The landscape of modern manufacturing is evolving at an unprecedented pace, driven by technological advancements and the ever-increasing demand for efficiency, agility, and real-time insights. For small manufacturing businesses, remaining competitive often hinges on their ability to adopt sophisticated tools without disrupting their finely tuned, albeit sometimes traditional, operations. This is where the concept of integrating Cloud ERP into existing small manufacturing workflows becomes not just advantageous, but truly transformative. Many small manufacturers are caught between a desire to modernize and the apprehension of overhauling systems that, while perhaps not perfect, are familiar and functional. This article aims to demystify the process, offering a comprehensive roadmap for making this critical transition smoothly and successfully.

Moving beyond paper-based systems or fragmented spreadsheets can seem daunting, akin to performing open-heart surgery on your business while it’s still running. However, the rewards for successfully embracing a Cloud ERP system are substantial, ranging from improved inventory accuracy and streamlined production planning to enhanced customer satisfaction and a clearer financial picture. We’ll delve deep into the ‘why’ and ‘how,’ addressing common concerns and providing actionable strategies to ensure your journey towards a more integrated, data-driven manufacturing future is a resounding success. By the end of this guide, you’ll have a clearer understanding of how to unlock the full potential of Cloud ERP without crippling your day-to-day operations.

Understanding Cloud ERP: More Than Just Software

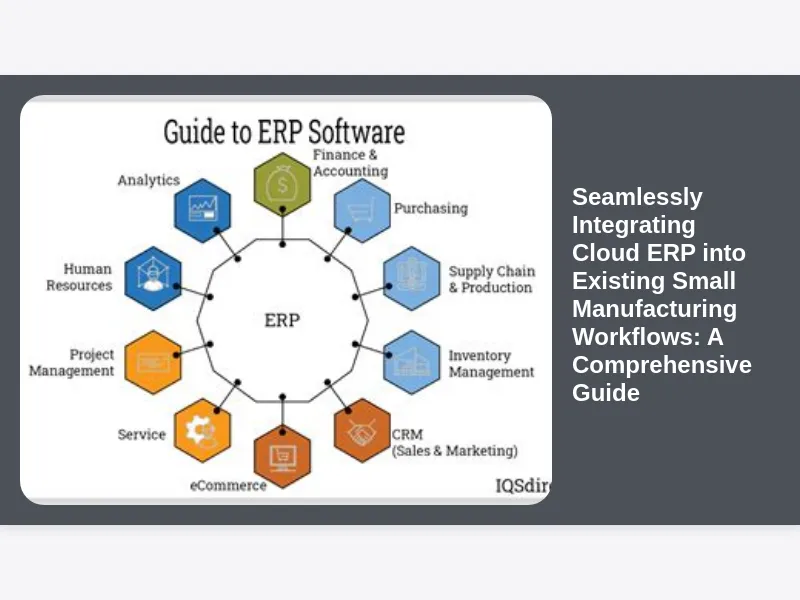

Before we delve into the intricacies of integrating Cloud ERP into existing small manufacturing workflows, it’s crucial to establish a foundational understanding of what Cloud ERP truly entails. At its core, Enterprise Resource Planning (ERP) is a system designed to manage and integrate all facets of an operation, including product planning, development, manufacturing, sales, and marketing. Traditionally, ERP systems were on-premise, requiring significant upfront investment in hardware, software licenses, and dedicated IT infrastructure, which often placed them out of reach for many small manufacturing businesses.

Cloud ERP, however, revolutionizes this model. Instead of being hosted locally, the software and its data are managed by a third-party provider and accessed over the internet, typically through a web browser. This “Software as a Service” (SaaS) model dramatically reduces the initial capital expenditure and ongoing maintenance burden. For small manufacturers, this means access to powerful, enterprise-grade capabilities – from production scheduling and inventory management to accounting and customer relationship management – without the need for an in-house IT department or a massive data center. It’s about subscribing to a service rather than owning a complex system outright, making advanced capabilities far more accessible and scalable.

The Unique Challenges of Small Manufacturing Workflows

Small manufacturing businesses operate within a unique ecosystem, often characterized by agile teams, close-knit operations, and a deep understanding of their specific craft. While these attributes are strengths, they also present particular challenges when considering digital transformation, especially regarding integrating Cloud ERP into existing small manufacturing workflows. Unlike larger enterprises with dedicated IT departments and substantial budgets for system overhauls, small manufacturers typically have limited resources, both in terms of personnel and capital. Their existing workflows, while potentially informal or reliant on tribal knowledge, are deeply ingrained and often highly efficient for their current scale.

One of the primary hurdles is the fear of disruption. The idea of changing established processes, even for the better, can evoke anxiety about production stoppages, order backlogs, or customer dissatisfaction. Many small manufacturers rely on a mix of legacy systems, spreadsheets, and manual record-keeping, which, despite their inefficiencies, are understood and trusted by the workforce. The prospect of migrating critical data, retraining employees, and potentially overhauling every step from raw material procurement to finished goods shipment feels monumental. Furthermore, the sheer variety and specialization of small manufacturing processes mean that a “one size fits all” ERP solution rarely applies, requiring careful consideration to find a system that truly complements their unique operational rhythm rather than forcing a square peg into a round hole.

Key Benefits of Integrating Cloud ERP

The decision to embark on the journey of integrating Cloud ERP into existing small manufacturing workflows is not taken lightly, but the myriad benefits it offers can fundamentally transform a business, propelling it towards greater efficiency, profitability, and future resilience. One of the most immediate and impactful advantages is the unparalleled access to real-time data. Imagine knowing the exact status of every work order, the precise location of every inventory item, and the current financial health of your operations at any given moment, accessible from any device, anywhere. This level of transparency eliminates guesswork, reduces delays, and empowers faster, more informed decision-making across all departments.

Beyond real-time visibility, Cloud ERP systems significantly enhance operational efficiency by automating repetitive tasks and streamlining complex processes. From automated purchase order generation based on inventory levels to intelligent production scheduling that accounts for machine availability and material lead times, the system reduces manual errors and frees up valuable human resources to focus on more strategic activities. This directly translates into cost savings through optimized resource utilization, reduced waste, and improved labor productivity. Furthermore, the scalability of cloud solutions means that as your small manufacturing business grows, your ERP system can easily expand to accommodate increased demand, new product lines, or additional facilities without requiring a complete system overhaul, ensuring your investment continues to yield returns long into the future.

Phase 1: Assessing Your Current State and Future Needs

Before you even begin to research specific vendors or features for integrating Cloud ERP into existing small manufacturing workflows, the most critical first step is a thorough and honest assessment of your current operational state. This involves meticulously documenting your existing workflows, from the moment a customer places an order to the final shipment and everything in between. What software are you currently using, if any? How is data shared (or not shared) between departments? Where are the bottlenecks, the manual processes, the areas prone to errors, and the significant time sinks? Engage employees from all levels – shop floor, purchasing, sales, finance – to gain a holistic perspective on daily operations and pinpoint specific pain points.

This initial assessment is not just about identifying problems; it’s equally about understanding your current strengths and what makes your small manufacturing business unique. Are there specific proprietary processes or highly specialized machinery that need particular consideration? Furthermore, this phase requires a clear articulation of your future needs and strategic objectives. What are your growth aspirations for the next 3-5 years? Do you plan to expand into new markets, launch new product lines, or increase production volume significantly? What regulatory compliance issues might you face? By understanding both where you are and where you want to go, you can develop a comprehensive set of requirements that will guide your ERP selection and ensure the system genuinely supports your long-term vision, rather than simply patching immediate problems. This foundational work is indispensable for a successful ERP implementation.

Defining Your Integration Goals and Objectives

Once you have a clear picture of your current state and have identified key pain points, the next crucial step in integrating Cloud ERP into existing small manufacturing workflows is to meticulously define your specific integration goals and objectives. This goes beyond a vague desire for “better efficiency”; it involves setting concrete, measurable, achievable, relevant, and time-bound (SMART) targets. For example, instead of aiming for “improved inventory management,” a SMART goal might be “reduce inventory discrepancies by 20% within 12 months of ERP Go-Live” or “decrease order fulfillment lead time by 15% within six months.” These precise objectives provide a clear roadmap and allow you to measure the success of your Cloud ERP implementation accurately.

These objectives should directly address the pain points identified during your assessment phase and align with your broader business strategy. Consider what specific business processes you want to optimize: Is it real-time visibility into production schedules? Better quality control tracking? More accurate costing? Enhanced supply chain collaboration? Prioritize these objectives based on their potential impact and feasibility. Involve key stakeholders from various departments in this goal-setting process to ensure buy-in and a shared understanding of what success looks like. Clearly defined goals will not only guide your ERP selection but also serve as benchmarks throughout the integration process, helping you stay focused and ensuring the chosen solution truly delivers the intended value for your small manufacturing enterprise.

Selecting the Right Cloud ERP Solution for Your Business

Choosing the correct Cloud ERP solution is arguably the most critical decision when undertaking the task of integrating Cloud ERP into existing small manufacturing workflows. With a multitude of vendors and specialized systems available, this selection process can feel overwhelming. Begin by revisiting the comprehensive requirements list you developed during your assessment and goal-setting phases. This document should serve as your primary filter. Look for solutions specifically designed for small to medium-sized manufacturing businesses, as these are more likely to offer relevant features without the bloat and complexity of enterprise-level systems. Consider industry-specific solutions if your manufacturing niche has unique compliance or operational demands.

Beyond feature sets, delve into the vendor’s reputation, customer support, and track record. Request demonstrations that are tailored to your specific workflows and pain points, rather than generic presentations. Ask for references from similar-sized manufacturing companies and follow up on them diligently. Evaluate the total cost of ownership (TCO), which includes not just subscription fees but also potential implementation costs, training, and ongoing support. Consider the scalability of the solution – can it grow with your business? What are its integration capabilities with other systems you might use, such as CAD software or e-commerce platforms? Finally, pay close attention to the user interface and overall user-friendliness, as ease of adoption will be paramount for your team. A well-chosen system is a partner in your growth, not just another piece of software.

Data Migration Strategies: Moving from Legacy Systems

One of the most technically challenging and critical aspects of integrating Cloud ERP into existing small manufacturing workflows is the process of data migration. Moving your invaluable operational and historical data from disparate legacy systems, spreadsheets, or even physical records into a new Cloud ERP system requires meticulous planning and execution. A common mistake is underestimating the complexity and time required for this phase. Start by identifying all data sources, categorizing the data (e.g., customer records, supplier information, inventory lists, bill of materials, historical sales, production data), and determining its relevance. Not all old data needs to be migrated; some might be archived for historical purposes, while only current and essential data is brought into the new system.

Data cleansing is an indispensable step before migration. Legacy systems often contain duplicate entries, outdated information, or inconsistent formats. Cleaning and standardizing this data proactively will prevent the new ERP system from inheriting existing inaccuracies, ensuring the integrity and reliability of your new data environment. Develop a clear data mapping plan, showing exactly how each piece of information from your old system will correspond to a field in the new ERP. Consider a phased migration approach, starting with less critical data, or even running the old and new systems in parallel for a short period, if feasible, to validate data accuracy. Partner closely with your chosen ERP vendor and potentially an experienced IT consultant to leverage their expertise in developing and executing a robust data migration strategy, ensuring your foundational data is sound and ready to power your new, integrated operations.

Mapping Current Workflows to New ERP Processes

The success of integrating Cloud ERP into existing small manufacturing workflows hinges not just on the technical implementation, but crucially on how well your established operational processes are adapted to the new system. This step involves a detailed “as-is” to “to-be” workflow mapping exercise. Begin by clearly documenting your current, “as-is” processes for every functional area that the ERP will touch: order entry, production planning, inventory management, purchasing, quality control, shipping, and accounting. Understand the sequence of steps, the roles involved, the information exchanged, and the approvals required.

Once you have a clear picture of your current state, work with your ERP vendor or implementation partner to map these processes to the capabilities of the new Cloud ERP system, defining your “to-be” workflows. This is not about forcing your existing, potentially inefficient, processes onto a new system. Instead, it’s an opportunity for business process re-engineering. Leverage the best practices embedded within the ERP to streamline, automate, and optimize your operations. For instance, if your current inventory tracking is manual, the “to-be” process will involve real-time updates through barcode scanning directly into the ERP. Identify where the ERP can eliminate redundant steps, improve data flow, and provide greater transparency. This mapping exercise is critical for identifying configuration needs, customizing the system where necessary (though minimizing customization is often wise), and preparing your team for how their daily tasks will change.

Change Management: Preparing Your Team for the Transition

Even the most technologically advanced and perfectly configured Cloud ERP system will fail if your team isn’t prepared to embrace it. Therefore, change management is an indispensable component when integrating Cloud ERP into existing small manufacturing workflows. This isn’t just about training; it’s about proactively addressing the human element of organizational change, mitigating resistance, and fostering a culture of adoption. Begin by communicating openly and frequently about the upcoming change, explaining why the ERP is being implemented and how it will benefit individuals and the company as a whole. Focus on the advantages for employees – reduced manual work, clearer data, better tools – rather than just management benefits.

Identify key change agents or “champions” within each department. These individuals, who are typically respected by their peers and open to new technologies, can help advocate for the ERP, answer questions, and provide peer support during the transition. Develop a comprehensive training program that is tailored to different user groups and their specific roles within the ERP. Hands-on training, conducted in small groups, with realistic scenarios, is far more effective than generic demonstrations. Provide clear documentation, cheat sheets, and ongoing support channels (e.g., a dedicated help desk, regular check-in meetings). Acknowledge that adaptation takes time, and be prepared to address concerns, provide reassurance, and celebrate small victories along the way. Successful change management transforms potential resistance into enthusiastic adoption, ensuring your investment in Cloud ERP truly pays off.

The Integration Process: Step-by-Step Implementation

With careful planning, data migration, and comprehensive change management strategies in place, the actual technical implementation phase of integrating Cloud ERP into existing small manufacturing workflows can proceed more smoothly. While the specifics will vary based on your chosen vendor and solution, a typical step-by-step process often follows a logical progression. The first step involves system configuration. This is where the ERP is tailored to your specific business rules, workflows, and reporting requirements, based on the mapping exercise you completed earlier. This includes setting up user roles and permissions, defining product structures (BOMs), configuring inventory locations, and establishing accounting parameters.

Following configuration, the cleansed and mapped data is loaded into the new system. This can be a multi-stage process, often starting with master data (customers, suppliers, products) and then moving to transactional data (open orders, work orders, current inventory levels). Comprehensive testing then becomes paramount. This isn’t just about the ERP functioning; it’s about validating that your specific “to-be” workflows are accurately executed within the system. User acceptance testing (UAT) involves key end-users performing their daily tasks in the new system, identifying any issues or discrepancies. Finally, after successful testing and sign-off, the system goes live. This “Go-Live” can be a hard cutover (switching completely to the new system) or a phased approach, where modules are rolled out gradually, allowing for easier adaptation and problem resolution. Regardless of the chosen method, vigilant monitoring and immediate support are crucial in the initial days and weeks post-launch.

Testing and Validation: Ensuring Seamless Operation

A successful integrating Cloud ERP into existing small manufacturing workflows does not conclude with the system being configured and data migrated; exhaustive testing and validation are non-negotiable steps to ensure seamless operation. This phase is about meticulously verifying that the ERP system performs as expected, supports your defined workflows, and accurately processes your business-critical information. Beyond simple functionality checks, comprehensive testing includes several layers. Unit testing confirms that individual components or modules of the ERP (e.g., creating a purchase order, issuing materials to a work order) work correctly in isolation.

System integration testing then verifies that different modules communicate and interact flawlessly with each other, for instance, ensuring that a completed production order correctly updates inventory levels and triggers a financial entry. User Acceptance Testing (UAT) is perhaps the most crucial for small manufacturing businesses, as it involves your actual end-users performing their day-to-day tasks in the new system using real-world scenarios. This helps identify any usability issues, training gaps, or process flows that might not have been fully anticipated. Additionally, performance testing ensures the system can handle your expected transaction volumes and concurrent users without slowdowns. This rigorous validation process helps catch errors before they impact live operations, significantly reduces post-launch disruptions, and builds user confidence in the new system.

Post-Implementation Support and Continuous Improvement

The “Go-Live” of your Cloud ERP system marks a significant milestone, but it is by no means the end of the journey when integrating Cloud ERP into existing small manufacturing workflows. The period immediately following implementation is critical for consolidating gains, addressing emergent issues, and embedding the new system deeply into your organizational DNA. Establish clear channels for post-implementation support, whether it’s a dedicated internal team, a help desk from your ERP vendor, or a combination of both. Users will inevitably have questions, encounter unexpected scenarios, or need refresher training. Prompt and effective support during this stabilization period is essential to prevent frustration and maintain user adoption.

Beyond immediate troubleshooting, the focus should shift towards continuous improvement. An ERP system is not a static solution; it’s a dynamic tool that should evolve with your business. Regularly review system performance, gather user feedback, and identify areas where processes can be further optimized or where additional features of the ERP can be leveraged. Many Cloud ERP providers release regular updates with new functionalities, and it’s important to evaluate how these can further benefit your small manufacturing operations. Schedule periodic business process reviews to ensure that your workflows remain aligned with the system’s capabilities and your strategic objectives. This commitment to ongoing refinement ensures that your Cloud ERP investment continues to deliver maximum value and adaptability as your business grows and market conditions change.

Measuring ROI and Success Metrics

A fundamental part of successfully integrating Cloud ERP into existing small manufacturing workflows is the ability to quantify its impact. Without measuring the Return on Investment (ROI) and key success metrics, it’s difficult to fully appreciate the value delivered or justify the resources expended. Begin by revisiting the SMART goals and objectives you defined at the outset of the project. These should form the backbone of your measurement framework. For instance, if a goal was to “reduce inventory discrepancies by 20%,” you can now track actual inventory accuracy before and after ERP implementation using real-time data from the new system.

Key performance indicators (KPIs) to monitor include, but are not limited to, lead times for order fulfillment, on-time delivery rates, production efficiency (e.g., units per hour, machine utilization), inventory turnover rates, accuracy of financial reporting, customer satisfaction scores, and employee productivity. It’s also important to track less tangible benefits, such as improved decision-making capabilities due to better data, enhanced collaboration across departments, and the reduction of manual errors. Compare these post-implementation metrics against your baseline data collected before the ERP project began. A robust ROI analysis will not only demonstrate the financial benefits (cost savings, increased revenue) but also highlight the operational improvements and strategic advantages gained, providing a clear narrative of your Cloud ERP success story.

Common Pitfalls to Avoid During Integration

While the benefits of integrating Cloud ERP into existing small manufacturing workflows are clear, the path to success is not without potential pitfalls. Awareness of these common challenges can help small manufacturers navigate the implementation process more effectively. One frequent mistake is underestimating the time and resources required. Cloud ERP may remove some IT infrastructure burdens, but it still demands significant internal effort in terms of planning, data preparation, training, and ongoing management. Skimping on these aspects often leads to project delays, cost overruns, and user dissatisfaction.

Another critical pitfall is inadequate data cleansing and migration. Importing dirty, incomplete, or inconsistent data into a new ERP system will only perpetuate existing problems and erode trust in the new system. “Garbage in, garbage out” perfectly applies here. Similarly, insufficient training and poor change management can cripple adoption. If employees don’t understand how to use the system or don’t see its value, they will resist it, resort to old methods, or simply use it incorrectly. Finally, over-customization of the ERP system can be a trap. While some tailoring might be necessary, excessive customization can increase implementation costs, complicate upgrades, and reduce the ability to leverage future innovations from the vendor. Sticking as close to the standard functionality as possible, and adapting your processes to best practices embedded in the ERP, often yields a smoother and more sustainable long-term solution.

Security Considerations for Cloud ERP in Manufacturing

For small manufacturing businesses, the decision to embark on integrating Cloud ERP into existing small manufacturing workflows inevitably raises important questions about data security. Moving critical operational data, intellectual property, financial information, and customer details to the cloud requires a robust understanding of the inherent risks and the measures taken to mitigate them. While cloud providers often boast superior security infrastructure compared to what most small businesses can afford on-premise, vigilance is still paramount. It’s essential to thoroughly vet your chosen Cloud ERP vendor’s security protocols.

Inquire about their data encryption practices, both in transit and at rest. Understand their physical security measures for data centers, their backup and disaster recovery plans, and their compliance with relevant industry standards and certifications (e.g., ISO 27001, SOC 2). Ask about their access control mechanisms, including multi-factor authentication and granular user permissions, which ensure that only authorized personnel can access sensitive information. Beyond the vendor’s responsibilities, your own internal security practices are equally vital. Implement strong password policies, regular employee security training, and ensure your network connections to the Cloud ERP are secure. While the cloud offers immense benefits, a proactive and collaborative approach to security, both from the vendor and your internal team, is crucial for protecting your valuable manufacturing data.

Future-Proofing Your Manufacturing Operations with Cloud ERP

One of the most compelling arguments for integrating Cloud ERP into existing small manufacturing workflows is its inherent ability to future-proof your operations. In an era of rapid technological change and evolving market demands, static systems quickly become obsolete, hindering growth and competitiveness. Cloud ERP, by its very nature, is designed for adaptability and scalability. As your small manufacturing business grows – perhaps by adding new product lines, expanding into new geographies, or increasing production volume – your Cloud ERP system can seamlessly scale to accommodate these changes without requiring a complete overhaul. This elastic capacity means you’re investing in a solution that evolves with you, rather than becoming a bottleneck to your aspirations.

Furthermore, Cloud ERP platforms are typically at the forefront of technological innovation. Vendors regularly release updates, introducing new features, incorporating emerging technologies like AI, machine learning, and IoT integration, and enhancing security measures. This means your system is continuously improving and gaining new capabilities without you needing to invest in separate upgrades or patches. By embracing a Cloud ERP, you are essentially subscribing to a future-ready platform that keeps your small manufacturing business agile, responsive, and equipped with the latest tools to navigate an increasingly complex global marketplace. This strategic foresight ensures that your initial investment continues to yield dividends, propelling your operations forward for years to come.

Conclusion: Embracing the Future of Small Manufacturing

The journey of integrating Cloud ERP into existing small manufacturing workflows is undoubtedly a significant undertaking, demanding careful planning, dedicated resources, and a commitment to change. However, as we’ve explored throughout this guide, the long-term benefits far outweigh the initial challenges. For small manufacturers striving for greater efficiency, real-time visibility, improved decision-making, and scalable growth, Cloud ERP represents a powerful catalyst for digital transformation. It’s about moving beyond the limitations of legacy systems and fragmented data to embrace a unified, intelligent platform that can drive operational excellence and foster sustainable competitive advantage.

By methodically assessing your needs, setting clear goals, carefully selecting the right solution, diligently migrating data, preparing your team, and committing to continuous improvement, your small manufacturing business can successfully navigate this transition. The future of manufacturing is increasingly data-driven, agile, and interconnected. By integrating Cloud ERP into existing small manufacturing workflows, you’re not just implementing new software; you’re investing in a more resilient, responsive, and profitable future for your business. It’s time to unlock your full potential and step confidently into the next era of manufacturing.