Hello there! If you’re a small manufacturing business owner or manager, you know that keeping a keen eye on your inventory isn’t just a good idea – it’s absolutely critical. It’s the lifeblood of your operation, directly impacting your production schedules, customer satisfaction, and, ultimately, your bottom line. But let’s be honest, manually tracking every raw material, work-in-progress item, and finished product can feel like an endless uphill battle, especially as your business grows. That’s where Understanding ERP Modules for Small Manufacturing Inventory Tracking becomes not just relevant, but essential for future-proofing your business.

Perhaps you’ve heard the term “ERP” and thought it was only for the behemoths of industry. Or maybe you’ve considered it but felt overwhelmed by the sheer scope. Well, you’re not alone. Many small manufacturers grapple with these thoughts, but the truth is, modern ERP solutions are more accessible, scalable, and tailored than ever before, offering robust tools specifically designed to alleviate the very inventory headaches you’re experiencing. This comprehensive guide will demystify ERP, breaking down the specific modules that are game-changers for inventory tracking within your manufacturing environment.

The Inventory Challenge for Small Manufacturers: Navigating the Complexities

For many small manufacturing businesses, inventory management is often a mix of spreadsheets, intuition, and a frantic scramble when something goes wrong. You might be juggling multiple suppliers, handling various raw materials, tracking components through different stages of production, and managing finished goods waiting for shipment. Each of these steps presents a potential point of failure without a robust system in place. The traditional methods, while perhaps sufficient in the very early days, quickly become bottlenecks that hinder growth and erode profitability.

Think about it: have you ever experienced a production delay because you ran out of a critical component you thought you had in stock? Or perhaps you’ve had capital tied up in excess inventory that’s just sitting on shelves, accumulating storage costs and risking obsolescence. These aren’t just minor inconveniences; they’re direct hits to your operational efficiency and financial health. The lack of real-time visibility and accurate data can lead to poor decision-making, missed opportunities, and a constant state of reactive rather than proactive management. The sheer volume and variety of items in your warehouse demand a more sophisticated approach than what manual systems can offer, highlighting the pressing need for a structured solution for small manufacturing inventory tracking.

What Exactly is ERP? Unpacking Enterprise Resource Planning

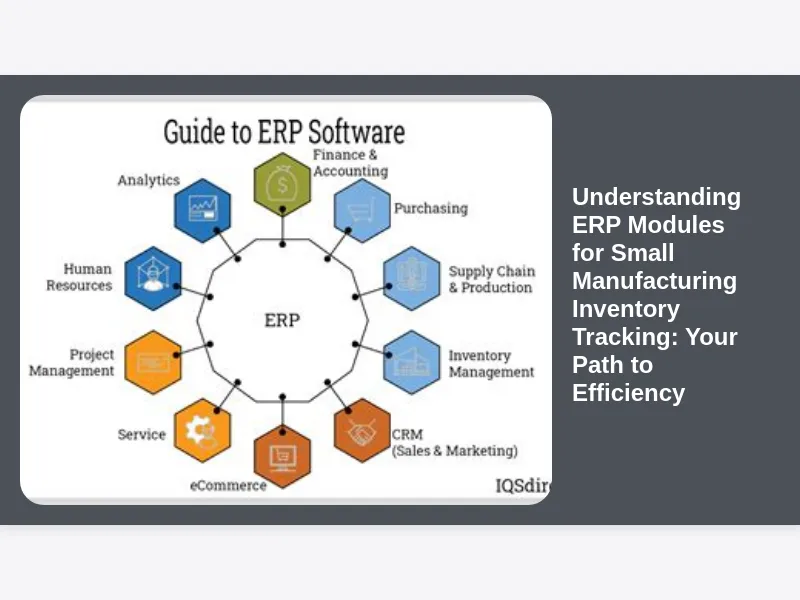

Before we dive into the specific modules, let’s establish a clear understanding of what ERP truly is. ERP stands for Enterprise Resource Planning, and at its core, it’s an integrated software system designed to manage and automate all core business processes, from finance and HR to manufacturing and supply chain operations. Imagine a central nervous system for your entire business – that’s an ERP system. Instead of having separate, disconnected software for accounting, inventory, and sales, an ERP brings them all together into a single, unified database.

This integration is the fundamental power of ERP. It breaks down the data silos that often plague businesses, allowing information to flow seamlessly between departments. For instance, an order placed by a customer in the sales module can immediately trigger a check of finished goods inventory, initiate a production order if stock is low, and update the financial records – all automatically. This holistic approach ensures that everyone in your organization is working with the same, up-to-date information, leading to greater transparency, improved coordination, and significantly better decision-making capabilities. It’s about getting a complete, 360-degree view of your operations, which is incredibly valuable for small manufacturing inventory tracking.

Why Small Manufacturing Needs ERP: Beyond Basic Inventory Management

You might be thinking, “My business is small; do I really need something as comprehensive as ERP?” The answer, increasingly, is yes. While ERP systems were once out of reach for smaller operations due to cost and complexity, today’s cloud-based, modular solutions have made them highly accessible. For a small manufacturer, ERP isn’t just about managing inventory; it’s about building a resilient, scalable, and competitive enterprise. It moves you beyond basic inventory management to strategic operational excellence.

Consider the benefits: you gain real-time data for better forecasting and planning, reduce manual errors and redundant data entry, improve communication across departments, and enhance customer satisfaction through more reliable delivery times. An ERP system helps you optimize your entire production cycle, from the moment a raw material enters your facility to the point a finished product leaves your dock. It provides the insights needed to identify bottlenecks, streamline processes, and make informed decisions that drive growth. For any small manufacturing business looking to expand, innovate, and thrive in a competitive market, adopting an integrated ERP system is no longer a luxury but a strategic imperative, particularly when it comes to refining your small manufacturing inventory tracking capabilities.

Core ERP Modules for Small Manufacturing Inventory Tracking: An Overview

When we talk about Understanding ERP Modules for Small Manufacturing Inventory Tracking, it’s crucial to recognize that an ERP isn’t a single monolithic piece of software, but rather a collection of interconnected modules. Each module is designed to handle a specific business function, but their true power emerges when they work together, sharing data seamlessly. For manufacturing, especially concerning inventory, several key modules stand out as indispensable. These modules collectively provide a comprehensive framework for managing your goods from raw materials to finished products, ensuring accuracy, efficiency, and cost-effectiveness.

We’ll delve into the specific functionalities of each of these core modules, explaining how they contribute to a robust inventory management strategy for small manufacturers. From the direct handling of stock levels to the indirect impact of procurement and financial reporting, each piece plays a vital role in creating a unified system. The goal here is to illustrate how these individual components synergize to give you unparalleled control and visibility over your entire inventory lifecycle, transforming what might currently be a chaotic process into a streamlined and predictable operation.

Module 1: Inventory Management – The Heart of Your Operations

This is arguably the most direct and crucial module when discussing small manufacturing inventory tracking. The Inventory Management module is the central repository for all information related to your stock. It allows you to track every item you possess, whether it’s a tiny screw, a bulky raw material, a partially assembled product, or a completed unit ready for sale. Think of it as your digital warehouse manager, keeping tabs on quantities, locations, and status in real-time. Without this module, the entire ERP ecosystem’s ability to manage stock effectively would crumble.

Key functionalities often include detailed item master data (descriptions, unit of measure, costs), location tracking (bin numbers, warehouse zones, multiple warehouses), batch and lot number tracking for traceability, serial number tracking for high-value items, and various costing methods (FIFO, LIFO, average cost). It automates stock receipts and issues, facilitates internal transfers, and supports physical inventory counts and cycle counting processes. By providing accurate, up-to-the-minute stock levels, this module prevents costly stockouts that halt production and equally expensive overstocking that ties up capital, making it indispensable for the precision required in small manufacturing inventory tracking.

The benefits for a small manufacturer are profound. Imagine knowing the exact quantity of every raw material available before you even start a production run, or precisely how many finished goods you have ready to ship to a waiting customer. This module empowers you to optimize your storage space, reduce waste from expired or obsolete inventory, and most importantly, maintain consistent production flow. It transforms inventory from a static asset into a dynamic, manageable resource, providing the bedrock upon which all other manufacturing processes rely.

Module 2: Production Planning and Scheduling – Optimizing Your Manufacturing Floor

While not directly an “inventory module,” the Production Planning and Scheduling module has an immense, indirect impact on small manufacturing inventory tracking. This module is where you plan what to produce, when to produce it, and how much to produce. It takes customer orders, sales forecasts, and existing inventory levels into account to generate production orders and schedules. It helps you answer critical questions like: Do we have enough raw materials to fulfill this order? When will the required components be ready? What’s our current production capacity?

This module leverages Bills of Material (BOMs) to determine the exact components and quantities needed for each product, and Routings to define the sequence of operations. By integrating with the Inventory Management module, it automatically checks raw material availability before confirming a production schedule, preventing delays caused by missing components. It also tracks work-in-progress (WIP) inventory, offering visibility into products as they move through various stages of your manufacturing process, which is a key part of effective small manufacturing inventory tracking.

For small manufacturers, this integration is invaluable. It ensures that production is aligned with actual demand and available resources, minimizing the risk of overproduction (tying up capital in unsold goods) or underproduction (missing sales opportunities). It helps optimize machine utilization and labor allocation, reducing idle time and improving throughput. By providing a clear, synchronized view of production alongside inventory, it empowers businesses to deliver on time, every time, building customer trust and facilitating sustainable growth.

Module 3: Purchasing and Procurement – Streamlining Your Supply Chain

The Purchasing and Procurement module is another critical piece of the puzzle for efficient small manufacturing inventory tracking. This module manages everything related to acquiring the materials, components, and services your business needs to operate. It’s the gateway through which raw materials enter your inventory, and its efficiency directly impacts your stock levels, costs, and supplier relationships. Without proper procurement, even the best inventory tracking system can be undermined by late deliveries, incorrect orders, or inflated prices.

This module automates the entire purchase-to-pay process. It can generate purchase requisitions based on low inventory alerts from the Inventory Management module or planned production needs from the Production Planning module. It helps create and send purchase orders to vendors, track their status, and manage goods receipts. Furthermore, it supports vendor management, allowing you to store vendor information, track performance, negotiate contracts, and manage pricing. The integration here is key: when goods are received, they are immediately recorded in the Inventory Management module, updating stock levels in real-time.

For small manufacturers, this means less time spent on administrative tasks and more accurate control over inbound inventory. It helps prevent costly emergency orders, takes advantage of bulk discounts, and ensures you have the right materials at the right time. By streamlining the entire procurement cycle, this module directly contributes to maintaining optimal inventory levels, reducing carrying costs, and improving cash flow, all vital aspects of effective small manufacturing inventory tracking.

Module 4: Sales and Order Management – Connecting Customer Demand to Stock

The Sales and Order Management module is where customer demand meets your inventory. This module handles all aspects of the sales process, from receiving customer inquiries and generating quotes to processing sales orders, managing shipments, and invoicing. Its seamless integration with the Inventory Management module is paramount for customer satisfaction and efficient inventory depletion. It bridges the gap between what your customers want and what you currently have or can produce, forming a crucial link in small manufacturing inventory tracking.

When a customer places an order, the Sales and Order Management module immediately checks available inventory. It can provide real-time “available-to-promise” dates, allowing you to confirm delivery schedules accurately and avoid over-promising. If an item is not in stock, the system can automatically flag it for production or procurement, linking directly to the Production Planning and Purchasing modules. Once an order is shipped, the system automatically adjusts inventory levels, ensuring that stock counts are always current and reflecting actual sales.

For small manufacturers, this integration translates into improved order fulfillment rates, fewer shipping errors, and enhanced customer satisfaction. It prevents situations where sales teams commit to orders for which inventory doesn’t exist, leading to frustrated customers and damaged reputation. By providing a clear, integrated view of sales alongside inventory, this module enables precise demand forecasting and better strategic planning, optimizing the entire sales-to-delivery cycle and making your small manufacturing inventory tracking more responsive to market needs.

Module 5: Warehouse Management (WMS) – Advanced Inventory Movement and Storage

While some small manufacturers might start with basic inventory tracking, as operations grow and complexity increases, the functionalities of a dedicated Warehouse Management System (WMS) module become increasingly beneficial, even if it’s a subset of full WMS features within the ERP. This module focuses on optimizing the physical movement and storage of goods within your warehouse. It goes beyond simply knowing what you have to knowing exactly where it is, how it got there, and the most efficient way to retrieve it, significantly enhancing small manufacturing inventory tracking.

A WMS module helps manage receiving goods, putaway strategies (determining the best location for new stock), picking and packing processes for outbound orders, and shipping. It often utilizes barcode scanning or RFID technology for accurate and rapid data capture, reducing manual errors and speeding up operations. Features like batch picking, wave picking, and directed putaway can dramatically improve warehouse efficiency. It also tracks inventory by specific locations down to the bin level, optimizing space utilization and reducing search times.

For a small manufacturer experiencing growth, implementing WMS functionalities can lead to substantial improvements in efficiency and accuracy. It reduces labor costs associated with manual searching and counting, minimizes picking errors, and ensures faster order fulfillment. This enhanced control over physical inventory translates directly into improved accuracy in your ERP’s overall inventory counts, providing a more reliable foundation for production planning and sales commitments, thereby refining your small manufacturing inventory tracking capabilities considerably.

Module 6: Quality Management – Ensuring Product Excellence and Traceability

The Quality Management module, though not directly managing inventory counts, plays a critical supporting role in small manufacturing inventory tracking by ensuring the integrity and usability of your stock. Poor quality can lead to scrap, rework, customer returns, and ultimately, unsellable inventory, all of which incur significant costs and disrupt production. This module helps you maintain product excellence from raw material receipt through to final product shipment.

This module allows you to define quality inspection points at various stages: incoming raw materials, in-process production, and finished goods. It can trigger inspections based on vendor, lot number, or specific product characteristics. If materials fail inspection, the system can automatically quarantine them, preventing them from entering production or being shipped, thereby safeguarding your main inventory. It also facilitates corrective and preventive actions (CAPA) and manages non-conformance reports, helping identify and rectify root causes of quality issues. Crucially for manufacturing, it often provides full traceability, allowing you to track which batch of raw materials went into which finished product, invaluable for recalls or quality audits.

For small manufacturers, this means less waste and rework, which directly reduces the amount of inventory that needs to be written off or disposed of. It ensures that only quality materials are used in production, leading to better final products and fewer customer complaints. By integrating quality checks with inventory movements, you gain tighter control over your stock’s usability and value, making your small manufacturing inventory tracking not just about quantity, but also about the quality and value of your holdings.

Module 7: Financial Management and Accounting – The Monetary Pulse of Your Inventory

The Financial Management and Accounting module is the backbone that ties all operational activities back to your business’s financial health. For small manufacturing inventory tracking, this module is essential because inventory isn’t just a collection of items; it’s a significant asset on your balance sheet and a major component of your cost of goods sold (COGS). Accurate inventory valuation directly impacts your profitability, tax obligations, and overall financial reporting.

This module handles all financial transactions related to inventory: recording the cost of purchased raw materials, calculating the cost of work-in-progress, valuing finished goods, and recognizing the cost of goods sold when products are shipped. It supports various inventory costing methods (e.g., FIFO, LIFO, average cost) and automates the creation of journal entries for inventory movements. Furthermore, it manages accounts payable for supplier invoices and accounts receivable for customer payments, ensuring a complete financial picture of your manufacturing operations.

For small manufacturers, the integration of inventory with financials is a game-changer. It eliminates the need for manual reconciliation between operational inventory records and accounting ledgers, reducing errors and saving significant time during month-end closings. It provides real-time insights into inventory costs, helping you understand true product profitability and make informed pricing decisions. By automatically reflecting inventory value and COGS, this module provides a precise monetary pulse of your stock, making your small manufacturing inventory tracking fully auditable and financially transparent.

Integrating ERP Modules: The Power of a Unified System for Inventory Tracking

We’ve explored individual ERP modules, each playing a critical role in some aspect of small manufacturing inventory tracking. However, the true power and transformative potential of an ERP system lie not in these modules in isolation, but in their seamless integration. Imagine a well-oiled machine where every gear meshes perfectly, allowing for smooth, efficient operation. That’s what an integrated ERP system offers for your manufacturing business. It’s the difference between having disparate tools and having a comprehensive toolkit that works as one.

This integration means that data entered in one module instantly updates relevant information across all other connected modules. For example, when a purchase order is generated in the Procurement module, the system can automatically update expected inventory receipts in the Inventory Management module. When finished goods are produced and booked into inventory via the Production Planning module, the Financials module immediately updates inventory asset values and begins tracking the cost of goods. Similarly, a sales order placed in the Sales module can trigger a stock check, reserve inventory, and if necessary, initiate a production order, with all these actions reflected across the entire system.

For small manufacturers, this unified approach is revolutionary. It eliminates data silos, preventing different departments from working with outdated or conflicting information. It drastically reduces manual data entry and the associated errors, freeing up valuable staff time for more strategic tasks. Most importantly, it provides a single source of truth for all business data, enabling real-time visibility into your operations, from raw material availability to financial performance. This holistic view is crucial for making swift, informed decisions, especially when managing the complexities of small manufacturing inventory tracking and ensures your business operates with maximum efficiency and accuracy.

Overcoming Common Challenges in ERP Implementation for Small Manufacturers

Embarking on an ERP implementation journey, especially for small manufacturing inventory tracking, can seem daunting, and it’s certainly not without its challenges. Many small businesses hesitate due to perceived obstacles, but understanding these common hurdles upfront can help you prepare and mitigate risks. It’s not about avoiding challenges, but about strategically addressing them to ensure a successful transition and maximize your return on investment.

One of the most significant concerns is often the cost. ERP systems, even those tailored for small businesses, represent a substantial investment in software, hardware (if on-premise), implementation services, and training. It’s crucial to conduct a thorough cost-benefit analysis and recognize that while the upfront cost might be high, the long-term savings in efficiency, reduced errors, and improved decision-making often far outweigh this initial outlay. Another hurdle is resistance to change from employees who are comfortable with existing, albeit inefficient, manual processes. Effective change management, including clear communication, comprehensive training, and demonstrating the benefits of the new system, is vital to garnering buy-in and ensuring smooth adoption.

Furthermore, data migration from legacy systems (often spreadsheets or outdated software) can be complex and time-consuming, requiring meticulous planning and execution to ensure data accuracy. Choosing the right ERP vendor and solution itself is also a critical challenge, requiring careful evaluation of features, industry fit, scalability, and support. By addressing these challenges proactively with a clear strategy, dedicated resources, and a focus on incremental adoption, small manufacturers can successfully navigate implementation and unlock the powerful benefits of an integrated system for their small manufacturing inventory tracking.

Choosing the Right ERP Solution for Your Small Manufacturing Business

Selecting the ideal ERP solution is a pivotal decision that will profoundly impact your small manufacturing inventory tracking and overall operational efficiency for years to come. With a multitude of options available, it’s easy to feel overwhelmed. However, by focusing on key factors tailored to the unique needs of a small manufacturing business, you can narrow down your choices and find a system that truly aligns with your goals and budget. This isn’t just about picking software; it’s about finding a strategic partner for your growth.

First and foremost, consider your specific industry. Many ERP solutions offer industry-specific functionalities that cater to the nuances of discrete, process, or mixed-mode manufacturing. An ERP designed for discrete manufacturing, for example, will have robust support for Bills of Material and routings, which is crucial for accurate small manufacturing inventory tracking. Scalability is another critical factor; choose a system that can grow with your business, accommodating increased transaction volumes, new products, and potential expansion into new markets without requiring a complete overhaul.

Next, evaluate the deployment model: cloud-based (SaaS) or on-premise. Cloud ERP solutions offer lower upfront costs, easier maintenance, and greater accessibility, making them very attractive for small businesses. On-premise solutions provide more control but come with higher infrastructure and IT management overhead. Vendor support and training are also paramount; ensure the vendor provides comprehensive support, training resources, and a good track record with small manufacturing clients. Finally, meticulously compare features against your immediate and future needs, paying close attention to the depth of functionality in the core modules we discussed – Inventory Management, Production Planning, Procurement, and Financials. A thorough selection process ensures you invest in an ERP that genuinely transforms your small manufacturing inventory tracking and supports your long-term success.

The Future of Inventory Tracking: ERP, IoT, and AI in Small Manufacturing

The landscape of small manufacturing inventory tracking is continually evolving, driven by technological advancements that promise even greater efficiency and insight. While an integrated ERP system provides a robust foundation, emerging technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) are poised to take inventory management to unprecedented levels, offering capabilities that once seemed like science fiction. Small manufacturers who embrace these innovations, building upon their ERP foundation, will gain a significant competitive edge.

IoT devices, such as smart sensors and RFID tags, can provide real-time, granular data about the physical location, condition, and movement of inventory items. Imagine sensors on raw materials that automatically update their location in the ERP as they move through the warehouse, or temperature sensors on sensitive components alerting you to environmental changes that could affect their quality. This direct integration of physical assets with your digital ERP system minimizes manual scanning, reduces errors, and provides hyper-accurate, continuous inventory visibility.

Artificial Intelligence, on the other hand, can leverage the vast amounts of data collected by your ERP and IoT devices to provide predictive analytics. AI algorithms can analyze historical sales data, production schedules, supplier lead times, and even external factors like weather patterns to forecast demand with greater accuracy than ever before. This leads to optimized inventory levels, reducing carrying costs and preventing stockouts. AI can also identify patterns in warehouse movements to suggest more efficient putaway and picking strategies. For small manufacturers, integrating these advanced technologies with a solid ERP system means moving beyond reactive inventory management to a truly proactive, intelligent, and highly optimized system, setting a new standard for small manufacturing inventory tracking.

Real-World Benefits: What Small Manufacturers Gain from Integrated ERP

By now, you should have a clearer picture of what ERP is and how its various modules contribute to effective small manufacturing inventory tracking. But let’s consolidate the real-world benefits that a small manufacturing business can expect to gain from implementing an integrated ERP system. These aren’t just theoretical advantages; they translate into tangible improvements in efficiency, profitability, and growth potential, making the investment worthwhile for any forward-thinking manufacturer.

Perhaps the most immediate and impactful benefit is a dramatic increase in inventory accuracy and visibility. No more guessing, no more manual counts that are outdated the moment they’re completed. With real-time data, you know exactly what you have, where it is, and its current status, which virtually eliminates stockouts and reduces excess inventory. This directly leads to significant cost savings by minimizing carrying costs, reducing waste from obsolete stock, and avoiding expensive rush orders. Production schedules become more reliable because you can confidently plan based on confirmed material availability, leading to smoother operations and faster throughput.

Beyond inventory, an integrated ERP system fosters better decision-making across the entire organization. With a unified database, all departments operate with the same, accurate information, improving coordination between sales, production, purchasing, and finance. This leads to enhanced customer satisfaction through more reliable delivery promises and fewer order errors. Ultimately, ERP provides the foundation for sustainable growth, enabling small manufacturers to scale their operations efficiently, respond rapidly to market changes, and maintain a competitive edge in a dynamic business landscape. The transformation in small manufacturing inventory tracking alone is often enough to justify the entire endeavor.

Conclusion: Embracing ERP for Sustainable Growth and Precise Inventory Management

As we’ve explored, Understanding ERP Modules for Small Manufacturing Inventory Tracking is far more than just learning about software features; it’s about recognizing a strategic pathway to operational excellence. The journey from fragmented spreadsheets and manual processes to a fully integrated ERP system represents a fundamental shift in how your small manufacturing business operates. It’s a move from reactive management to proactive strategy, from guesswork to data-driven decisions, and from potential chaos to streamlined efficiency.

The core modules we’ve dissected – from Inventory Management, Production Planning, and Procurement to Sales, Quality, and Financials – each play a vital role, but their true power emerges when they are seamlessly integrated. This unification provides a single source of truth for your data, eliminates redundancies, reduces errors, and gives you real-time visibility into every aspect of your inventory and beyond. For the small manufacturer, this means not just better inventory control, but optimized production, stronger supplier relationships, happier customers, and a healthier bottom line.

While the implementation journey presents its own set of challenges, the long-term benefits of embracing an ERP solution are undeniable. It equips your business with the tools needed to navigate the complexities of modern manufacturing, manage growth sustainably, and stay competitive. If you’re currently struggling with inventory inaccuracies, production delays, or a lack of visibility across your operations, it’s time to seriously consider how a modern ERP system can transform your business. It’s an investment not just in technology, but in the future, precision, and sustained success of your small manufacturing enterprise.