In the bustling world of manufacturing, even the slightest misstep can ripple through the entire production line, leading to costly errors, delays, and dissatisfied customers. For small-scale production facilities, where every resource counts and margins are often tighter, reducing production errors with Cloud ERP for small-scale production isn’t just a goal; it’s an absolute necessity for survival and growth. This isn’t about simply patching up problems as they arise; it’s about building a resilient, efficient operation from the ground up, and that’s precisely where a robust Cloud ERP system steps in as your most valuable ally.

Imagine a manufacturing process where information flows seamlessly, where every material, every machine, and every human action is tracked, optimized, and contributes to a perfect final product. This vision, once reserved for enterprise giants with vast IT budgets, is now entirely accessible to small-scale producers thanks to the power and flexibility of cloud-based Enterprise Resource Planning. This article will delve deep into how Cloud ERP transforms your small operation, systematically dismantling the common culprits of production errors and paving the way for unprecedented precision and profitability.

The Silent Cost of Production Errors in Manufacturing

Production errors, though sometimes unseen until a finished product fails inspection, carry a heavy and often underestimated price tag. These aren’t just minor inconveniences; they erode profits, damage reputations, and can even stunt the growth potential of an otherwise promising small-scale business. Understanding the multifaceted impact of these errors is the first step toward recognizing the urgent need for a solution like Cloud ERP.

Beyond the obvious financial hits from scrapped materials or extensive rework, errors consume invaluable time—time that could be spent on innovation, market expansion, or simply fulfilling more orders. Every minute spent troubleshooting a manufacturing defect is a minute lost from productive activity, contributing to missed deadlines and a decrease in overall operational efficiency. It’s a cumulative burden that can slowly, but surely, undermine a company’s competitive edge and long-term viability in a demanding marketplace.

Errors also have a profound impact on team morale. Constantly battling mistakes, redoing tasks, and dealing with customer complaints can lead to frustration, burnout, and a sense of futility among employees. This can, in turn, lead to higher turnover rates, further exacerbating the problem as institutional knowledge is lost and new team members need to be trained, often inheriting the same flawed processes that caused the initial errors. A cycle of inefficiency and dissatisfaction becomes entrenched, making it even harder to break free without a significant intervention.

Moreover, the reputational damage from recurring production errors can be catastrophic, particularly for small businesses that rely heavily on word-of-mouth and customer loyalty. A single batch of faulty products can lead to negative reviews, loss of customer trust, and a tarnished brand image that takes years, if not decades, to rebuild. In today’s interconnected world, where information spreads rapidly, maintaining a sterling reputation for quality and reliability is paramount, making reducing production errors with Cloud ERP for small-scale production not just a luxury, but a strategic imperative.

Why Small-Scale Production Faces Unique Challenges

Small-scale production, while agile and often innovative, inherently faces a unique set of challenges that make it particularly susceptible to production errors. Unlike larger enterprises with dedicated departments and extensive resources, small manufacturers often operate with lean teams, multi-hatted employees, and limited capital for advanced technological investments. These constraints can inadvertently create an environment where errors are more likely to occur and harder to detect and rectify.

One of the most significant hurdles is the reliance on manual processes and disparate systems. Many small businesses track inventory on spreadsheets, manage orders via email, and rely on human memory for production schedules. This fragmentation of information is a breeding ground for inconsistencies: a misplaced decimal in an order form, an outdated inventory count, or a forgotten step in a manufacturing sequence can all lead to errors that are difficult to trace back to their origin. The lack of a centralized data hub means critical insights are scattered, making proactive problem-solving nearly impossible.

Limited access to real-time data further complicates matters. Without an integrated system that captures data as it happens on the shop floor, managers are often making decisions based on outdated or incomplete information. This reactive approach means errors are usually discovered after they’ve already caused damage, rather than being prevented in the first place. For instance, a machine malfunction might go unnoticed until it produces a significant number of defective units, by which time valuable materials and labor have already been wasted.

Furthermore, small-scale operations often lack the dedicated quality assurance teams or sophisticated inspection equipment found in larger companies. Quality checks might be performed intermittently or by production staff who are already burdened with multiple responsibilities, increasing the chance of overlooking defects. The pressure to meet tight deadlines with limited resources can also lead to shortcuts that compromise quality, making reducing production errors with Cloud ERP for small-scale production an essential strategy to overcome these inherent operational vulnerabilities.

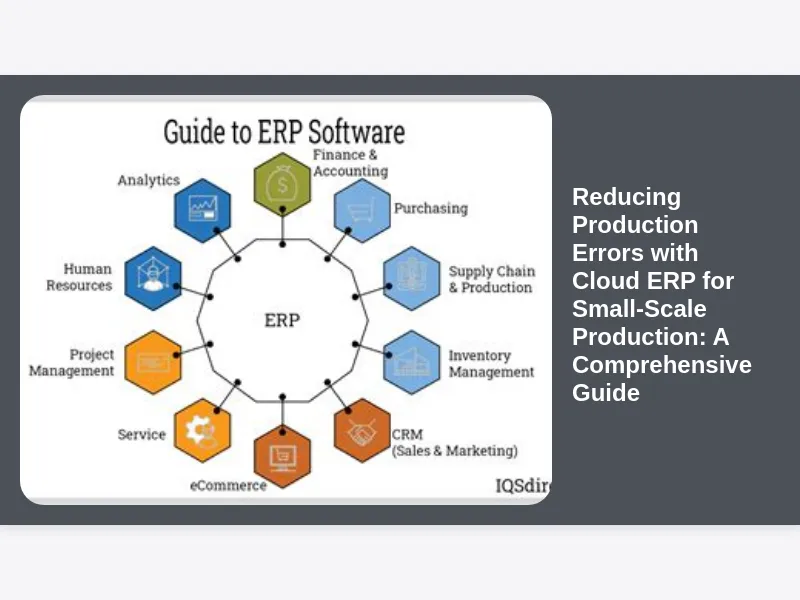

Understanding Cloud ERP: A Game-Changer for Small Manufacturers

For many small manufacturers, the term “ERP” might conjure images of complex, expensive software implementations suited only for multi-national corporations. However, the advent of Cloud ERP has dramatically shifted this paradigm, making sophisticated resource planning accessible, affordable, and incredibly powerful for businesses of all sizes, especially those in small-scale production. It’s not just a software; it’s a comprehensive business management solution hosted on the internet.

At its core, Cloud ERP integrates all facets of your business – from inventory management and procurement to production planning, sales, and customer service – into a single, unified system. Instead of maintaining disparate databases and relying on manual data transfer between departments, everything lives in one central location, accessible securely from anywhere with an internet connection. This real-time visibility is revolutionary for small-scale operations, eliminating information silos and ensuring everyone is working from the same, most current data set.

The “cloud” aspect is what truly differentiates it and makes it a game-changer for smaller businesses. Unlike traditional on-premise ERP systems that require significant upfront investment in hardware, software licenses, and dedicated IT staff for maintenance, Cloud ERP operates on a subscription model. This “Software-as-a-Service” (SaaS) approach means lower initial costs, predictable monthly expenses, and no need to worry about server maintenance, backups, or software updates – all handled by the ERP provider. This frees up valuable capital and resources that small manufacturers can reinvest into their core operations.

Crucially, Cloud ERP solutions are designed with scalability and flexibility in mind, which is perfect for growing small-scale production businesses. As your production volume increases, your customer base expands, or you introduce new product lines, your ERP system can easily adapt without requiring a complete overhaul. This agility allows small manufacturers to remain competitive, quickly respond to market changes, and continuously optimize their operations, laying a robust foundation for reducing production errors with Cloud ERP for small-scale production and ensuring sustainable growth.

Real-Time Data: The Foundation for Error Reduction

In the fast-paced environment of small-scale production, timely information is not just beneficial; it’s absolutely critical for preempting and reducing production errors with Cloud ERP for small-scale production. The ability of Cloud ERP to provide real-time data acts as the vigilant eyes and ears of your entire operation, offering an immediate snapshot of what’s happening on the shop floor, in your inventory, and across your supply chain. This immediate visibility transforms reactive problem-solving into proactive error prevention.

Imagine a scenario where a specific machine starts to operate outside its optimal parameters, or a batch of raw materials arrives with a slight defect. Without real-time data, these issues might go unnoticed until they’ve already contributed to a significant number of faulty products, leading to substantial waste and rework. A Cloud ERP system, however, can integrate with IoT sensors on machinery or track incoming material quality data instantly, flagging anomalies as they occur. This allows production managers to intervene immediately, halting production or adjusting processes before errors propagate.

This immediate access to data also extends to inventory levels. Small manufacturers often struggle with accurate stock counts, leading to either costly overstocking or, worse, critical material shortages that halt production. Cloud ERP continuously updates inventory as materials are consumed in production or received from suppliers. If a particular component is running low and could impact an upcoming production run, the system can automatically trigger alerts or even reorder processes, preventing delays and the associated errors that arise from rushing or improvising due to material constraints.

Furthermore, real-time data empowers better decision-making across the board. Production schedules can be dynamically adjusted based on actual progress, material availability, or sudden changes in demand, minimizing bottlenecks and idle time. Quality control checks can be integrated directly into the workflow, with data immediately recorded and analyzed, allowing for instantaneous identification of any deviations from quality standards. This continuous feedback loop, facilitated by Cloud ERP, is the bedrock upon which efficient, error-free production is built, making it indispensable for reducing production errors with Cloud ERP for small-scale production.

Streamlining Production Workflows and Processes

One of the most potent ways Cloud ERP contributes to reducing production errors with Cloud ERP for small-scale production is by thoroughly streamlining and standardizing production workflows. Many small businesses, due to their organic growth, often end up with ad-hoc processes that are inefficient, prone to human error, and difficult to scale. A Cloud ERP system brings much-needed structure and consistency, transforming chaotic operations into predictable, error-resistant sequences.

Cloud ERP allows businesses to define, document, and enforce standardized operating procedures (SOPs) for every step of the manufacturing process. From raw material intake to final product assembly and packaging, each task can have clearly defined steps, required inputs, and expected outputs. This standardization eliminates guesswork, ensuring that every employee performs tasks consistently, regardless of individual experience or interpretation. When a process is standardized and consistently followed, the variables that lead to errors are significantly reduced.

Moreover, Cloud ERP systems can automate many of the repetitive, manual tasks that are common sources of error. For instance, instead of manually transcribing production orders, updating spreadsheets, or calculating material requirements, the ERP system can handle these automatically based on sales orders and Bill of Materials (BOMs). This automation not only saves time but also drastically minimizes the potential for data entry errors, miscalculations, or forgotten steps, which are often the hidden culprits behind production flaws.

The integration capabilities of Cloud ERP further streamline workflows by ensuring seamless information flow between different departments. When a sales order is placed, it immediately triggers the production planning module, which then checks inventory, schedules production, and alerts procurement if new materials are needed. This end-to-end connectivity eliminates the hand-off errors and communication gaps that frequently plague non-integrated systems, ensuring that production always aligns with demand and available resources. By providing this cohesive, automated, and standardized environment, Cloud ERP becomes an invaluable tool for any small manufacturer serious about reducing production errors with Cloud ERP for small-scale production.

Enhanced Inventory Management for Precision

Accurate and efficient inventory management is a cornerstone of successful manufacturing, and a major factor in reducing production errors with Cloud ERP for small-scale production. For small-scale operations, mismanaged inventory can quickly lead to a cascade of problems, from production halts due to missing components to quality issues arising from using expired or incorrect materials. Cloud ERP offers a sophisticated yet user-friendly solution to bring precision to your stock control, directly impacting error rates.

Traditional inventory tracking methods, often relying on manual counts or basic spreadsheets, are inherently prone to inaccuracies. A single miscount can throw off an entire production schedule, leading to the wrong quantity of products being manufactured, or, worse, the production line grinding to a halt because a critical part is believed to be in stock when it isn’t. Cloud ERP systems provide a centralized, real-time view of all inventory items, tracking every single movement—from receipt of raw materials to their consumption in production and the final dispatch of finished goods. This granular visibility ensures that inventory records are always up-to-date and reliable.

With Cloud ERP, small manufacturers can implement advanced inventory strategies such as lot tracking and serial number tracking. This means you can trace every component back to its supplier and forward to the specific product batch it was used in. If a quality issue arises with a particular batch of raw material, you can quickly identify all affected finished products, minimizing recall scope and preventing further errors from propagating. Conversely, if a defect is found in a finished product, you can pinpoint the exact components and production steps involved, facilitating root cause analysis and preventing recurrence.

Beyond tracking, Cloud ERP empowers proactive inventory optimization. It can analyze historical demand, lead times, and production schedules to suggest optimal reorder points and quantities, preventing both overstocking (which ties up capital) and understocking (which causes delays). It can also manage multiple warehouses or storage locations, ensuring materials are always accessible where and when they’re needed. By bringing this level of precision and control to inventory, Cloud ERP directly addresses a major source of production errors, significantly contributing to reducing production errors with Cloud ERP for small-scale production and fostering overall operational excellence.

Quality Control and Traceability Built-In

For small-scale production, maintaining high quality standards is not just a competitive advantage; it’s a fundamental requirement for building trust and ensuring customer loyalty. Reducing production errors with Cloud ERP for small-scale production goes hand-in-hand with robust quality control and comprehensive traceability capabilities, which are core strengths of modern ERP systems. These features move quality from being a reactive inspection process to a proactive, integrated part of every production step.

A Cloud ERP system allows manufacturers to embed quality checks directly into their production workflows. Instead of waiting until the very end to inspect finished goods, critical quality gates can be established at various stages of production. For example, specific measurements, visual inspections, or functional tests can be mandated at certain points, and the production process cannot proceed to the next step until these quality parameters are met and recorded within the ERP. This immediate feedback loop ensures that defects are caught early, when they are least expensive to fix, preventing further value from being added to an already flawed item.

Furthermore, the traceability features within Cloud ERP are invaluable. In industries where compliance and safety are paramount, such as food processing or medical device manufacturing, being able to trace every component, every process, and every operator involved in a product’s creation is non-negotiable. Cloud ERP provides this end-to-end visibility, linking raw material batches, supplier information, machine parameters, operator actions, and quality inspection results to specific finished products or production lots. This means if a defect is discovered, you can quickly identify its origin and scope, whether it’s a faulty batch of material, a miscalibrated machine, or an operator error.

This level of detailed traceability not only aids in error diagnosis and mitigation but also supports regulatory compliance and product recalls, if necessary, allowing for targeted actions rather than broad, costly recalls. By integrating quality assurance into the daily fabric of operations and providing unparalleled traceability, Cloud ERP acts as a powerful guardian against errors. It ensures that small-scale production is not only efficient but also consistently delivers products that meet the highest quality standards, making it an indispensable tool for reducing production errors with Cloud ERP for small-scale production.

Minimizing Rework and Scrap with Proactive Insights

Rework and scrap are the tangible manifestations of production errors, representing wasted materials, wasted labor, and ultimately, lost profits. For small-scale production, where every unit produced contributes significantly to the bottom line, reducing production errors with Cloud ERP for small-scale production by minimizing rework and scrap is a direct path to improved profitability and sustainability. Cloud ERP provides the data and insights necessary to shift from merely counting losses to actively preventing them.

Traditional manufacturing often views rework and scrap as an unavoidable cost of doing business, or as something to be dealt with after the fact. However, a Cloud ERP system changes this perspective by providing granular data that illuminates the root causes of these inefficiencies. By tracking material consumption, production yields, and defect rates in real-time, the ERP can identify patterns and trends. Is a particular machine consistently producing faulty parts? Is a specific raw material supplier delivering subpar goods? Are errors more common during certain shifts or with particular operators? The system can highlight these critical insights.

For instance, if the ERP’s production monitoring module reports an increase in scrap rates for a specific product line, it can prompt a deeper investigation. By cross-referencing this with data from machine maintenance logs, operator training records, or even environmental conditions recorded within the system, managers can quickly pinpoint the exact cause. Perhaps a machine component needs maintenance, or an operator requires refresher training on a specific procedure. This data-driven approach replaces guesswork with actionable intelligence, allowing for targeted interventions before the problem escalates and significantly impacts output.

Furthermore, by integrating Bill of Materials (BOMs) with production execution, Cloud ERP ensures that the correct quantities and types of materials are always allocated for each production run. Discrepancies here often lead to improper assembly, necessitating rework or resulting in scrap. The system can flag deviations from the BOM, preventing incorrect parts from being used or incorrect quantities from being consumed. This proactive validation, coupled with the ability to analyze historical data for continuous improvement, makes Cloud ERP an indispensable tool for dramatically reducing production errors with Cloud ERP for small-scale production and their costly manifestations in rework and scrap.

Predictive Analytics for Maintenance and Downtime

Unexpected equipment breakdowns are a major source of production errors and costly downtime, particularly in small-scale manufacturing where backup machinery might be limited. Reducing production errors with Cloud ERP for small-scale production extends beyond simply improving human processes; it also encompasses optimizing machine performance through sophisticated maintenance strategies. Cloud ERP systems, especially those with advanced analytics capabilities, are increasingly enabling predictive maintenance, shifting from reactive repairs to proactive prevention.

Historically, maintenance in small operations has often been either reactive (fixing things only when they break) or time-based (scheduled maintenance regardless of actual machine health). Both approaches have their flaws: reactive maintenance leads to sudden, disruptive production stoppages and potential damage to work-in-progress, while time-based maintenance can be wasteful if components are replaced prematurely or insufficient if wear occurs faster than anticipated. Predictive maintenance, powered by Cloud ERP, leverages data to forecast potential failures, allowing for maintenance to be performed precisely when needed.

By integrating with IoT sensors on the shop floor machinery, a Cloud ERP system can collect real-time data on machine performance parameters such as temperature, vibration, pressure, and energy consumption. This continuous stream of data is then analyzed by the ERP’s embedded analytics (or integrated specialized modules) to identify subtle deviations or trends that indicate impending failure. For example, an abnormal increase in machine vibration might signal a bearing nearing its end-of-life, or an unexpected rise in motor temperature could point to an overheating issue.

When such anomalies are detected, the Cloud ERP can automatically generate maintenance work orders, alert maintenance personnel, and even suggest the specific parts needed for repair. This allows maintenance to be scheduled during planned downtime or before a critical production run, preventing unexpected breakdowns and the errors that often accompany rushed repairs or stressed equipment. By ensuring machinery operates within optimal parameters, predictive maintenance significantly contributes to reducing production errors with Cloud ERP for small-scale production, leading to more consistent output quality and fewer costly disruptions.

Optimizing the Supply Chain for Consistent Production

The quality and timely arrival of raw materials and components are foundational to smooth production, and issues in the supply chain can quickly cascade into significant production errors. For small-scale operations aiming at reducing production errors with Cloud ERP for small-scale production, optimizing the supply chain is a critical area where Cloud ERP delivers immense value, transforming a potential source of vulnerability into a pillar of strength.

Cloud ERP provides comprehensive tools for supplier management, allowing small manufacturers to maintain a detailed record of all suppliers, their performance history, lead times, quality ratings, and contractual agreements. This centralized database enables informed decision-making when selecting suppliers and monitoring their ongoing performance. If a supplier consistently delivers materials that fail quality checks, or frequently misses delivery deadlines, the ERP system can flag these issues, prompting you to explore alternative options or negotiate improved terms.

Furthermore, integrating procurement and inventory management modules within Cloud ERP ensures that purchasing decisions are always aligned with production schedules and current inventory levels. The system can automatically generate purchase orders based on minimum stock levels, forecasted demand, and current production plans, minimizing the risk of material shortages that can bring a production line to a halt. Conversely, it prevents over-ordering, which ties up capital and can lead to issues with material obsolescence or storage.

Beyond simple ordering, Cloud ERP also enhances supply chain visibility. It can track orders from placement through shipping and delivery, providing real-time updates on material arrival times. This foresight allows small manufacturers to anticipate and mitigate potential delays, adjusting production schedules proactively rather than reacting to unexpected shortages. By fostering stronger supplier relationships, streamlining procurement processes, and improving material flow, Cloud ERP ensures a consistent input of high-quality materials, which is crucial for reducing production errors with Cloud ERP for small-scale production and maintaining the integrity of the manufacturing process from start to finish.

Selecting the Right Cloud ERP for Your Small-Scale Business

The decision to invest in a Cloud ERP system is significant, and for small-scale production, selecting the right solution is paramount to successfully reducing production errors with Cloud ERP for small-scale production. The market offers a wide array of options, and choosing one that aligns perfectly with your specific operational needs, budget, and growth trajectory requires careful consideration beyond just features.

Firstly, evaluate the ERP’s industry-specific capabilities. While many ERPs are general-purpose, some are designed with manufacturing, or even specific sub-sectors of manufacturing, in mind. Look for features that directly address your unique production processes, such as robust Bill of Materials (BOM) management, production scheduling specific to your type of output (e.g., discrete, process, or mixed-mode), and quality control modules that fit your compliance requirements. A generic ERP might force you to adapt your processes to the software, which can be counterproductive and lead to more errors rather than fewer.

Secondly, consider scalability and flexibility. As a small-scale production business, you’re likely aiming for growth. Your chosen Cloud ERP should be able to grow with you, accommodating increased user numbers, more complex production lines, and additional functionalities without requiring a complete system overhaul. Look for a modular design that allows you to start with essential features and add more advanced capabilities as your business evolves. A flexible system can adapt to changes in your business model or market demands, ensuring long-term value.

Finally, prioritize user-friendliness, vendor support, and total cost of ownership. A powerful ERP is useless if your team finds it too complex to use, leading to poor adoption and continued errors. Look for intuitive interfaces and comprehensive training resources. Investigate the vendor’s reputation for customer support, as you’ll rely on them for ongoing assistance and updates. Understand the full cost—not just the subscription fee, but also potential implementation costs, training expenses, and any third-party integrations required. A well-chosen Cloud ERP should be a strategic investment that pays dividends by efficiently reducing production errors with Cloud ERP for small-scale production, not a drain on your resources.

Smooth Implementation Strategies for Small Manufacturers

Implementing a new Cloud ERP system, even for a small-scale production environment, can seem like a daunting task. However, with a well-planned and executed strategy, it can be a smooth transition that rapidly delivers the benefits of reducing production errors with Cloud ERP for small-scale production. The key is to approach implementation systematically, engaging stakeholders, and focusing on a phased rollout.

A critical first step is thorough planning and defining clear objectives. Before a single line of code is configured, spend time outlining what you want to achieve with the ERP. What specific production errors are you trying to eliminate? What processes do you want to streamline? Clearly defined goals will guide the entire implementation process, from selecting the right modules to configuring them correctly. Involve key personnel from different departments – production, inventory, sales – in this planning phase to ensure their needs are understood and met.

Next, prioritize a phased implementation approach. Instead of trying to roll out every module and feature at once, which can overwhelm a small team, consider a gradual rollout. Start with the most critical modules that address your most pressing pain points, such as inventory management and production scheduling. Once these are stable and users are comfortable, introduce additional functionalities like quality control or advanced analytics. This phased approach reduces disruption, allows your team to adapt incrementally, and provides early wins that build momentum and confidence.

Finally, emphasize comprehensive training and ongoing support. Even the most intuitive Cloud ERP system requires proper training for users to leverage its full potential. Invest in training sessions tailored to different user roles, providing hands-on experience and addressing specific workflow scenarios. Designate internal “champions” who can become power users and offer peer-to-peer support. Post-implementation, ensure there’s a clear channel for users to ask questions and report issues. Continuous feedback and support are vital for maximizing user adoption and ensuring that the ERP truly serves its purpose in reducing production errors with Cloud ERP for small-scale production across your entire operation.

Measuring the ROI: Beyond Just Error Reduction

While reducing production errors with Cloud ERP for small-scale production is a primary objective, the return on investment (ROI) from a Cloud ERP system extends far beyond this single metric. To truly justify the investment and understand its profound impact, small manufacturers should evaluate a broader spectrum of benefits, both tangible and intangible, that collectively contribute to enhanced profitability and operational excellence.

Tangible benefits often include significant cost savings derived from multiple areas. Beyond the reduction in scrap and rework, there are savings from optimized inventory levels—less capital tied up in excess stock, reduced storage costs, and minimized obsolescence. Increased operational efficiency translates to higher throughput with the same or fewer resources, effectively lowering the cost per unit produced. Furthermore, improved demand forecasting means less overproduction or underproduction, aligning output more closely with customer orders and reducing costly rush orders or lost sales. These are direct financial gains that are measurable and contribute significantly to the bottom line.

Intangible benefits, though harder to quantify immediately, are equally crucial. Improved data accuracy and real-time insights lead to better, faster decision-making across all levels of the business, enabling agile responses to market changes or unforeseen challenges. Enhanced customer satisfaction, stemming from higher quality products and more reliable delivery times, strengthens brand loyalty and can lead to increased sales through positive word-of-mouth. Employee morale also tends to improve as frustrating manual tasks are automated, and teams have clearer processes and tools to succeed, reducing stress and increasing productivity.

Ultimately, Cloud ERP positions small-scale production for sustainable growth. By creating a more efficient, agile, and error-resistant operation, it allows businesses to scale without being bottlenecked by manual processes or information silos. It provides a robust foundation for future innovation, whether that’s introducing new product lines, expanding into new markets, or adopting further advanced technologies. Therefore, when assessing the value of Cloud ERP, it’s essential to look beyond just the immediate savings from error reduction and consider the holistic transformation it brings to your small-scale manufacturing business, ensuring a much higher, long-term ROI.

Conclusion: Empowering Precision in Small-Scale Production

The journey of reducing production errors with Cloud ERP for small-scale production is a transformative one, offering a clear pathway for small manufacturers to overcome their unique challenges and thrive in a competitive landscape. We’ve explored how a comprehensive Cloud ERP system fundamentally changes the game, moving operations from reactive firefighting to proactive, data-driven precision. It’s about building a resilient foundation that not only minimizes mistakes but also fosters continuous improvement and sustainable growth.

From providing real-time data that acts as an early warning system to streamlining complex workflows and enhancing inventory accuracy, Cloud ERP systematically targets the root causes of production errors. It brings a level of traceability and quality control that ensures every product meets stringent standards, while also minimizing the costly burden of rework and scrap. By adopting predictive maintenance, it keeps your machinery running optimally, further safeguarding against unexpected disruptions and quality deviations. Moreover, an optimized supply chain ensures a steady flow of high-quality inputs, closing the loop on potential error sources.

The shift to Cloud ERP isn’t merely an upgrade in software; it’s a strategic investment in the future of your small-scale production business. By choosing the right solution, implementing it thoughtfully, and focusing on its broad impact, you empower your team with the tools and insights needed to consistently deliver excellence. The result is a more efficient, more profitable, and ultimately, more successful manufacturing operation, truly mastering the art of reducing production errors with Cloud ERP for small-scale production. The time to embrace this powerful technology and unlock your full potential is now.