Small manufacturing operations are the backbone of many economies, driving innovation and producing essential goods. Yet, in our increasingly digital world, these very businesses face an invisible, persistent threat: data insecurity. From proprietary designs and customer lists to financial records and production schedules, the sheer volume of sensitive information handled by a small manufacturer is staggering. Without robust protection, this data is vulnerable to cyberattacks, accidental breaches, and system failures, any of which could spell disaster. This isn’t just about losing a few files; it’s about reputational damage, financial penalties, operational shutdowns, and potentially the very survival of your business.

Many small manufacturers operate under the misconception that they are too small to be targets, or that sophisticated data security is an expense reserved for larger corporations. This couldn’t be further from the truth. Cybercriminals often specifically target smaller entities, knowing they frequently have weaker defenses. The good news is that an enterprise resource planning (ERP) system, traditionally seen as a tool for efficiency and growth, offers a powerful, integrated solution for securing your data with ERP for small manufacturing operations. It’s not just about managing resources; it’s about safeguarding your most valuable digital assets.

The Unique Data Security Challenges Faced by Small Manufacturers

Small manufacturing businesses, despite their critical role in the economy, often contend with a specific set of vulnerabilities that larger enterprises might mitigate with dedicated IT security teams and extensive budgets. Understanding these unique challenges is the first step toward effective defense. Unlike their larger counterparts, small manufacturers frequently operate with leaner IT departments, sometimes even relying on a single individual or outsourced support, meaning that proactive security measures can often be overlooked or deprioritized in favor of immediate operational demands.

One significant challenge is the reliance on legacy systems and fragmented data storage. Many small manufacturing operations have grown organically, accumulating a patchwork of disparate software applications, spreadsheets, and manual processes over the years. This creates data silos spread across various departments and devices, making consistent security policies incredibly difficult to enforce. Each silo represents a potential entry point for attackers, and the lack of a centralized, unified data management system leaves gaping holes in the overall security posture. This fragmentation also makes it nearly impossible to get a clear, real-time overview of all data, let alone monitor its security status effectively.

Furthermore, small manufacturers are often deeply integrated into larger supply chains, making them a tempting target for sophisticated attackers looking for an entry point into bigger organizations. A breach in a small supplier can serve as a conduit for a more significant attack on a prime contractor, a tactic known as a supply chain attack. This means that the security of a small manufacturing operation isn’t just crucial for its own survival, but for the integrity of an entire network of businesses. Coupled with the common challenge of limited employee awareness regarding cybersecurity best practices – things like strong password policies, phishing recognition, and safe browsing habits – the risk landscape becomes exceptionally complex. Securing your data with ERP for small manufacturing operations directly addresses many of these inherent weaknesses by centralizing, standardizing, and protecting information in a systematic manner.

What is ERP and Why Small Manufacturers Need It Beyond Efficiency

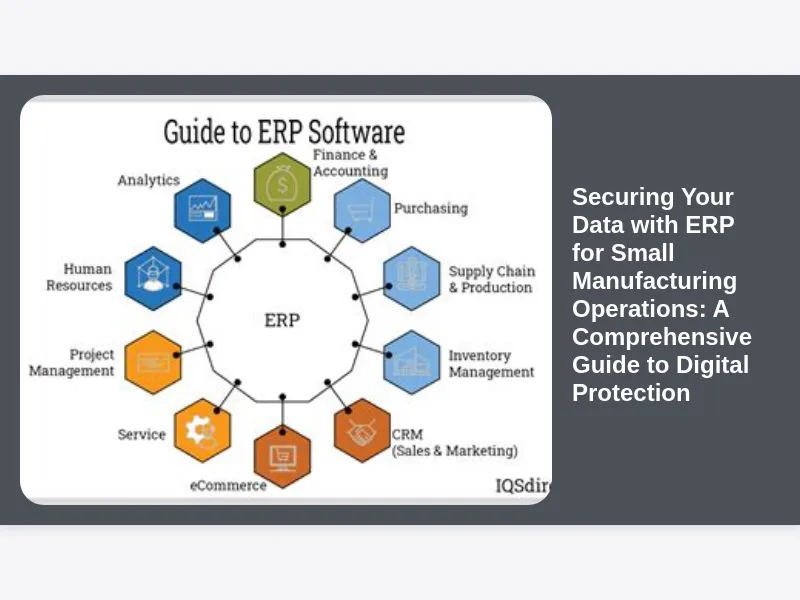

Enterprise Resource Planning (ERP) systems are comprehensive software platforms designed to integrate and manage all the core business processes of an organization into a single, unified system. Think of it as the central nervous system of your manufacturing operation, connecting various functions such as production planning, inventory management, supply chain, purchasing, finance, human resources, and customer relationship management. Traditionally, small manufacturers have adopted ERP primarily for its efficiency gains: streamlining workflows, reducing manual errors, optimizing inventory levels, and improving overall operational visibility. These benefits are undoubtedly transformative, helping businesses do more with less, increase productivity, and make better, data-driven decisions.

However, the value proposition of ERP for small manufacturers extends far beyond mere operational efficiency; it is a foundational element for business resilience and, critically, data security. In an era where data is often considered the new oil, protecting that asset becomes paramount. Without an integrated system, data often resides in disparate spreadsheets, legacy databases, and individual departmental applications, creating a fragmented landscape that is inherently difficult to secure. This lack of centralization doesn’t just hinder efficiency; it creates numerous vulnerabilities, making it challenging to implement consistent security protocols, monitor access, or even track changes effectively.

An ERP system, by its very nature, brings all this critical data under one roof. This centralization is not just about convenience; it’s about establishing a single source of truth for all business information. This unified approach vastly simplifies the task of securing your data with ERP for small manufacturing operations. Instead of having to secure multiple, isolated systems, IT efforts can be concentrated on protecting a single, robust platform. This allows for a more comprehensive and cohesive security strategy, ensuring that all data, from raw material procurement to finished product delivery, is subject to the same rigorous protective measures. It moves data from being a scattered liability to a managed, protected asset.

ERP as a Centralized Data Hub: The Foundation of Security

At the heart of an ERP system’s security capabilities lies its function as a centralized data hub. Imagine your manufacturing operation’s data as a vast collection of valuable documents. Without an ERP, these documents might be scattered across various filing cabinets in different departments, some locked, some not, some potentially misplaced or even duplicated. This chaotic scenario makes it nearly impossible to know exactly what you have, where it is, or who has accessed it. A breach in one area might go unnoticed, and a lost document could have significant repercussions without anyone being fully aware.

An ERP system fundamentally changes this by consolidating all critical business information into a single, unified database. This means that financial records, production schedules, customer orders, supplier contracts, proprietary designs, employee information, and inventory levels no longer reside in isolated silos. Instead, they are all stored within a secure, integrated environment. This consolidation is perhaps the most significant security advantage an ERP offers to small manufacturing operations. It eliminates the need to secure multiple disparate systems, each with its own vulnerabilities and management complexities.

This centralized approach creates a single point of entry and exit for data, which paradoxically, makes it easier to secure. Rather than chasing fragmented data across numerous platforms, security efforts can be focused and intensified on this one critical hub. It allows for consistent application of security policies, simplifies monitoring, and ensures that all information adheres to the same standards of protection. For small manufacturers, who often lack extensive IT resources, this simplification is invaluable, allowing them to leverage the power of enterprise-grade security without the overwhelming complexity. Effectively, securing your data with ERP for small manufacturing operations begins with this fundamental shift from scattered information to a well-organized, centrally controlled digital repository.

Access Control and User Permissions: Granular Security with ERP

Once your data is centralized within an ERP system, the next critical layer of security comes from its robust access control and user permission functionalities. Imagine your manufacturing plant as a secure facility; not everyone has access to every area. The production manager might have keys to the shop floor, but not to the finance office. Similarly, the warehouse supervisor needs access to inventory records but not necessarily to customer payment details. ERP systems apply this same principle digitally, allowing you to define precisely who can access, view, modify, or delete specific types of data.

This granular control is a game-changer for data security in small manufacturing operations. Instead of a blanket “all or nothing” approach, ERP enables you to tailor access rights down to specific modules, functions, or even individual data fields. For example, a shop floor employee might only have permissions to view production orders relevant to their tasks, while the finance team can access financial ledgers but not engineering designs. A sales representative can update customer contact information but cannot alter inventory levels or approve purchase orders. This minimizes the risk of unauthorized access and ensures that employees only interact with the information necessary for their specific roles.

Implementing strong access controls through an ERP system significantly reduces the potential for both accidental data breaches and malicious insider threats. Accidental errors, like deleting critical records, are less likely when users only have permissions to the data they routinely handle. Furthermore, if an employee’s credentials are compromised, the damage is contained to the specific areas they had access to, rather than exposing the entire database. For small manufacturers, this level of control offers peace of mind, knowing that sensitive information is protected by predefined boundaries. Regularly reviewing and updating these user permissions is also a streamlined process within an ERP, ensuring that access rights remain appropriate as roles change or employees leave, further strengthening the effectiveness of securing your data with ERP for small manufacturing operations.

Data Encryption in ERP Systems: Protecting Data at Rest and in Transit

Encryption is a fundamental pillar of modern data security, acting as a digital lockbox for your sensitive information. When you hear about securing your data with ERP for small manufacturing operations, encryption is one of the technical safeguards that makes this possible, both when your data is stored and when it’s moving between systems. Essentially, encryption transforms readable data into a coded, unreadable format that can only be deciphered with a specific key. Without this key, the encrypted data appears as gibberish, rendering it useless to unauthorized individuals who might gain access.

Modern ERP systems employ robust encryption protocols to protect data in two crucial states: “at rest” and “in transit.” Data “at rest” refers to information stored on servers, databases, or cloud storage. This includes all your archived financial records, product designs, customer databases, and historical production data within the ERP system. Encryption at rest ensures that even if an attacker manages to bypass other security layers and gain access to your database files, they will find only scrambled, unusable information. This is particularly vital for small manufacturing operations that store a wealth of proprietary and confidential data that, if exposed, could lead to significant competitive disadvantage or regulatory penalties.

Data “in transit” refers to information as it travels across networks, such as when an employee accesses the ERP from a remote location, when data is exchanged with a supplier via an integrated portal, or when information is backed up to a cloud service. ERP systems secure this communication using protocols like SSL/TLS (Secure Sockets Layer/Transport Layer Security), which encrypt the data packets as they move across the internet or internal networks. This prevents eavesdropping and interception by cybercriminals who might try to capture data during transmission. For small manufacturers increasingly relying on remote work and interconnected supply chains, ensuring that data is encrypted both when stored and when moving is absolutely non-negotiable for truly securing your data with ERP for small manufacturing operations.

Audit Trails and Activity Logging: Accountability and Incident Response

One of the most powerful, yet often underestimated, security features of an ERP system is its comprehensive audit trail and activity logging capabilities. Think of an audit trail as a meticulous, digital logbook that records every significant action performed within the system. This isn’t just a general overview; it’s a detailed, timestamped record of who did what, when, and from where. This level of transparency is invaluable for establishing accountability, detecting suspicious activities, and providing crucial evidence in the event of a security incident or data breach.

Every user login, every data modification, every new entry, and every deletion within the ERP is typically logged. If an employee accesses a sensitive file, changes a production order, or even attempts to log in with incorrect credentials, the system records it. This creates a complete historical record of all data interactions. For small manufacturing operations, where oversight might be limited, these audit trails act as an ever-present digital watchman, significantly deterring insider misuse and making it difficult for unauthorized actions to go unnoticed. It fosters a culture of accountability, as employees know their actions are being recorded.

Beyond deterrence, robust activity logging is absolutely critical for effective incident response. In the unfortunate event of a data breach or suspicious activity, the audit trail provides investigators with a precise timeline and details of what transpired. It helps answer fundamental questions: Who accessed the data? When did the breach occur? What specific information was compromised? This forensic evidence is essential for understanding the scope of a breach, identifying vulnerabilities, and complying with reporting requirements. Without an ERP’s integrated logging, piecing together such information from disparate systems would be a monumental and often impossible task. Therefore, the ability to maintain detailed audit trails is a cornerstone of securing your data with ERP for small manufacturing operations, offering both proactive protection and reactive analytical capabilities.

Disaster Recovery and Business Continuity: ERP’s Role in Resilience

Data security isn’t just about preventing malicious attacks; it’s also about preparing for the unexpected, from hardware failures and natural disasters to human error. For small manufacturing operations, an unplanned outage or data loss event can be catastrophic, leading to production stoppages, missed deadlines, lost revenue, and irreparable damage to customer trust. This is where an ERP system, particularly one with robust disaster recovery (DR) and business continuity (BC) features, becomes an indispensable tool for organizational resilience. It moves beyond merely protecting data to ensuring the entire business can rapidly recover and resume operations.

Modern ERP solutions typically include or integrate with sophisticated backup and recovery mechanisms. This means that your critical manufacturing data – production plans, inventory records, financial ledgers, customer information – is regularly backed up, often to secure off-site locations or cloud storage. These backups are not just simple copies; they are part of a structured recovery plan designed to restore your system and data to a functional state as quickly as possible following a disruption. For cloud-based ERPs, the provider usually manages these complex DR strategies, offering small manufacturers enterprise-grade protection without the burden of maintaining their own extensive IT infrastructure.

A well-implemented ERP system with a defined DR plan ensures that even if your primary servers fail, your facility experiences a power outage, or a major cyberattack renders your active system unusable, your business can rebound. It provides the means to restore operations from a recent backup, minimizing downtime and data loss. This comprehensive approach to data protection and recovery is vital for securing your data with ERP for small manufacturing operations, transforming potential existential threats into manageable disruptions. It underscores that true data security encompasses not just prevention, but also the strategic capacity to recover and continue operating, no matter what challenges arise.

Compliance and Regulatory Requirements: How ERP Simplifies Adherence

The regulatory landscape for businesses, including small manufacturing operations, is becoming increasingly complex. From data privacy laws like GDPR and CCPA to industry-specific standards and cybersecurity frameworks like NIST, compliance is no longer optional; it’s a legal and ethical imperative. Non-compliance can result in hefty fines, reputational damage, and even legal action, posing a significant threat to the viability of a small business. Many small manufacturers find navigating these requirements daunting, often lacking the in-house expertise or resources to ensure full adherence across their disparate systems.

This is where an ERP system offers a powerful advantage. By centralizing all critical data and processes, an ERP inherently simplifies the task of achieving and maintaining compliance. Instead of trying to implement and monitor compliance policies across multiple, disconnected systems, you can apply them uniformly within a single, integrated platform. The audit trails and reporting capabilities of an ERP, as discussed earlier, are particularly valuable here, providing undeniable evidence of data handling practices, access controls, and security measures. This documentation is often a cornerstone of regulatory audits, making the process far less stressful and more straightforward.

Furthermore, many modern ERP solutions are designed with built-in features that specifically support compliance efforts. This can include functionalities for managing data retention policies, tracking consent for customer data, facilitating data subject access requests, and ensuring data anonymization where required. Some ERPs may even offer modules tailored to specific industry regulations, helping manufacturers meet sector-specific standards with greater ease. By streamlining these complex requirements and providing a verifiable record of data governance, securing your data with ERP for small manufacturing operations becomes a key enabler for regulatory adherence, transforming a potential burden into a manageable aspect of doing business responsibly.

Supply Chain Security: Extending Data Protection Beyond Your Walls with ERP

In today’s interconnected world, small manufacturing operations are rarely isolated entities. They are integral links in complex supply chains, collaborating with suppliers, distributors, logistics partners, and customers. While this network offers immense advantages, it also introduces significant security risks. A vulnerability in one part of the supply chain can cascade, exposing sensitive data or disrupting operations for everyone involved. Traditional security approaches often focus solely on internal defenses, but true resilience for small manufacturers requires extending data protection beyond their immediate digital walls.

ERP systems play a crucial role in enhancing supply chain security by providing a centralized platform for managing all supplier and customer interactions. When you share purchase orders, production schedules, specifications, or shipment details with external partners, your ERP can facilitate this exchange securely. Many modern ERPs offer integrated portals or secure APIs (Application Programming Interfaces) that allow for controlled, encrypted communication with trusted partners. This means you’re not relying on insecure email attachments or fragmented manual processes for critical data exchanges, significantly reducing the risk of interception or unauthorized access.

Moreover, an ERP’s ability to provide a single, accurate view of your entire supply chain helps you identify and manage risks proactively. By integrating supplier performance data, compliance certifications, and security attestations directly into your ERP, you can make more informed decisions about who you partner with. If a supplier experiences a breach, your ERP’s real-time visibility and communication tools can help you quickly assess the impact, quarantine affected data, and pivot to alternative solutions. Ultimately, securing your data with ERP for small manufacturing operations extends to fostering a more secure and resilient supply chain, protecting not only your own business but also contributing to the overall integrity of the broader manufacturing ecosystem.

Training and Human Factors: Strengthening Your Security Posture with ERP Data

Even the most technologically advanced ERP system is only as secure as the people who use it. Human error remains one of the leading causes of data breaches, whether it’s falling victim to a phishing scam, using weak passwords, or accidentally misconfiguring settings. For small manufacturing operations with limited dedicated IT security personnel, training employees to be the first line of defense is absolutely critical. An ERP system, while providing robust technical safeguards, also plays a crucial role in simplifying and standardizing processes, thereby reducing the opportunities for human error and enhancing overall security awareness.

Firstly, by centralizing data and standardizing workflows, an ERP system reduces complexity and confusion, which are often breeding grounds for security mistakes. When employees follow clear, consistent procedures within the ERP, they are less likely to make ad-hoc decisions that could create vulnerabilities. The system itself can enforce certain security policies, such as requiring strong passwords, multi-factor authentication, or automatically logging out inactive users, reducing the burden on individual employees to remember every security best practice.

Secondly, an ERP system can be a powerful tool for ongoing security education. By monitoring audit trails and identifying common user mistakes or areas of non-compliance, IT or management can pinpoint where additional training is needed. For example, if logs show frequent failed login attempts from a specific department, it might indicate a need for refresher training on password management or recognition of social engineering tactics. Furthermore, by making security protocols an integral part of daily operations within the ERP, rather than a separate, abstract concept, employees are constantly reminded of their role in protecting sensitive information. Empowering your team with knowledge and making security an embedded part of their digital workflow through ERP is essential for truly securing your data with ERP for small manufacturing operations.

Integrating Cybersecurity Tools with Your ERP: A Layered Security Approach

While an ERP system provides significant built-in security features, it’s important to view it as a foundational layer within a broader, layered cybersecurity strategy. No single solution can offer complete protection against the ever-evolving threat landscape. For small manufacturing operations, integrating specialized cybersecurity tools with their ERP is crucial for creating a robust, multi-faceted defense, providing depth that standalone systems often lack. This layered approach ensures that even if one defense mechanism is breached, others are in place to detect, prevent, or mitigate the attack.

One common integration involves connecting the ERP with endpoint detection and response (EDR) or antivirus software. While the ERP secures its own data, EDR protects the devices (laptops, workstations, servers) that access the ERP, guarding against malware, ransomware, and other threats that could compromise user credentials or directly attack the system from the client side. Similarly, integrating with network firewalls and intrusion detection/prevention systems (IDPS) adds another layer, monitoring network traffic to and from the ERP for suspicious patterns and blocking malicious attempts before they even reach the application.

Furthermore, for enhanced identity and access management, many small manufacturers integrate their ERP with external identity providers (IdP) or single sign-on (SSO) solutions. This centralizes user authentication, allows for easier enforcement of multi-factor authentication (MFA), and simplifies user provisioning and de-provisioning across multiple applications, including the ERP. Advanced security information and event management (SIEM) systems can also be integrated to collect and analyze security logs from the ERP alongside other network devices, providing a holistic view of potential threats and enabling faster incident response. This strategic integration of dedicated cybersecurity tools with your ERP dramatically strengthens your overall security posture, proving that securing your data with ERP for small manufacturing operations is most effective when part of a comprehensive, integrated defense strategy.

Cloud vs. On-Premise ERP: Security Considerations for Small Manufacturers

When small manufacturing operations consider implementing an ERP system, one of the fundamental decisions involves choosing between a cloud-based solution and an on-premise deployment. While both options offer the core benefits of ERP, their security implications and responsibilities differ significantly. Understanding these differences is crucial for making an informed choice that aligns with your specific resources, expertise, and risk tolerance when considering securing your data with ERP for small manufacturing operations.

On-premise ERP means that the software and all its associated data are hosted on servers located within your own facility. This gives you absolute control over the hardware, network, and security configurations. However, this control comes with significant responsibility. Your business becomes entirely responsible for managing all aspects of security: physical security of servers, network security, regular software updates, patch management, data backups, disaster recovery, and hiring or contracting the necessary IT expertise. For many small manufacturers, the cost and complexity of maintaining enterprise-grade security for an on-premise system can be prohibitive, often leading to overlooked vulnerabilities and increased risk.

Cloud-based ERP, on the other hand, means the software and data are hosted and managed by a third-party provider on their remote servers. This model fundamentally shifts the security burden. Reputable cloud ERP providers invest heavily in cybersecurity, employing dedicated security teams, advanced infrastructure, robust encryption, geo-redundant backups, and adherence to various compliance standards (e.g., ISO 27001, SOC 2). While you retain responsibility for user access management and data integrity within the application, the provider handles the underlying infrastructure security, patching, and disaster recovery. For small manufacturers, cloud ERP often provides access to a higher level of security expertise and infrastructure than they could afford or manage internally, making it a compelling option for securing your data with ERP for small manufacturing operations without the heavy IT overhead. However, it’s essential to carefully vet potential cloud providers and understand their security practices, service level agreements (SLAs), and data privacy policies.

The Cost of Inaction: Why Investing in ERP Data Security is Crucial

For small manufacturing operations, the initial investment in an ERP system, particularly one with advanced security features, might seem substantial. There’s often a temptation to cut corners or postpone upgrades, especially when facing tight budgets. However, it’s imperative to consider the far greater “cost of inaction” – the potential financial, reputational, and operational repercussions of failing to adequately secure your data. In today’s threat landscape, this isn’t a hypothetical risk; it’s a very real and present danger that can easily outweigh any upfront savings.

The financial costs of a data breach for a small business can be staggering. These include immediate expenses like forensic investigations to determine the extent of the breach, legal fees, regulatory fines (which can run into the tens of thousands or even millions for privacy violations), and public relations efforts to manage reputational damage. Furthermore, there are operational costs such as system downtime, lost production, customer churn due to eroded trust, and the resources diverted from core business activities to address the fallout. In the worst-case scenarios, a significant breach can lead to permanent business closure, a fate that disproportionately affects smaller enterprises lacking the deep pockets to absorb such shocks.

Beyond the monetary impact, the damage to a small manufacturer’s reputation can be devastating and long-lasting. Trust is a cornerstone of business relationships, and a data breach signals a failure to protect sensitive information, whether it’s customer data, proprietary designs, or supply chain details. This can lead to lost contracts, difficulty attracting new clients, and a tarnished brand image that takes years, if ever, to rebuild. Therefore, viewing the investment in an ERP, specifically for its data security capabilities, as an essential insurance policy rather than an optional expense is critical. Securing your data with ERP for small manufacturing operations isn’t just about protecting your digital assets; it’s about safeguarding your entire business against existential threats and ensuring long-term viability in a competitive, risk-filled world.

Choosing the Right ERP for Data Security: Key Features to Look For

Selecting an ERP system is a significant decision for any small manufacturing operation, and when data security is a primary concern, the choice becomes even more critical. Not all ERP solutions offer the same level of security features or commitment to data protection. Therefore, a careful evaluation process is essential to ensure that the chosen system truly enhances your cybersecurity posture. Focusing on specific security-centric functionalities will help you make an informed investment in securing your data with ERP for small manufacturing operations.

Firstly, prioritize ERP solutions that offer robust multi-factor authentication (MFA) and strong password policies. MFA adds an essential layer of security by requiring users to verify their identity through at least two different methods (e.g., a password and a code from a mobile app), drastically reducing the risk of unauthorized access even if passwords are compromised. Beyond basic access, look for granular, role-based access control that allows you to define precise permissions for every user, ensuring the principle of least privilege is always applied.

Secondly, investigate the ERP’s approach to data encryption. Ensure the system encrypts data both at rest (on servers) and in transit (during transmission). Ask about the encryption standards used (e.g., AES-256) and how encryption keys are managed. Comprehensive audit trails and activity logging are also non-negotiable; the system should provide detailed records of all user actions, data modifications, and security events, crucial for accountability and incident response. Thirdly, consider the provider’s disaster recovery and backup strategy, especially for cloud-based ERPs. What are their recovery time objectives (RTOs) and recovery point objectives (RPOs)? How frequently are backups performed, and where are they stored? Finally, inquire about the ERP vendor’s security certifications and compliance adherence (e.g., ISO 27001, SOC 2, industry-specific standards). A vendor committed to these benchmarks demonstrates a dedication to high security standards, providing an additional layer of assurance for securing your data with ERP for small manufacturing operations.

Implementation Best Practices for Secure ERP Deployment

The journey to securing your data with ERP for small manufacturing operations doesn’t end with choosing the right software; proper implementation is equally crucial. Even the most secure ERP system can be undermined by poor setup or configuration. A strategic and meticulous approach to deployment will maximize the security benefits of your new system and help you avoid common pitfalls that could expose your valuable data. Think of it as carefully laying the foundation for a secure digital fortress.

Firstly, plan meticulously with a security-first mindset. Before any software installation begins, conduct a thorough security assessment of your existing infrastructure and data. Identify what sensitive data resides where, who needs access, and what current vulnerabilities exist. Use this information to inform your ERP configuration, ensuring security policies are baked into the design from day one, not added as an afterthought. Work closely with your ERP vendor or implementation partner to understand and leverage all available security features.

Secondly, configure user access and permissions rigorously from the outset. Avoid granting broad administrative privileges unnecessarily. Implement the principle of “least privilege,” where users only have the minimum access required to perform their job functions. Test these permissions thoroughly to ensure they work as intended and that no unauthorized access is possible. Thirdly, establish strong authentication mechanisms. This means enforcing complex password policies, mandating multi-factor authentication (MFA) for all users, and integrating with any existing identity management systems you may have. Never use default passwords, and change all initial credentials immediately after installation.

Finally, develop a comprehensive backup and disaster recovery strategy that is tailored to your specific manufacturing context. Even if your ERP system handles automatic backups, understand their frequency, retention policies, and test the recovery process regularly. This proactive testing is essential to ensure that in the event of a data loss or system failure, your business can quickly restore operations. By adhering to these best practices, small manufacturers can significantly enhance their data protection efforts, ensuring that their investment in securing your data with ERP for small manufacturing operations yields maximum security benefits.

Ongoing Maintenance and Updates: Keeping Your ERP Secure

Implementing an ERP system and configuring its security features is a fantastic first step, but it’s not a “set it and forget it” solution. The digital threat landscape is constantly evolving, with new vulnerabilities discovered and new attack methods emerging daily. Therefore, ongoing maintenance, regular updates, and continuous vigilance are absolutely essential for keeping your ERP secure and ensuring your small manufacturing operation remains protected against emerging threats. Neglecting these crucial steps can quickly render even the most robust initial security measures ineffective.

Firstly, regular software updates and patching are paramount. ERP vendors continuously release updates that include security patches to address newly identified vulnerabilities. Ignoring these updates leaves your system exposed to known exploits that cybercriminals are eager to leverage. Whether your ERP is on-premise (requiring your IT team to manage patches) or cloud-based (where the vendor typically handles underlying updates), establish a clear process for applying these updates promptly. For cloud solutions, ensure you understand the vendor’s patching schedule and any impact it might have on your operations.

Secondly, routine security audits and reviews are critical. Regularly review user access permissions to ensure they are still appropriate given changes in roles or employee departures. Audit logs should be reviewed periodically for any suspicious activity or anomalies that might indicate a breach attempt. Consider engaging a third-party cybersecurity expert for periodic penetration testing or vulnerability assessments to identify weaknesses that internal teams might overlook. Thirdly, continuous employee training and awareness must be maintained. As threats evolve, so too must your team’s understanding of social engineering tactics, phishing scams, and secure computing practices. Reinforce the importance of strong password hygiene and multi-factor authentication.

Finally, regularly test your disaster recovery plan. Don’t wait for a real incident to discover your backups are corrupted or your recovery process is flawed. Periodically simulate a disaster scenario to ensure your data can be restored efficiently and effectively. This ongoing commitment to maintenance, updates, and vigilance forms the bedrock of securing your data with ERP for small manufacturing operations over the long term, adapting your defenses to match the ever-changing nature of cyber threats.

Real-World Scenarios: How ERP Protects Against Common Threats

To truly appreciate the value of securing your data with ERP for small manufacturing operations, it’s helpful to consider how these systems specifically mitigate common cybersecurity threats that small businesses frequently face. An ERP isn’t just an abstract security concept; it’s a practical defense mechanism against tangible dangers that could cripple your operations.

Consider the threat of ransomware. A single click on a malicious link can encrypt an entire network, holding your critical data hostage. Without an ERP, your design files, customer lists, and financial records might be scattered across various unprotected servers and individual workstations. If hit by ransomware, recovering this fragmented data would be a nightmare, likely involving paying the ransom or losing years of information. With an ERP, especially a cloud-based one, robust, regular, and geo-redundant backups mean that even if your local network is compromised, your core business data within the ERP can be restored from a recent, clean backup, minimizing downtime and avoiding ransom payments. The centralization also means your critical data isn’t easily spread across endpoints that are often the primary vectors for such attacks.

Another significant threat is the insider threat, whether malicious or accidental. An disgruntled employee might attempt to steal proprietary designs or customer databases, or an honest mistake could lead to the deletion of critical production schedules. In a fragmented system, such actions might go unnoticed for days or weeks. However, an ERP’s detailed audit trails record every user action: who accessed what file, when it was modified, and who deleted a record. This provides immediate visibility into suspicious activities, allowing for swift intervention and forensic investigation. Furthermore, granular access controls prevent most employees from accessing or altering data outside their specific job functions, greatly reducing the scope for both intentional and accidental misuse, thereby proving invaluable for securing your data with ERP for small manufacturing operations against threats originating from within.

Future-Proofing Your Security: ERP and Emerging Threats

The digital landscape is not static; it’s a rapidly evolving battleground where new technologies and new threats emerge constantly. For small manufacturing operations, keeping pace with these changes to ensure data security can feel like an impossible task. However, a modern ERP system, when strategically chosen and maintained, offers a robust platform for future-proofing your security, allowing you to adapt to emerging threats and integrate new protective measures without having to rebuild your entire digital infrastructure.

One major area of emerging threat comes from AI-powered cyberattacks. As artificial intelligence becomes more sophisticated, it’s being leveraged by malicious actors to create highly convincing phishing scams, automate vulnerability scanning, and even launch complex, multi-stage attacks. A well-designed ERP system, particularly one delivered via the cloud, benefits from the continuous security enhancements of its vendor, who often deploy AI and machine learning to detect and neutralize these advanced threats before they reach individual customers. ERPs can also integrate with advanced threat intelligence platforms that use AI to identify and block suspicious IPs and patterns.

Furthermore, the rise of IoT (Internet of Things) devices on the manufacturing floor – smart sensors, connected machinery, automated robots – introduces a new attack surface. While ERPs don’t directly secure individual IoT devices, they can serve as the secure central repository for the data generated by these devices. By bringing IoT data into a protected ERP environment, small manufacturers can ensure this valuable operational intelligence is stored, processed, and analyzed securely, rather than being left vulnerable in isolated, often less secure, IoT platforms. The modular and adaptable architecture of modern ERPs also means they are designed to integrate with future security technologies and compliance standards as they emerge. This inherent flexibility and the continuous investment by ERP vendors in security research and development are crucial for securing your data with ERP for small manufacturing operations against the unknown challenges of tomorrow, ensuring your business remains resilient and protected for years to come.

Conclusion: Empowering Small Manufacturers Through ERP Data Security

In conclusion, the journey to securing your data with ERP for small manufacturing operations is not merely an optional IT upgrade, but a fundamental strategic imperative for survival and growth in the modern digital economy. We’ve explored how small manufacturers face unique and often underestimated data security challenges, from fragmented legacy systems and limited resources to their critical position within broader supply chains. The cost of inaction – in terms of financial penalties, reputational damage, and operational disruption – far outweighs the investment in robust protective measures.

An ERP system emerges as the cornerstone of this protection. By acting as a centralized data hub, it transforms scattered vulnerabilities into a unified, manageable security surface. Its sophisticated features, including granular access control, comprehensive data encryption (at rest and in transit), detailed audit trails, and integrated disaster recovery capabilities, address the most pressing security concerns head-on. Furthermore, an ERP simplifies compliance with evolving regulations, extends security benefits to the entire supply chain, reduces human error through standardized processes, and forms a strong foundation for integrating advanced cybersecurity tools. The choice between cloud and on-premise ERP also presents different security advantages, with cloud often offering small manufacturers enterprise-grade protection without the heavy internal IT burden.

Ultimately, securing your data with ERP for small manufacturing operations is about more than just technology; it’s about empowering your business with resilience, building trust with your customers and partners, and future-proofing your operations against an ever-evolving threat landscape. It’s an investment in the longevity and prosperity of your manufacturing enterprise, ensuring that your valuable digital assets are protected, and your business can continue to innovate, produce, and thrive in the digital age. Don’t let data insecurity be the Achilles’ heel of your ambition; embrace the power of ERP to secure your future.