Embarking on a journey to implement an Enterprise Resource Planning (ERP) system in a small manufacturing business is a bold and strategic move. It promises a future of streamlined operations, enhanced productivity, and greater control over every facet of production, from raw materials to final delivery. However, the path to achieving these benefits is often riddled with complexities, unique hurdles that can trip up even the most enthusiastic small manufacturer. The allure of digital transformation is strong, but the reality of Overcoming Implementation Challenges for Small Manufacturing ERP requires careful planning, unwavering commitment, and a deep understanding of potential pitfalls. This comprehensive guide aims to arm you with the knowledge and strategies needed to navigate these obstacles, ensuring your ERP investment truly pays off.

The Strategic Imperative: Why Small Manufacturers Need ERP

In today’s fast-paced global economy, small manufacturing businesses face immense pressure to compete with larger enterprises while maintaining agility and responsiveness. Manual processes, disparate spreadsheets, and siloed data simply can no longer cut it. This is where an ERP system becomes not just an advantage, but a strategic imperative. By integrating core business processes like production, inventory, sales, purchasing, and finance into a single, unified system, ERP provides a holistic view of operations, empowering small manufacturers to make data-driven decisions, reduce waste, and improve customer satisfaction.

Many small manufacturers initially hesitate, fearing the cost and complexity associated with ERP. However, modern ERP solutions, particularly those designed for smaller enterprises, offer scalable and affordable options that bring sophisticated capabilities within reach. The true value lies in the ability to eliminate bottlenecks, optimize resource utilization, and foster a culture of efficiency, all of which directly impact the bottom line and long-term sustainability. Without a robust system to manage their intricate processes, these businesses risk falling behind, losing their competitive edge in an increasingly digital world.

Decoding Small Manufacturing ERP: Tailored for Agility

Understanding what constitutes “small manufacturing ERP” is crucial because it isn’t simply a scaled-down version of an enterprise-level system. Instead, it’s typically designed with the specific needs and constraints of smaller operations in mind. This means focusing on ease of use, rapid deployment, and functionalities most critical for production, such as bill of material (BOM) management, shop floor control, inventory optimization, and basic financial reporting, without the overwhelming complexity of modules a large multinational might require.

These tailored solutions often come with industry-specific templates and best practices built-in, reducing the need for extensive customization and speeding up the implementation process. Cloud-based ERP offerings have further revolutionized access for small manufacturers, significantly lowering upfront infrastructure costs and allowing businesses to pay for what they use. This agility in both features and deployment models makes small manufacturing ERP an increasingly attractive and viable option for companies looking to modernize their operations without breaking the bank or getting bogged down in an overly complex system.

The Promise of Transformation Versus the Pitfalls of Execution

The vision of a fully integrated, highly efficient manufacturing operation fueled by an ERP system is undeniably compelling. Imagine real-time visibility into inventory levels, accurate production scheduling that adapts to demand, and seamless financial reconciliation. This promise of digital transformation is the primary driver for many small manufacturers contemplating an ERP investment. It offers the potential to move beyond reactive decision-making to proactive strategic planning, allowing businesses to anticipate challenges and seize opportunities with greater confidence.

However, between this inspiring vision and the tangible reality lies a chasm often filled with unexpected challenges. Many small businesses, while eager for the benefits, underestimate the internal resources, time, and strategic foresight required to successfully implement such a system. The pitfalls are numerous and varied, ranging from technical difficulties and data migration nightmares to human resistance and budget overruns. Navigating this treacherous landscape without a clear roadmap can transform a promising investment into a costly, demoralizing failure. It’s imperative to approach this journey with open eyes, acknowledging that Overcoming Implementation Challenges for Small Manufacturing ERP demands a robust, multifaceted strategy.

Identifying Common Implementation Obstacles in Small Manufacturing

While every ERP journey is unique, certain obstacles tend to recur for small manufacturing businesses. These often stem from a combination of limited resources, entrenched manual processes, and a lack of prior experience with large-scale system deployments. Common issues include an unclear understanding of the project’s scope, underestimation of the time and effort required, and a failure to adequately prepare the workforce for significant change. These challenges, if not addressed proactively, can derail the entire implementation process, leading to delays, cost overruns, and ultimately, a system that fails to deliver on its promised value.

Other frequent stumbling blocks involve the quality of existing data, the complexity of integrating the new ERP with legacy systems, and the difficulty in selecting an ERP vendor that truly understands the nuances of small-scale manufacturing. These obstacles are not insurmountable, but they demand a strategic approach, meticulous planning, and a willingness to adapt. Recognizing these common pitfalls early is the first critical step in developing a robust strategy for Overcoming Implementation Challenges for Small Manufacturing ERP. By understanding where others have struggled, you can better prepare your own organization for a smoother, more successful transition.

Challenge 1: Lack of Clear Project Scope and Objectives

One of the most insidious yet common challenges for small manufacturers adopting ERP is the failure to clearly define the project’s scope and objectives from the outset. Without a precise understanding of what the ERP system is meant to achieve, which problems it will solve, and what success looks like, the project can quickly lose direction. Ambiguous goals lead to scope creep, where additional features or functionalities are requested midway through, inflating costs and extending timelines unnecessarily. This lack of clarity can also create friction between departments, as each might have different expectations for the new system.

To mitigate this, it’s paramount to invest significant time upfront in a detailed discovery phase. This involves meticulously documenting current processes, identifying inefficiencies, and prioritizing the pain points that the ERP system must address. Engaging key stakeholders from across the organization – from the shop floor to the sales office – ensures that a comprehensive and realistic set of objectives is established. A well-defined scope acts as a guiding star, keeping the project focused and aligned with the strategic goals of the small manufacturing business. Without this foundational clarity, Overcoming Implementation Challenges for Small Manufacturing ERP becomes an uphill battle against shifting sands.

Challenge 2: Inadequate Resource Allocation (Time, Budget, Personnel)

Small manufacturing businesses, by their very nature, often operate with lean teams and tight budgets. This reality frequently translates into inadequate resource allocation for an ERP implementation, a mistake that can prove incredibly costly in the long run. Underestimating the time commitment required from internal staff for data preparation, training, and testing is a common pitfall. Expecting employees to manage their regular duties and take on significant ERP project responsibilities simultaneously often leads to burnout, project delays, and a rushed, suboptimal deployment.

Similarly, under-budgeting for critical aspects like software licensing, customization (if truly necessary), data migration tools, training programs, and potential consulting fees can cripple the project. Many small manufacturers focus solely on the software cost, overlooking the substantial “soft costs” associated with successful implementation. Furthermore, not dedicating key personnel, even part-time, to champion the project and coordinate internal efforts can leave the implementation without vital internal leadership. A realistic assessment of the financial, human, and time resources required is not merely a suggestion; it’s a non-negotiable prerequisite for Overcoming Implementation Challenges for Small Manufacturing ERP.

Challenge 3: Resistance to Change and User Adoption Hurdles

Human nature often dictates a preference for the familiar, even if the familiar is inefficient. For a small manufacturing team accustomed to established routines, manual processes, and perhaps even their own idiosyncratic ways of managing data, the introduction of a new ERP system can feel disruptive, threatening, and overwhelming. This inherent resistance to change is a significant hurdle to user adoption, and if not addressed proactively and empathetically, it can sabotage the entire ERP investment. Employees may fear job displacement, the need to learn new skills, or simply the discomfort of stepping outside their comfort zones.

Successful Overcoming Implementation Challenges for Small Manufacturing ERP hinges critically on robust change management strategies. This begins with transparent communication from leadership, explaining why the ERP is being implemented, how it will benefit individuals and the company, and what the transition process will look like. Involving employees in the planning stages, soliciting their input, and demonstrating how the new system will alleviate their pain points can transform skepticism into engagement. Providing ample training, ongoing support, and celebrating early wins are also vital to fostering a positive attitude and ensuring high user adoption rates, turning potential resisters into enthusiastic advocates.

Challenge 4: Data Migration Headaches and Data Quality Issues

The heart of any ERP system is its data. Production schedules, inventory records, customer orders, supplier information, and financial figures all need to be accurate, consistent, and readily accessible. However, for many small manufacturers, this critical data resides in fragmented spreadsheets, outdated legacy systems, or even physical ledgers, often plagued by inconsistencies, duplications, and inaccuracies. The process of extracting, cleaning, transforming, and loading this data into the new ERP system – known as data migration – is one of the most technically demanding and time-consuming aspects of implementation.

Poor data quality can render even the most sophisticated ERP system ineffective. If the data going in is flawed, the insights coming out will be equally unreliable, eroding trust in the new system. Small manufacturers must dedicate significant effort to data cleansing before migration, establishing clear data governance policies for the future. This often involves tedious manual work, but shortcuts here inevitably lead to more significant problems down the line. A strategic approach to data migration, perhaps with the help of specialized tools or consultants, is essential for Overcoming Implementation Challenges for Small Manufacturing ERP and ensuring the new system starts with a solid, trustworthy foundation.

Challenge 5: Customization Pitfalls Versus Best Practices Adoption

One of the tempting yet dangerous traps for small manufacturers implementing ERP is the desire to heavily customize the software to perfectly mimic existing, often inefficient, processes. While some level of configuration is usually necessary to align the system with unique business requirements, excessive customization introduces complexity, increases implementation costs and timelines, and makes future upgrades significantly more difficult and expensive. It can also negate the benefits of adopting industry best practices that are often embedded within standard ERP functionalities.

The smarter approach for small manufacturing businesses is to prioritize adopting the ERP system’s standard best practices wherever possible, adapting their internal processes to fit the software rather than the other way around. This requires a willingness to re-evaluate and potentially re-engineer existing workflows. When customization is truly unavoidable, it should be thoroughly justified, meticulously documented, and kept to a minimum. A balance must be struck between the unique needs of the business and the long-term maintainability and cost-effectiveness of a less customized solution. Thoughtful decision-making here is paramount for Overcoming Implementation Challenges for Small Manufacturing ERP successfully.

Challenge 6: The Critical Task of Vendor Selection Woes

Choosing the right ERP vendor and software is perhaps the single most important decision in the entire implementation journey. For small manufacturing businesses, this choice is often fraught with anxiety, given the sheer number of solutions available and the significant investment involved. Many vendors cater primarily to larger enterprises, and their offerings may be overly complex or expensive for a smaller operation. Conversely, some smaller vendors might lack the necessary industry expertise or long-term support capabilities.

A haphazard vendor selection process, based solely on price or a flashy demo, can lead to costly mismatches. Small manufacturers must conduct thorough due diligence, clearly defining their requirements, researching vendors with a proven track record in their specific industry, and evaluating not just the software’s features but also the vendor’s implementation methodology, support services, and future roadmap. Engaging in detailed discussions, requesting references, and even piloting modules can provide invaluable insights. The right partnership can make Overcoming Implementation Challenges for Small Manufacturing ERP significantly smoother, while the wrong one can turn it into a nightmare.

Challenge 7: Insufficient Training and Ongoing User Support

Even the most perfectly implemented ERP system will fail if users are not adequately trained and supported. For small manufacturing teams, who often wear multiple hats, finding dedicated time for training can be difficult, and a “learn-as-you-go” approach is tempting but rarely effective. Insufficient training leads to frustration, errors, low adoption rates, and a failure to fully leverage the system’s capabilities. If employees don’t feel confident and competent using the new tools, they will revert to old methods or find workarounds, undermining the entire investment.

Effective training goes beyond a single session; it involves a continuous process tailored to different user roles and learning styles. Hands-on exercises, real-world scenarios, and access to comprehensive user manuals and quick-reference guides are crucial. Furthermore, ongoing support, whether through internal champions, a dedicated help desk, or readily available online resources, is vital for addressing questions and issues as they arise post-go-live. Investing in robust training and support mechanisms is not an optional extra; it is a fundamental pillar for Overcoming Implementation Challenges for Small Manufacturing ERP and ensuring the long-term success of the system.

Challenge 8: Integration Complexities with Existing Systems

While a core promise of ERP is integration, the reality for many small manufacturers is a patchwork of existing, often disparate, systems. This might include specialized CAD/CAM software, shop floor control systems, CRM platforms, or even older accounting packages that cannot be immediately replaced. Integrating these legacy systems with the new ERP can be a complex technical challenge, requiring custom interfaces, data mapping, and extensive testing to ensure seamless data flow and process synchronization.

Failing to properly plan for these integrations can lead to data inconsistencies, operational bottlenecks, and a fragmented view of the business, negating many of the benefits an ERP system is supposed to provide. Small manufacturers need to thoroughly audit their existing IT landscape, identify critical integration points, and discuss these requirements in detail with potential ERP vendors. Prioritizing essential integrations and carefully phasing in more complex ones can help manage this challenge. A strategic approach to managing integration complexities is paramount for Overcoming Implementation Challenges for Small Manufacturing ERP and creating a truly unified operational environment.

Strategic Planning for Successful ERP Deployment

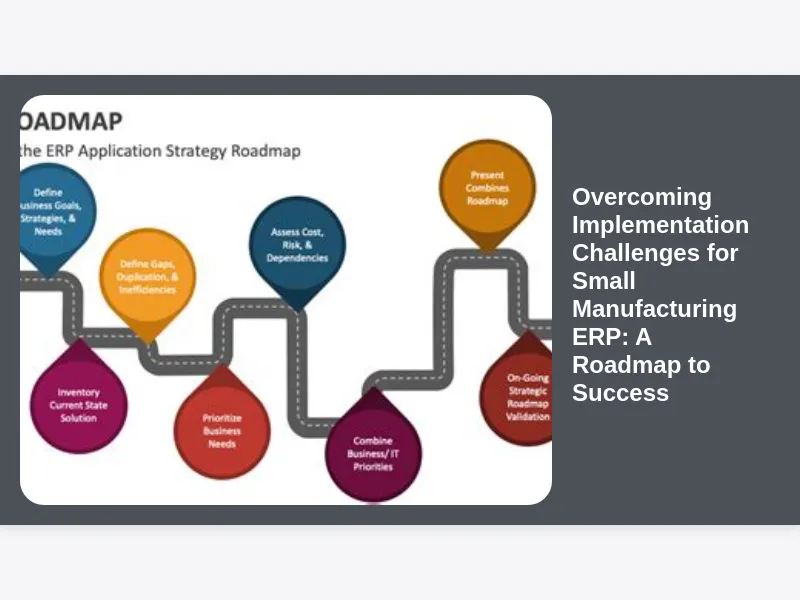

The foundation of successfully Overcoming Implementation Challenges for Small Manufacturing ERP lies in meticulous and strategic planning. This isn’t just about selecting software; it’s about reimagining your entire operational landscape. A comprehensive plan should outline a clear project roadmap, including specific milestones, deadlines, and responsibilities for each phase. It must encompass a detailed assessment of current processes, a vision for future state processes, and a gap analysis identifying where the ERP needs to bridge those gaps.

Beyond the technical aspects, strategic planning also includes crucial elements like change management strategies, communication plans, and a robust risk assessment matrix. Anticipating potential problems and having contingency plans in place can prevent minor setbacks from escalating into major crises. Small manufacturers should allocate dedicated time and resources to this planning phase, recognizing that the effort invested upfront will significantly reduce headaches and ensure a smoother journey towards a successful ERP deployment. Skipping or rushing this crucial step is a common error that undermines the entire project.

Building a Dedicated Internal Project Team

While external consultants and vendor teams play a vital role, the sustained success of an ERP implementation for a small manufacturing business heavily relies on a dedicated and empowered internal project team. This team acts as the bridge between the external experts and the internal users, ensuring that the system is configured to meet specific business needs and that employees are ready to adopt it. The team should be cross-functional, representing all key departments that will interact with the ERP, including production, inventory, sales, finance, and IT (if applicable).

Leadership within this team is critical. A designated project manager, ideally with a strong understanding of both manufacturing processes and project management principles, will be essential for keeping the project on track, managing communications, and resolving internal conflicts. Members of this team will be responsible for defining requirements, participating in testing, championing change, and eventually becoming internal experts who can support their colleagues. Empowering this team and providing them with the necessary time and resources are non-negotiable aspects of Overcoming Implementation Challenges for Small Manufacturing ERP and fostering long-term system ownership.

Embracing Agile Methodologies for ERP Implementation

Traditionally, ERP implementations followed a rigid “big bang” approach, attempting to deploy the entire system at once. While this can work for some, for small manufacturing businesses, the risks are often too high, and the upfront investment too daunting. An increasingly popular and effective strategy for Overcoming Implementation Challenges for Small Manufacturing ERP is to embrace agile methodologies. This involves breaking the implementation into smaller, manageable phases or modules, allowing for incremental deployment and continuous feedback.

By implementing the ERP in stages – perhaps starting with inventory and purchasing, then moving to production, and finally finance – small manufacturers can realize benefits sooner, reduce the overall risk, and adapt the system based on real-world usage and feedback. This iterative approach allows for greater flexibility, quicker course corrections, and less disruption to daily operations. It also helps build confidence and momentum within the organization as users see tangible results and become more comfortable with the new system step by step, making the transition feel less overwhelming.

The Role of Expert Consultants in ERP Success

For small manufacturing businesses, internal expertise in large-scale system implementation is often limited. This is where engaging experienced ERP consultants becomes invaluable. A good consultant brings not only deep technical knowledge of the ERP software but also a wealth of experience from similar projects in the manufacturing sector. They can provide unbiased advice, help navigate complex decisions, and guide the internal team through each phase of the implementation, from initial planning to post-go-live support.

Consultants can play various roles, from project management and change management to data migration and user training. They help define realistic expectations, identify potential risks, and ensure that best practices are followed. While engaging consultants represents an additional cost, their expertise often prevents costly mistakes, accelerates the implementation timeline, and significantly increases the chances of a successful outcome. For Overcoming Implementation Challenges for Small Manufacturing ERP, viewing consultants not as an expense, but as a strategic investment in expertise, can be a game-changer. [Link to an article on "Choosing an ERP Consultant for Small Businesses"]

Post-Implementation Support and Continuous Improvement

The “go-live” date for an ERP system is not the finish line; it’s merely the end of the beginning. Many small manufacturers make the mistake of believing that once the system is live, the work is done. In reality, the post-implementation phase is critical for realizing the full value of the investment and truly Overcoming Implementation Challenges for Small Manufacturing ERP in the long term. This period is often characterized by a “dip” in productivity as users fully adapt, encounter unforeseen issues, and learn the nuances of the new system.

Robust post-implementation support is essential. This includes clear channels for users to report bugs or ask questions, prompt resolution of issues, and ongoing access to training and refresher courses. Furthermore, an ERP system should be viewed as a living tool that requires continuous improvement. Regularly reviewing system performance, gathering user feedback, and identifying opportunities for optimization will ensure that the ERP continues to evolve with the business and deliver maximum value over time. Establishing internal champions and a process for ongoing system review ensures the ERP remains a strategic asset.

Measuring ROI and Long-Term Benefits

Justifying the significant investment in an ERP system requires a clear understanding of its return on investment (ROI) and the long-term benefits it delivers. For small manufacturing businesses, quantifying these can sometimes be challenging, but it’s essential for proving the value of the implementation and securing future buy-in for system enhancements. Before implementation, clear key performance indicators (KPIs) related to the project’s objectives should be established. These might include reductions in inventory holding costs, improvements in on-time delivery, decreased production errors, faster order fulfillment, or more accurate financial reporting.

After go-live, these KPIs should be regularly monitored and compared against baseline data. Beyond financial metrics, the long-term benefits often extend to improved data accuracy, enhanced decision-making capabilities, greater operational transparency, and increased employee morale due to reduced manual drudgery. Documenting these tangible and intangible benefits not only validates the initial investment but also provides a compelling case for ongoing commitment to the ERP system as a core strategic tool for Overcoming Implementation Challenges for Small Manufacturing ERP and driving sustainable growth. [Link to a resource on "Calculating ERP ROI for Small Manufacturers"]

Future-Proofing Your Small Manufacturing ERP System

The manufacturing landscape is constantly evolving, driven by technological advancements like AI, IoT, and advanced analytics. For a small manufacturing ERP system to remain a valuable asset, it must be future-proofed against obsolescence. This means considering scalability, flexibility, and the vendor’s commitment to ongoing innovation when making the initial selection. Can the system grow with your business as you expand production, add new product lines, or enter new markets? Can it easily integrate with emerging technologies without requiring a complete overhaul?

Cloud-based ERP solutions often offer a distinct advantage here, as updates and new features are typically rolled out automatically by the vendor, ensuring the system remains current and secure. Additionally, choosing a modular ERP allows for the gradual adoption of new functionalities as business needs evolve. Proactively planning for future growth and technological shifts ensures that your ERP system remains a dynamic and relevant tool for years to come, consistently contributing to Overcoming Implementation Challenges for Small Manufacturing ERP and securing your competitive position.

Conclusion: A Strategic Journey Towards Manufacturing Excellence

The decision to implement an ERP system is one of the most transformative steps a small manufacturing business can take. While the journey is undeniably fraught with potential hurdles, the rewards of streamlined operations, enhanced productivity, and data-driven decision-making are well worth the effort. Overcoming Implementation Challenges for Small Manufacturing ERP is not about avoiding problems entirely, but about anticipating them, planning meticulously, and responding strategically. It demands leadership commitment, a dedicated internal team, robust change management, and a willingness to embrace new ways of working.

By focusing on clear objectives, allocating sufficient resources, prioritizing data quality, embracing best practices, and investing in continuous training and support, small manufacturers can successfully navigate the complexities of ERP deployment. The right vendor, a phased implementation approach, and the judicious use of expert consultants can further smooth the path. Ultimately, a successful ERP implementation is a strategic journey that empowers small manufacturing businesses to achieve operational excellence, drive sustainable growth, and confidently face the challenges of tomorrow’s competitive landscape. Your investment in an ERP system is an investment in your future, paving the way for greater efficiency and unparalleled control over your manufacturing destiny.