respond to market changes, and ultimately, a loss of competitive edge. Maintaining outdated hardware and software can also become surprisingly expensive, requiring specialized IT support for obscure systems, or facing security vulnerabilities that new software inherently addresses. The initial comfort of sticking with the familiar often evaporates when faced with the tangible and intangible costs of these inefficiencies, making selecting a Cloud ERP platform for your small manufacturing plant a financially sound long-term investment rather than an expense.

Essential Features for Manufacturing Operations: What Your Cloud ERP Must Deliver

When you’re actively selecting a Cloud ERP platform for your small manufacturing plant, the feature set is paramount. While every business has unique needs, certain core manufacturing functionalities are non-negotiable for most small plants aiming for efficiency and growth. First and foremost is Production Planning and Scheduling. This allows you to forecast demand, plan production orders, schedule machines and labor, and track progress against the plan, ensuring you meet delivery dates and optimize resource utilization. Without this, your shop floor can quickly devolve into chaos.

Equally critical is Inventory Management. This feature provides real-time visibility into raw materials, work-in-progress (WIP), and finished goods. It helps you track inventory levels, manage multiple warehouses, perform cycle counts, and optimize reorder points to prevent stockouts while minimizing holding costs. A robust inventory module helps reduce waste, improves cash flow, and ensures you always have the right materials at the right time. Beyond these, look for modules covering Bill of Materials (BOM) for accurate product structuring, Shop Floor Control to track actual production activities, and Quality Management to ensure your products consistently meet specified standards. These features collectively form the backbone of an efficient manufacturing operation.

Financial Management and Accounting Integration: Streamlining Your Books

Beyond the core manufacturing processes, a critical component of any effective ERP system, particularly when selecting a Cloud ERP platform for your small manufacturing plant, is its comprehensive financial management and accounting integration. No business can thrive without a clear understanding of its financial health. A Cloud ERP centralizes all your financial data, providing a unified ledger that encompasses general ledger, accounts payable, accounts receivable, fixed asset management, and even sophisticated reporting tools. This eliminates the need for separate accounting software, reducing manual data entry and minimizing errors that often occur when transferring information between disparate systems.

The integration means that every transaction – from a raw material purchase to a sales order, an invoice payment, or a production run – is automatically reflected in your financial records in real-time. This provides up-to-the-minute visibility into your cash flow, profitability, and overall financial performance. You can generate financial statements like income statements, balance sheets, and cash flow reports with a few clicks, empowering you to make faster, more informed financial decisions. Furthermore, good Cloud ERP platforms offer robust budgeting and forecasting capabilities, helping your small manufacturing plant plan for the future with greater accuracy and confidence.

Supply Chain Management: From Procurement to Delivery Optimization

In today’s globalized economy, a small manufacturing plant’s success is intricately linked to the efficiency of its supply chain. Therefore, when you are selecting a Cloud ERP platform for your small manufacturing plant, its capabilities in supply chain management (SCM) are vital. A comprehensive SCM module will help you manage the entire flow of goods, from sourcing raw materials from your suppliers to delivering finished products to your customers. This includes Procurement Management, automating purchase orders, managing supplier relationships, and tracking incoming goods, often optimizing for cost and lead time.

Beyond procurement, the SCM functionality extends to Warehouse Management, offering tools to efficiently receive, store, pick, pack, and ship goods. This can significantly reduce labor costs, minimize errors, and improve order fulfillment times. Logistics and Shipping Management ensures that your products get to your customers on time and cost-effectively, with features like freight cost calculation and shipment tracking. By integrating these aspects, a Cloud ERP provides end-to-end visibility across your supply chain, allowing you to identify bottlenecks, reduce risks, and respond proactively to disruptions, ultimately enhancing customer satisfaction and boosting your plant’s operational agility.

Customer Relationship Management (CRM) for Manufacturers: Integrating Sales and Service

While often seen as a sales and marketing tool, Customer Relationship Management (CRM) capabilities are increasingly important for manufacturing plants, especially when integrated directly into an ERP system. As you’re selecting a Cloud ERP platform for your small manufacturing plant, consider how CRM functionalities can enhance your customer interactions and drive sales growth. A built-in CRM module allows you to manage all customer data, from initial inquiries and sales leads to order history, support requests, and service contracts, all within a single system.

This integration is invaluable for manufacturers. Your sales team can have real-time access to production schedules and inventory levels, enabling them to provide accurate delivery dates and avoid over-promising. Customer service representatives can quickly access order details, warranty information, and support tickets, leading to faster resolution times and improved customer satisfaction. Furthermore, the data collected within the CRM can be analyzed to identify sales trends, target potential new customers, and improve product offerings based on customer feedback. By breaking down the silos between sales, production, and service, an integrated CRM within your Cloud ERP helps you build stronger customer relationships and drive repeat business, which is crucial for a small manufacturing plant’s sustained growth.

Evaluating Cloud ERP Vendors: Who’s Out There for Small Plants?

Once you have a clear understanding of your internal needs, the next critical step in selecting a Cloud ERP platform for your small manufacturing plant is to research and evaluate potential vendors. The ERP market is vast, but not all solutions are created equal, especially for the unique demands of a small manufacturing operation. You’ll find a spectrum of vendors, from large, well-established players offering robust, industry-specific solutions that might be scaled down for smaller businesses, to niche providers specializing in solutions tailored exclusively for small to medium-sized manufacturing.

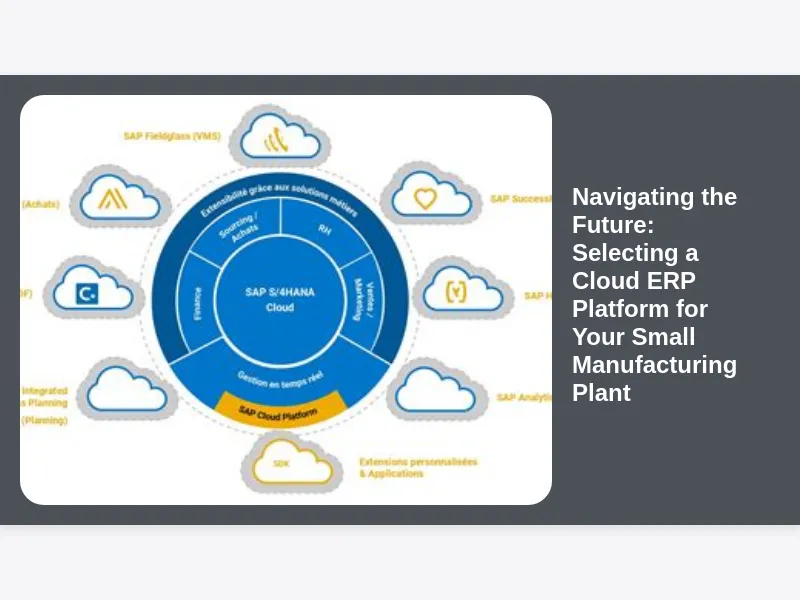

When evaluating vendors, look beyond just the feature list. Consider their industry experience: do they understand the specific challenges and nuances of manufacturing, such as discrete, process, or mixed-mode production? Investigate their reputation for customer support and implementation success, particularly with businesses similar to yours. Request case studies or references from other small manufacturing plants that have implemented their Cloud ERP. Look for vendors who offer transparent pricing models and clear roadmaps for future development. While we won’t name specific products here, widely recognized names like NetSuite, Acumatica, and certain modules from SAP or Oracle often have cloud offerings suitable for scaling down, alongside many specialized manufacturing ERPs designed specifically for SMBs. The key is to find a vendor that aligns with your operational size, industry, and long-term growth aspirations.

The Cloud Advantage: SaaS vs. PaaS vs. IaaS for Your Manufacturing ERP

When discussing “Cloud ERP,” it’s important to understand that the term “cloud” itself encompasses different service models. For most small manufacturing plants, the primary model you’ll encounter and likely leverage when selecting a Cloud ERP platform for your small manufacturing plant is Software-as-a-Service (SaaS). With SaaS ERP, the vendor hosts and manages the entire application, infrastructure, and maintenance. You simply subscribe to the software and access it via a web browser. This is the most popular model because it requires minimal IT overhead from your side, offering the lowest total cost of ownership (TCO) in terms of direct IT expenditure.

While less common for direct ERP consumption, it’s helpful to know about Platform-as-a-Service (PaaS) and Infrastructure-as-a-Service (IaaS). PaaS provides a platform for developers to build, run, and manage applications without the complexity of building and maintaining the infrastructure typically associated with developing and launching an app. IaaS, on the other hand, gives you access to fundamental computing resources like virtual machines, storage, and networks. While a small manufacturing plant might not directly use PaaS or IaaS for their off-the-shelf ERP, a SaaS ERP provider might be leveraging PaaS or IaaS behind the scenes. For your purposes, focus on SaaS, as it delivers the out-of-the-box functionality, ease of deployment, and managed service benefits that are most advantageous for your scale of operations.

Data Security and Compliance: Protecting Your Manufacturing Secrets

One of the most frequent concerns when selecting a Cloud ERP platform for your small manufacturing plant is data security. Moving sensitive business data – including intellectual property, customer lists, financial records, and proprietary manufacturing processes – off-premises and into the cloud naturally raises questions about its safety. Reputable Cloud ERP vendors understand these concerns and invest heavily in robust security measures that often far exceed what a small plant could afford or implement independently. They employ state-of-the-art encryption, multi-factor authentication, regular security audits, intrusion detection systems, and physical security for their data centers.

Beyond security, compliance is another critical consideration. Depending on your industry and location, your small manufacturing plant may need to adhere to various regulatory standards (e.g., FDA for medical devices, ISO certifications, regional data privacy laws like GDPR or CCPA). When evaluating a Cloud ERP, inquire about the vendor’s compliance certifications and how their platform supports your specific regulatory requirements. They should be able to provide documentation and explain their adherence to relevant standards. A trustworthy Cloud ERP vendor will be transparent about their security protocols and compliance measures, giving you peace of mind that your valuable manufacturing data is protected and handled responsibly.

Scalability and Future Growth: Will Your ERP Grow With You?

For any small manufacturing plant, the goal is growth. Therefore, when selecting a Cloud ERP platform for your small manufacturing plant, it’s crucial to choose a solution that can scale alongside your ambitions. An ERP system is a significant investment of time and resources, and you don’t want to outgrow it within a few years, forcing another costly and disruptive implementation. Cloud ERPs are inherently designed for scalability. They allow you to easily add more users, expand into new modules (e.g., adding advanced analytics or a dedicated CRM if you didn’t start with it), or handle increased transaction volumes as your business expands.

This scalability means you’re not locked into a system that was perfect for your current size but will become a bottleneck as you grow. As your product lines diversify, your customer base expands, or you open new production facilities, a good Cloud ERP can adapt to these changes without requiring a complete overhaul. Discuss your growth projections with potential vendors. Ask how their system supports adding new locations, managing complex international transactions (if applicable), or integrating with new technologies as they emerge. A truly scalable Cloud ERP platform acts as an enabler for your growth, not a constraint, ensuring your investment today continues to yield returns tomorrow.

Integration with Existing Systems: A Seamless Transition

While a Cloud ERP aims to be a central nervous system for your manufacturing plant, it’s unlikely to be the only system you use. You might have specialized CAD/CAM software for design, a dedicated IoT platform for machine monitoring, or even specific shipping carrier integrations. Therefore, when selecting a Cloud ERP platform for your small manufacturing plant, assessing its ability to seamlessly integrate with your existing critical systems is a paramount concern. Poor integration can lead to data silos, manual data entry, and negate many of the benefits an ERP promises.

Look for ERP platforms that offer robust Application Programming Interfaces (APIs) or pre-built connectors to common industry-specific software. A strong API strategy allows for two-way data flow, ensuring consistency and accuracy across all your applications. Discuss with vendors how they handle integrations, what tools they provide, and whether they have experience integrating with the specific types of software your plant uses. A well-integrated Cloud ERP platform creates a cohesive technological ecosystem, where data flows freely and automatically between systems, eliminating redundancies and giving you a truly unified view of your operations. This seamless flow is vital for optimizing efficiency and informed decision-making.

Understanding Total Cost of Ownership (TCO): Beyond the Sticker Price

The initial price tag of an ERP system can be deceiving. When selecting a Cloud ERP platform for your small manufacturing plant, it’s crucial to evaluate the Total Cost of Ownership (TCO) rather than just the subscription fees. TCO encompasses all the direct and indirect costs associated with acquiring, implementing, and operating the ERP system over its lifespan, typically three to five years. For Cloud ERP, while the upfront hardware costs are eliminated, other significant cost components remain.

These include:

- Subscription Fees: The recurring monthly or annual cost for the software licenses.

- Implementation Costs: This can be substantial and covers professional services for setup, configuration, data migration, and customization. It’s often billed separately by the vendor or an implementation partner.

- Training Costs: Educating your employees on how to use the new system effectively. This might involve vendor-led training, internal training, or e-learning modules.

- Customization Costs: While Cloud ERPs offer configuration, significant customizations can incur additional development costs and might impact future upgrades.

- Integration Costs: Expenses related to connecting the ERP with your other business-critical software.

- Ongoing Support and Maintenance: Although typically included in SaaS fees, specific premium support or additional services might have extra costs.

- Opportunity Costs: The potential loss of productivity during the transition period or if the system isn’t utilized to its full potential.

Always ask for a detailed breakdown of all potential costs from vendors, and factor in potential internal resource allocation for implementation and ongoing management. A clear understanding of TCO prevents unwelcome financial surprises down the line.

Implementation Strategies: A Phased Approach for Minimal Disruption

Implementing a new ERP system, even a Cloud-based one, is a significant undertaking for any small manufacturing plant. It’s not just a software installation; it’s a business transformation project. When you’re selecting a Cloud ERP platform for your small manufacturing plant, it’s wise to discuss the vendor’s or partner’s recommended implementation strategy. For small businesses, a “big bang” approach, where everything goes live at once, can be overwhelmingly disruptive. A phased implementation strategy is often a more manageable and less risky option.

With a phased approach, you roll out the ERP system module by module or department by department over a period. For example, you might start with financial management and inventory control, then move on to production planning, and finally integrate CRM. This allows your team to gradually adapt to the new system, minimizes immediate disruption to critical operations, and provides opportunities to learn and adjust along the way. Each phase can be thoroughly tested and stabilized before moving to the next. While a phased approach might take longer overall, it significantly reduces risk, improves user adoption, and ensures a smoother transition, which is especially important for a small manufacturing plant that cannot afford prolonged downtime.

Training and User Adoption: Getting Your Team On Board

No matter how sophisticated your chosen Cloud ERP platform is, its success ultimately hinges on how effectively your team uses it. Therefore, when selecting a Cloud ERP platform for your small manufacturing plant, you must place a strong emphasis on training and user adoption. Resistance to change is natural, and inadequate training is a primary reason why ERP implementations fail or deliver suboptimal results. Plan for comprehensive training sessions that are tailored to the specific roles and responsibilities of your employees. A production manager will need different training than an accountant or a sales representative.

Good training should go beyond simply showing users how to click buttons; it should explain why the new system is beneficial and how it will make their jobs easier and more efficient. Consider a “train the trainer” model if you have internal resources capable of becoming power users. Provide ongoing support, create user guides, and establish clear channels for questions and feedback. An engaged team that feels confident and competent using the new ERP will drive its successful adoption, leading to increased productivity, accurate data entry, and a stronger return on your investment. Remember, an ERP is only as good as the people using it.

Data Migration: Moving Your Business’s History Safely

One of the most delicate and critical steps in any ERP implementation is data migration. When you’re selecting a Cloud ERP platform for your small manufacturing plant, you need to understand how your existing data – including customer records, vendor information, product catalogs, historical transactions, inventory levels, and financial statements – will be safely and accurately transferred into the new system. This process is not merely a “copy-paste”; it requires careful planning, cleansing, and validation.

Legacy data often contains inaccuracies, redundancies, or inconsistencies that can corrupt your new system if migrated blindly. Therefore, dedicate resources to data cleansing before migration. Work closely with your chosen ERP vendor or implementation partner to define a clear data migration strategy. This involves identifying which data needs to be migrated, determining the format required by the new system, performing trial migrations, and validating the accuracy of the migrated data. Poor data migration can lead to significant problems down the line, from incorrect financial reports to production errors. Investing time and effort in a meticulous data migration process ensures a clean start with your new Cloud ERP and maintains the integrity of your business information.

Post-Implementation Support and Continuous Improvement

The go-live date for your Cloud ERP is a major milestone, but it’s by no means the end of your ERP journey. In fact, it’s just the beginning. When selecting a Cloud ERP platform for your small manufacturing plant, it’s crucial to consider the post-implementation support offered by the vendor or their partners, and how your plant will approach continuous improvement. Initial weeks and months post-go-live often present new challenges and questions as users fully embrace the system in real-world scenarios. Reliable and responsive support is essential to quickly resolve issues and keep operations running smoothly.

Beyond troubleshooting, think about how you will continue to optimize your ERP usage. Cloud ERPs typically receive regular updates and new features from vendors. How will you stay informed and leverage these enhancements? Establish a process for regularly reviewing your ERP’s performance, identifying areas for further optimization, and perhaps exploring additional modules as your business needs evolve. A successful Cloud ERP implementation fosters a culture of continuous improvement, where your plant constantly seeks ways to refine processes, extract more value from the system, and adapt to changing market conditions. This long-term perspective ensures your ERP remains a strategic asset for years to come.

Making the Final Decision: A Checklist for Your Cloud ERP Platform Selection

You’ve done your homework, mapped your processes, evaluated vendors, and considered all the critical factors. Now it’s time for the ultimate step: making the final decision in selecting a Cloud ERP platform for your small manufacturing plant. To consolidate your thoughts, use a comprehensive checklist.

Here are the key questions to ask yourself and your team before signing on the dotted line:

- Needs Alignment: Does the chosen ERP truly address your core manufacturing pain points and align with your business objectives? Does it cover all essential modules from production to finance?

- Industry Fit: Does the vendor have proven experience with small manufacturing plants in your specific industry (e.g., discrete, process, make-to-order)?

- Scalability: Can the system comfortably scale with your anticipated growth over the next 5-10 years without requiring a complete re-implementation?

- Security & Compliance: Are the vendor’s security protocols robust, and do they meet your industry’s regulatory compliance requirements?

- Integration Capabilities: Will it seamlessly integrate with your existing critical software (CAD, IoT, shipping, etc.)?

- Total Cost of Ownership (TCO): Have you accounted for all costs – subscriptions, implementation, training, support, and potential customizations – over the long term? Is it within your budget?

- Implementation & Support: Does the vendor or partner offer a clear implementation plan (preferably phased for SMBs) and reliable post-go-live support?

- User Experience: Is the interface intuitive and user-friendly, minimizing the learning curve for your employees? Have you conducted demos with actual users?

- Vendor Reputation & Stability: Is the vendor financially stable and committed to long-term development of their Cloud ERP platform? What do their customer references say?

- References: Have you spoken to other small manufacturing plants that have implemented this specific solution? Their insights are invaluable.

Taking a deliberate, measured approach to these questions will significantly increase your chances of successfully selecting a Cloud ERP platform for your small manufacturing plant that truly transforms your operations and sets you up for future success. This isn’t just a software purchase; it’s a strategic investment in your plant’s future.

Future-Proofing Your Manufacturing Operations with Cloud ERP

The manufacturing world is in constant flux, driven by technological advancements like Industry 4.0, IoT, AI, and increasingly complex supply chains. When you are selecting a Cloud ERP platform for your small manufacturing plant, you are not just solving today’s problems; you are making a strategic investment to future-proof your operations. A modern Cloud ERP, by its very nature, is designed to be agile and adaptable. It allows you to embrace new technologies and methodologies without ripping and replacing your core system every few years.

Cloud vendors continuously update their platforms, often incorporating emerging technologies and best practices into their regular releases. This means your small plant benefits from cutting-edge features that might have been out of reach just a few years ago. The flexibility of a modular cloud system means you can gradually adopt new capabilities – perhaps adding advanced analytics, machine learning for predictive maintenance, or even robotic process automation – as your business matures and market demands evolve. By choosing a forward-thinking Cloud ERP, you ensure your small manufacturing plant remains competitive, innovative, and resilient against future disruptions, ready to seize new opportunities as they arise.

Choosing the Right ERP Partner: More Than Just a Vendor

While the ERP software itself is critical, the partner you choose to help you implement and support it is equally, if not more, important, especially when selecting a Cloud ERP platform for your small manufacturing plant. For many small businesses, direct implementation from the software vendor can be expensive or less personalized. This is where an experienced implementation partner comes in. A good ERP partner doesn’t just sell you software; they act as a trusted advisor who understands your industry, your specific business processes, and your goals.

Look for a partner with a proven track record of successful implementations for small manufacturing plants. They should have certified consultants who are experts in the specific Cloud ERP platform you’re considering. A strong partner will guide you through every stage, from initial needs assessment and system configuration to data migration, user training, and post-go-live support. They can help you customize the system to your unique workflows (within the limits of cloud best practices), troubleshoot issues, and ensure you maximize your return on investment. The relationship with your ERP partner will be long-term, so choose one whose values, communication style, and support model align well with your business culture. They are your essential bridge to a successful ERP transformation.

Customization Options: Balancing Specific Needs with Cloud Standards

Every small manufacturing plant believes it has unique processes, and often, they’re right. This leads to the question of customization when selecting a Cloud ERP platform for your small manufacturing plant. Traditionally, on-premise ERPs allowed for extensive, deep customizations. However, Cloud ERP (SaaS) platforms, by design, prioritize standardization to enable easier updates and lower maintenance costs. This doesn’t mean you can’t tailor the system, but the approach to customization is different.

Most modern Cloud ERPs offer robust configuration tools. This means you can adjust workflows, add custom fields, create custom reports, and modify user interfaces without altering the core code. This “configuration over customization” approach is generally recommended for cloud solutions, as it ensures your system remains easily upgradable and avoids potential compatibility issues with future vendor releases. If your plant has truly unique processes that cannot be handled by configuration, discuss these specific needs with potential vendors and partners. They might suggest using APIs to integrate specialized external tools or building minor, carefully managed extensions. The goal is to find a balance: adopt industry best practices where possible, configure the system to meet your specific needs, and only pursue customizations as a last resort, always understanding their potential long-term implications for upgrades and support.

Reporting and Analytics Capabilities: Gaining Actionable Insights

One of the most powerful benefits of a well-implemented Cloud ERP system for a small manufacturing plant is its ability to transform raw data into actionable insights. When selecting a Cloud ERP platform for your small manufacturing plant, pay close attention to its reporting and analytics capabilities. A unified system consolidates data from production, inventory, sales, and finance, allowing you to generate comprehensive reports that were previously impossible or incredibly time-consuming to compile manually.

Imagine easily tracking production yields, identifying cost drivers, analyzing sales trends by product line, or monitoring supplier performance in real-time. Good Cloud ERPs offer pre-built reports for common manufacturing and financial metrics, but also provide tools for creating custom reports and dashboards. Look for drag-and-drop interfaces, drill-down capabilities, and visual data representations (charts, graphs) that make complex information easy to understand. Some advanced systems even incorporate business intelligence (BI) features or integrate with external BI tools, allowing for deeper predictive analytics. These insights empower you to make data-driven decisions, optimize processes, identify new opportunities, and ultimately drive greater profitability and efficiency for your small manufacturing plant.

Mobile Access for Manufacturing Teams: Productivity On The Go

In today’s fast-paced environment, static workstations are increasingly a thing of the past. Your manufacturing plant and its team are dynamic, requiring access to information from various locations, whether on the shop floor, in the warehouse, or out on a sales call. Therefore, when selecting a Cloud ERP platform for your small manufacturing plant, robust mobile access capabilities are a significant advantage and often a necessity. Mobile access allows your employees to stay connected and productive, regardless of their physical location.

Imagine a shop floor manager using a tablet to update production statuses, track material consumption, or perform quality checks in real-time, right from the manufacturing line. Or a warehouse supervisor using a smartphone to conduct inventory counts, receive goods, or manage shipments. Sales teams can access customer order history, check inventory availability, and submit new orders while visiting clients. Cloud ERPs are inherently accessible via web browsers, but many also offer dedicated mobile apps optimized for smartphones and tablets. These apps often feature simplified interfaces and offline capabilities, enhancing user experience and productivity. Providing your team with mobile access to key ERP functions boosts efficiency, improves data accuracy, and fosters a more responsive and agile manufacturing operation.

Compliance and Regulatory Requirements: Staying Within the Lines

For many small manufacturing plants, operating within a framework of compliance and regulatory requirements is not just good practice, it’s mandatory. Whether it’s adherence to industry-specific standards (e.g., FDA, ISO, AS9100), environmental regulations, or financial reporting standards, these rules dictate how you operate and how your data is managed. Therefore, when selecting a Cloud ERP platform for your small manufacturing plant, it is absolutely critical to verify its capabilities in supporting your compliance needs. Failure to comply can result in hefty fines, reputational damage, and even operational shutdowns.

Discuss your specific compliance requirements with potential ERP vendors. Ask how their system helps you track and document quality processes, manage batches and serial numbers for traceability, maintain audit trails for financial transactions, or generate reports that satisfy regulatory bodies. For instance, if you require lot tracking or expiration date management for your products, ensure the ERP system can handle these specific functionalities. A robust Cloud ERP should provide features that simplify the process of demonstrating compliance, such as comprehensive reporting, secure data storage, and controlled access. Choosing an ERP that understands and supports your regulatory landscape will save you significant headaches and costs in the long run, allowing you to focus on manufacturing with confidence.