The landscape of small manufacturing is a dynamic arena, constantly challenged by fluctuating market demands, rising operational costs, and the relentless pressure to deliver quality products faster. For many, the warehouse, often seen as a mere storage facility, actually holds the key to unlocking significant efficiencies and competitive advantages. However, without a strategic approach, it can quickly become a bottleneck, hindering growth and eroding profits. This is precisely where the power of an Enterprise Resource Planning (ERP) system tailored for small manufacturing becomes indispensable, particularly when focused on optimizing warehouse inventory layouts. It’s not just about stacking boxes; it’s about intelligent design, data-driven decisions, and creating a seamless flow from raw materials to finished goods that can fundamentally transform a small manufacturer’s operations.

Imagine a world where every item in your warehouse is precisely accounted for, where picking routes are minimized, and where raw materials arrive at production lines exactly when needed. This isn’t a futuristic dream; it’s the tangible reality that a well-implemented ERP system can deliver, especially when its capabilities are harnessed to reshape and refine your physical inventory space. For the small manufacturer, whose margins can be tight and resources often stretched, such optimization isn’t a luxury – it’s a strategic imperative for survival and sustained prosperity in a competitive global market.

The Unique Inventory Challenges Faced by Small Manufacturers

Small manufacturing businesses operate under a distinct set of constraints and opportunities that directly impact their inventory management. Unlike their larger counterparts, they often lack the capital for expansive, purpose-built warehouses or advanced automation systems. Their storage spaces might be smaller, multi-purpose, or even inherited, leading to less-than-ideal layouts that evolve organically rather than strategically. This organic growth, while sometimes charming, can quickly devolve into chaos, characterized by misplaced items, slow retrieval times, and an abundance of wasted space.

Furthermore, small manufacturers frequently juggle a diverse product portfolio, often including custom orders or niche products with varying demand patterns. This complexity makes accurate forecasting a Herculean task, contributing to either excessive holding costs from overstocking or crippling production delays due to stockouts. Without a robust system to track inventory movement, analyze sales trends, and predict material needs, the warehouse becomes a reactive environment, constantly scrambling to address immediate crises rather than proactively optimizing for efficiency. These inherent challenges underscore the critical need for an integrated solution that can bring order and intelligence to the heart of their operations.

What is ERP and Why It’s Crucial for Small Manufacturing Operations?

At its core, Enterprise Resource Planning (ERP) is a comprehensive software system designed to integrate and manage all the essential facets of a business. Think of it as the central nervous system of your company, connecting different departments – from finance and human resources to production and supply chain – onto a single, unified platform. For small manufacturers, this integration is not merely a convenience; it’s a strategic necessity that replaces disparate, often manual, systems with a cohesive, data-driven framework. Instead of using separate spreadsheets for inventory, another program for accounting, and yet another for production scheduling, an ERP system consolidates all this vital information.

The true power of an ERP system for small manufacturing lies in its ability to provide a real-time, holistic view of the entire operation. This means that when a sales order comes in, the system can instantly check inventory levels, schedule production, order necessary raw materials, and even track the financial implications, all without human intervention across multiple platforms. This level of interconnectedness eliminates data silos, reduces manual errors, and provides the accurate, up-to-the-minute information necessary for informed decision-making. Without this integrated view, small manufacturers often find themselves making decisions based on incomplete or outdated data, leading to inefficiencies that directly impact profitability and customer satisfaction.

Bridging the Gap: ERP’s Role in Warehouse Inventory Management

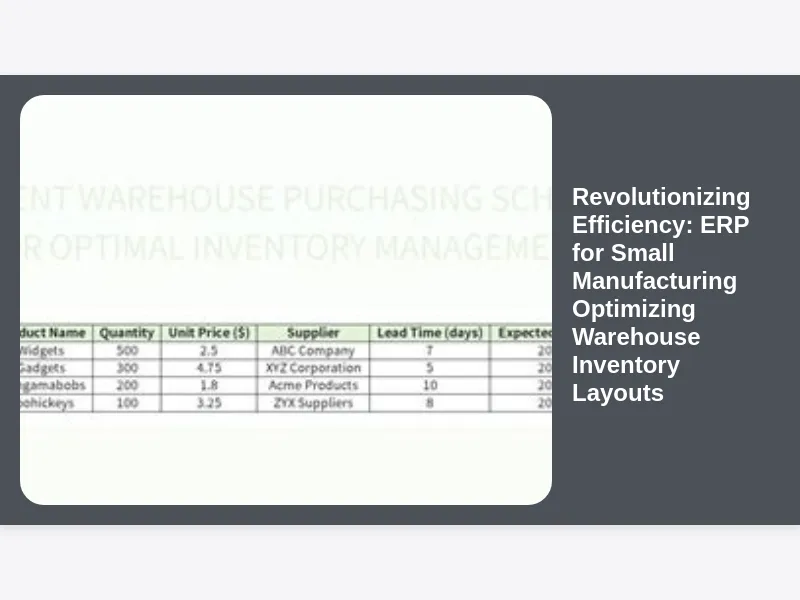

An ERP system serves as the foundational bridge connecting the strategic decisions made in the boardroom to the operational realities on the warehouse floor. It transforms warehouse inventory management from a series of isolated tasks into a highly integrated and optimized process. Before ERP, decisions about where to store items or how to arrange the warehouse might have been based on anecdotal experience or immediate convenience, leading to suboptimal layouts. With ERP, these decisions become data-driven, informed by real-time inventory levels, demand forecasts, production schedules, and even order fulfillment patterns.

The system pulls data from various modules – sales, production, purchasing – to paint a complete picture of inventory needs and movement. For instance, when a production order is initiated, the ERP system knows exactly which raw materials are required, where they are located in the warehouse, and their current quantities. This granular visibility allows for proactive planning, ensuring that materials are staged efficiently and that storage locations are optimized based on factors like frequency of access, size, and weight. By consolidating this information, ERP empowers manufacturers to move beyond reactive inventory management and embrace a truly strategic approach to their warehouse operations, directly influencing layout efficiency.

Understanding Warehouse Inventory Layouts: Principles and Practices

Optimizing warehouse inventory layouts is far more than just finding a place for everything; it’s about designing a space that maximizes efficiency, safety, and accessibility. The fundamental principles revolve around minimizing travel time, streamlining processes, and making the best use of available cubic space. Common layout strategies include fixed location storage, where each item has a permanent home; random storage, where items are placed in the nearest available spot; and zone picking, where the warehouse is divided into sections, and pickers only operate within their assigned zone. Each of these approaches has distinct advantages and disadvantages, and the optimal choice often depends on the specific characteristics of the products, the volume of throughput, and the overall operational goals of the small manufacturer.

Beyond the basic storage methodologies, considerations like the placement of receiving and shipping docks, the flow of material from raw materials to work-in-progress and finished goods, and the location of frequently accessed items (fast-movers) near picking stations are paramount. A poorly designed layout can lead to excessive travel distances for personnel and equipment, increased picking errors, and significant bottlenecks during peak periods. Conversely, a well-thought-out layout, informed by data and strategic planning, can dramatically reduce operational costs, improve throughput, and enhance the overall productivity of the warehouse. The challenge for small manufacturers is often the lack of resources or expertise to perform this level of design, which is where ERP becomes a game-changer.

Data-Driven Layout Decisions: How ERP Informs Your Warehouse Design

The true genius of an ERP system in optimizing warehouse layouts lies in its capacity to transform raw operational data into actionable insights for design and redesign. Gone are the days of guessing where to place inventory or making layout changes based on intuition alone. An ERP system collects vast amounts of data on everything from incoming goods and production schedules to sales orders and outbound shipments. This includes critical metrics like item velocity (how quickly an item moves in and out of the warehouse), demand seasonality, storage requirements (temperature, hazardous materials, fragility), and even the frequency with which items are picked together.

By analyzing this wealth of information, ERP can provide concrete recommendations for optimizing your physical space. For instance, it can identify fast-moving products that should be stored in easily accessible locations near shipping docks, or conversely, slow-moving items that can be placed in less accessible, higher-density storage. It can flag items that are frequently kitted together, suggesting their co-location to minimize travel time for assemblers. Furthermore, ERP helps visualize current space utilization, identifying underutilized areas or bottlenecks that might require a layout adjustment. This data-driven approach moves warehouse design from an art to a science, ensuring that every square foot and every cubic inch is employed to its maximum potential, directly contributing to the efficiency of ERP for small manufacturing.

Optimizing Storage Strategies with ERP Insights

With the analytical prowess of an ERP system, small manufacturers gain the ability to move beyond generic storage methods and implement highly optimized strategies tailored to their specific inventory. For instance, while random storage might seem efficient in its simplicity, ERP can reveal that certain product groupings or families are consistently accessed together. This insight might then lead to the implementation of a more targeted zone picking strategy, or a dedicated area for high-volume items, significantly reducing picker travel time and improving order accuracy. The system can also help in evaluating the feasibility of different storage equipment, from traditional shelving to pallet racking and even automated storage and retrieval systems (AS/RS), by providing data on space utilization and potential throughput improvements.

Moreover, ERP’s real-time inventory tracking allows for dynamic adjustments to storage. If a particular product line experiences an unexpected surge in demand, the system can recommend moving those items to more accessible locations without disrupting the entire warehouse flow. It can also help manage the delicate balance between inventory density and accessibility. For small manufacturers with limited space, this is crucial; ERP can suggest strategies like vertical storage solutions or narrow-aisle racking, backed by data on the space savings and operational impact. This proactive and adaptive approach to storage, empowered by ERP, ensures that the warehouse remains a fluid and responsive environment, always optimized for current and future needs, which is a cornerstone of ERP for small manufacturing: optimizing warehouse inventory layouts.

Streamlining Material Flow and Kitting Processes

One of the most profound impacts of an ERP system on a small manufacturing warehouse is its ability to streamline the flow of materials and optimize kitting processes. In many small operations, material movement can be chaotic, leading to unnecessary handling, delays, and increased labor costs. An ERP system, by integrating production schedules with inventory levels, ensures that raw materials are delivered to the right production line at the precise moment they are needed, adhering to just-in-time (JIT) principles where appropriate. This minimizes the accumulation of work-in-progress (WIP) on the factory floor, reduces clutter, and ensures a smoother, more continuous production flow.

Furthermore, for manufacturers who engage in kitting (assembling various components into a single kit for production or sale), ERP becomes invaluable. It can automatically generate kitting lists, identify all necessary components, pinpoint their exact warehouse locations, and even suggest the most efficient picking path. This not only speeds up the kitting process but also drastically reduces errors, ensuring that production lines receive complete kits, preventing costly stoppages. The system can even track the individual components within a kit, providing full traceability and inventory accuracy, which is essential for quality control and compliance. This integration of material flow and kitting exemplifies how ERP for small manufacturing is about optimizing far more than just static storage.

Inventory Accuracy and Visibility: The Foundation of Good Layout

At the heart of any effective warehouse layout and efficient operation lies impeccable inventory accuracy and real-time visibility. Without knowing exactly what you have and where it is, even the most meticulously planned layout can quickly unravel into disarray. This is where an ERP system truly shines, providing the foundational data integrity that allows for meaningful layout optimization. Traditional manual inventory counts are time-consuming, prone to human error, and often only provide a snapshot of inventory at a specific moment, quickly becoming outdated.

An ERP system, particularly when integrated with barcode scanning, RFID technology, or other automated data capture methods, offers continuous, real-time tracking of every item’s movement. From the moment goods are received, through their various stages in the warehouse, to their eventual shipment or consumption in production, every transaction is recorded and updated instantly. This provides unparalleled visibility into stock levels, specific locations, and historical movement patterns. With this accurate, up-to-the-minute information, manufacturers can trust their data to make informed decisions about layout adjustments, reorder points, and allocation strategies, making the concept of ERP for small manufacturing: optimizing warehouse inventory layouts a practical reality.

Leveraging ERP for Demand Forecasting and Space Planning

Effective demand forecasting is a critical component of intelligent space planning within a warehouse, and an ERP system dramatically enhances a small manufacturer’s capabilities in this area. By analyzing historical sales data, seasonal trends, promotional impacts, and even external market factors, ERP can generate more accurate demand forecasts than manual methods could ever achieve. This predictive capability directly influences how warehouse space is utilized, allowing manufacturers to anticipate future inventory needs and adjust their layouts accordingly.

For example, if the ERP system predicts a surge in demand for a particular product line in the coming months, the warehouse manager can proactively allocate more accessible space for those items, or even reconfigure aisles to accommodate increased picking activity. Conversely, for products projected to decline in demand, their allocated space can be reduced or repurposed. This forward-looking approach, driven by ERP analytics, enables dynamic space planning, preventing both underutilization and overcrowding. It ensures that the warehouse layout remains responsive to market changes, maximizing the efficiency of every square foot and reducing the need for costly, reactive reconfigurations.

Enhancing Order Fulfillment Efficiency with Optimized Layouts

The ultimate goal of an optimized warehouse layout, particularly for a small manufacturer, is to significantly enhance order fulfillment efficiency. Every second saved in picking, packing, and staging directly translates into faster delivery times, reduced labor costs, and improved customer satisfaction. An ERP system, when integrated with a thoughtfully designed layout, orchestrates a symphony of efficiency across the entire fulfillment process. It ensures that when an order is received, the system not only identifies the required items but also calculates the most efficient picking path, minimizing travel time and reducing the chances of errors.

By leveraging the layout insights derived from ERP data, items frequently ordered together can be co-located, and high-velocity items can be placed in prime, easily accessible spots. This design significantly cuts down on the physical effort and time spent by warehouse personnel. Furthermore, ERP can integrate with automated picking technologies, even basic ones like pick-to-light or voice picking systems, further streamlining the process. The result is a fulfillment operation that is not only faster and more accurate but also more adaptable to varying order volumes, a crucial advantage for small manufacturers striving to compete on service and delivery speed.

Scalability and Flexibility: Designing for Growth with ERP

For small manufacturers, growth is the ultimate aspiration, but it often brings with it the challenge of outgrowing existing infrastructure, particularly the warehouse. A primary advantage of implementing ERP for small manufacturing is its inherent ability to support scalability and flexibility in warehouse design. Rather than being stuck with a static layout that quickly becomes inefficient as product lines expand or production volumes increase, an ERP system enables a dynamic and adaptive approach to space management. As your business evolves, the ERP system continuously collects data on new product introductions, changing demand patterns, and shifts in inventory profiles.

This ongoing data analysis allows manufacturers to proactively identify potential future bottlenecks or opportunities for space optimization. For example, if the ERP forecasts significant growth in a particular product category, it might suggest reconfiguring a section of the warehouse to accommodate specialized racking or a new picking zone. Furthermore, the system helps in evaluating the impact of different growth scenarios on the current layout, allowing for strategic decisions about expansion, new equipment acquisition, or even the potential need for additional storage facilities. By providing the tools for continuous assessment and intelligent forecasting, ERP ensures that the warehouse layout can evolve with the business, supporting growth without sacrificing efficiency or incurring prohibitive costs.

The Human Element: Training and Adoption in ERP-Driven Layouts

While technology is a powerful enabler, the success of ERP for small manufacturing, especially in optimizing warehouse inventory layouts, ultimately hinges on the people who interact with the system and the physical space daily. Implementing an ERP-driven layout transformation requires more than just installing software; it demands a significant investment in training and fostering user adoption. Warehouse personnel, from material handlers to pickers and supervisors, need to understand not only how to use the ERP system but also why the changes to the layout are being made and how these changes benefit their daily tasks.

Effective training should go beyond basic system navigation, covering concepts like optimized picking paths, proper scanning procedures, and understanding the rationale behind specific storage locations. Cultivating a culture of continuous improvement, where employees feel empowered to provide feedback on the new layout and system processes, is also crucial. When employees understand the “big picture” – how their role contributes to overall efficiency and how the ERP system supports them – they are more likely to embrace the changes and become advocates for the new processes. This human element, often overlooked in technology implementations, is paramount for unlocking the full potential of an ERP-optimized warehouse.

Overcoming Implementation Challenges for Small Manufacturing ERP

Implementing an ERP system, particularly one focused on optimizing warehouse inventory layouts, is a significant undertaking for any small manufacturing business. It’s not without its challenges, and addressing these proactively is key to a successful deployment. One common hurdle is the initial cost and resource allocation; small businesses often operate with tighter budgets and fewer IT personnel than larger enterprises. Choosing the right ERP solution that is scalable and offers a favorable total cost of ownership (TCO) is paramount. Another challenge is data migration; moving existing inventory data, often residing in disparate spreadsheets or legacy systems, into the new ERP can be complex and time-consuming, requiring meticulous planning and data cleansing.

Resistance to change from employees, as discussed previously, can also be a significant obstacle. This highlights the importance of strong leadership, clear communication, and comprehensive training programs. Furthermore, the implementation process itself can be disruptive to ongoing operations. Small manufacturers must carefully plan the rollout, perhaps adopting a phased approach, to minimize downtime and ensure a smooth transition. Engaging with experienced ERP consultants, choosing a vendor with a proven track record in small manufacturing, and dedicating internal champions to the project can significantly mitigate these challenges, paving the way for a successful transformation of the warehouse and wider operations.

Measuring Success: KPIs for ERP and Warehouse Optimization

To truly understand the impact of ERP for small manufacturing in optimizing warehouse inventory layouts, it’s essential to establish clear Key Performance Indicators (KPIs) and regularly measure their progress. Without defined metrics, it’s impossible to quantify the return on investment (ROI) or identify areas for further improvement. Relevant KPIs for warehouse optimization include pick accuracy rates, order fulfillment cycle time, inventory turnover ratio, inventory accuracy percentage (e.g., from cycle counts), space utilization rate, and cost per pick.

An ERP system simplifies the collection and analysis of these KPIs, providing dashboards and reports that offer real-time insights into performance. For instance, by tracking pick accuracy before and after a layout change informed by ERP, a manufacturer can directly assess the improvement. Similarly, a reduction in the order fulfillment cycle time or an increase in inventory turnover directly demonstrates the efficiency gains. Consistent monitoring of these metrics allows small manufacturers to continuously refine their warehouse operations, ensuring that the ERP system continues to deliver tangible benefits and that the optimized layout remains effective and responsive to evolving business needs.

Future Trends: AI, IoT, and Advanced Analytics in Warehouse Layouts

The journey of ERP for small manufacturing: optimizing warehouse inventory layouts is far from static; it’s an evolving field with exciting future trends promising even greater efficiencies. Artificial Intelligence (AI) and Machine Learning (ML) are set to revolutionize demand forecasting, making it even more precise by identifying subtle patterns and external influences that human analysts might miss. This enhanced predictive power will allow for hyper-optimized layout adjustments, anticipating inventory needs with unprecedented accuracy. The Internet of Things (IoT) will also play a crucial role, with smart sensors deployed throughout the warehouse tracking equipment movement, environmental conditions, and even individual item locations in real-time.

Imagine forklifts that communicate their location and task completion to the ERP, or smart shelves that automatically reorder when stock runs low. Advanced analytics, fueled by this vast stream of data, will enable dynamic layout adjustments, suggesting optimal storage locations based on real-time traffic patterns, energy consumption, and equipment availability. These emerging technologies will move warehouse optimization from a periodic project to a continuous, self-optimizing process, further empowering small manufacturers to compete with larger players by harnessing cutting-edge efficiency. Integrating these capabilities into future ERP iterations will unlock new levels of productivity and responsiveness.

Choosing the Right ERP Solution for Your Small Manufacturing Business

Selecting the appropriate ERP solution is a monumental decision for any small manufacturing business, as it will profoundly impact operational efficiency, financial health, and future growth potential, especially concerning warehouse inventory layout optimization. The first step involves a thorough assessment of your current processes and identifying your most pressing pain points. Are you struggling with inventory accuracy, slow order fulfillment, or inefficient production scheduling? The chosen ERP must directly address these core challenges. It’s crucial to look for solutions specifically designed for manufacturing, as they will include modules for production planning, material requirements planning (MRP), and quality control that generic ERPs might lack.

Scalability is another non-negotiable factor. Your ERP should be able to grow with your business, accommodating increased product lines, higher production volumes, and potentially new warehouse facilities without requiring a complete overhaul. Consider deployment options: cloud-based ERPs offer flexibility, lower upfront costs, and easier maintenance, while on-premise solutions provide more control over data and customization. Finally, don’t underestimate the importance of vendor support and the implementation partner. A good partner will understand your specific industry needs, provide comprehensive training, and offer ongoing support to ensure you maximize the value of your ERP investment in optimizing warehouse inventory layouts.

Case Studies: Real-World Examples of ERP-Driven Warehouse Success

While the theories behind ERP and warehouse optimization are compelling, real-world examples often provide the most convincing evidence of their transformative power. Consider a fictional small parts manufacturer, “Precision Components Inc.,” specializing in custom metal fabrications. Before ERP, their warehouse was a labyrinth of unorganized raw materials and finished goods, leading to frequent mispicks and production delays. After implementing an ERP system with robust inventory management features, they were able to analyze historical data on item velocity and kitting requirements. This led to a complete redesign of their raw material storage, placing frequently used metals closer to the cutting and forming machines, and dedicating specific zones for high-volume components.

Another example is “Artisan Crafts Co.,” a small producer of handcrafted furniture. Their finished goods warehouse often suffered from bottlenecks during peak shipping seasons, with excessive time spent locating specific furniture pieces. Their ERP solution helped them identify that certain furniture collections were always ordered together. By optimizing their finished goods layout to co-locate these collections and streamline picking routes, they reduced their average order fulfillment time by 30% and improved customer satisfaction scores. These hypothetical scenarios illustrate that regardless of the specific manufacturing niche, the principles of ERP for small manufacturing: optimizing warehouse inventory layouts consistently deliver tangible and measurable improvements across various operational metrics.

Beyond the Warehouse: ERP’s Holistic Impact on Small Manufacturing

While this discussion has largely centered on the critical role of ERP for small manufacturing in optimizing warehouse inventory layouts, it’s vital to acknowledge that its impact extends far beyond the physical boundaries of the storage facility. An ERP system acts as a comprehensive business intelligence tool, providing a unified platform that connects all departments. This means that improvements in the warehouse, such as enhanced inventory accuracy and faster material flow, have a ripple effect across the entire organization. Production planning becomes more precise, as raw material availability is guaranteed, leading to fewer delays and reduced downtime.

Sales and customer service benefit from real-time visibility into stock levels, enabling them to provide accurate lead times and reduce instances of backorders. Financial management gains greater control over inventory valuation, cost accounting, and cash flow, as inventory holding costs are minimized. Even human resources can benefit from more accurate workforce planning in the warehouse due to streamlined processes. Ultimately, an ERP system fosters greater collaboration, breaks down departmental silos, and empowers small manufacturers with the integrated data and insights needed to make strategic decisions that drive overall business efficiency, profitability, and sustainable growth, transforming every facet of their operation.

The ROI of ERP for Optimizing Warehouse Layouts

For any small manufacturing business, investing in an ERP system and undertaking warehouse layout optimization is a significant financial decision. Therefore, understanding the potential Return on Investment (ROI) is paramount. The ROI of ERP for optimizing warehouse inventory layouts can be substantial and multifaceted, extending beyond mere cost savings to include enhanced revenue opportunities. Directly, a well-optimized layout reduces labor costs associated with picking, packing, and material handling by minimizing travel time and reducing errors. Improved inventory accuracy leads to fewer stockouts, preventing lost sales, and fewer instances of overstocking, which frees up valuable capital previously tied up in excess inventory.

Furthermore, faster order fulfillment and reduced lead times translate into higher customer satisfaction and repeat business, potentially opening up new market opportunities. The data insights provided by ERP also lead to better purchasing decisions, securing favorable pricing and reducing carrying costs. While quantifying every benefit can be complex, a thorough ROI analysis will typically reveal significant savings and revenue gains within a relatively short period, often offsetting the initial investment. For the small manufacturer looking to gain a competitive edge and build a foundation for scalable growth, the strategic investment in ERP for optimizing warehouse inventory layouts is a decision that consistently pays dividends, offering a tangible pathway to long-term operational excellence and profitability.

Conclusion: The Strategic Imperative of ERP for Small Manufacturing

In the fiercely competitive world of small manufacturing, merely producing quality products is no longer sufficient for sustained success. Operational excellence, underpinned by intelligent systems and optimized processes, has become a strategic imperative. The warehouse, often an overlooked aspect, holds immense potential for unlocking significant efficiencies. As we have explored, an ERP system tailored for small manufacturing offers the most comprehensive and effective pathway to optimizing warehouse inventory layouts. It transforms the warehouse from a chaotic storage space into a highly organized, data-driven hub that seamlessly supports production, accelerates order fulfillment, and ultimately drives profitability.

By integrating critical business functions, providing real-time inventory visibility, and offering the analytical power to make data-driven decisions about space utilization and material flow, ERP empowers small manufacturers to overcome their unique challenges. From reducing operational costs and minimizing errors to enhancing customer satisfaction and fostering scalability, the benefits are profound and far-reaching. Investing in ERP for small manufacturing: optimizing warehouse inventory layouts isn’t just about implementing new software; it’s about embracing a new paradigm of efficiency, agility, and strategic foresight that positions your business for enduring success in a rapidly evolving market. The time to revolutionize your warehouse operations is now.