For small manufacturing businesses, the journey from raw materials to a gleaming finished product is a complex dance. Every step, from sourcing to production, and ultimately to the delivery of finished goods, requires precision, coordination, and an eagle eye on efficiency. Yet, many small manufacturers find themselves wrestling with manual processes, disconnected spreadsheets, and a constant guessing game when it comes to their finished goods inventory. This struggle isn’t just an inconvenience; it can lead to stockouts, overstocking, production delays, and ultimately, lost revenue and customer dissatisfaction.

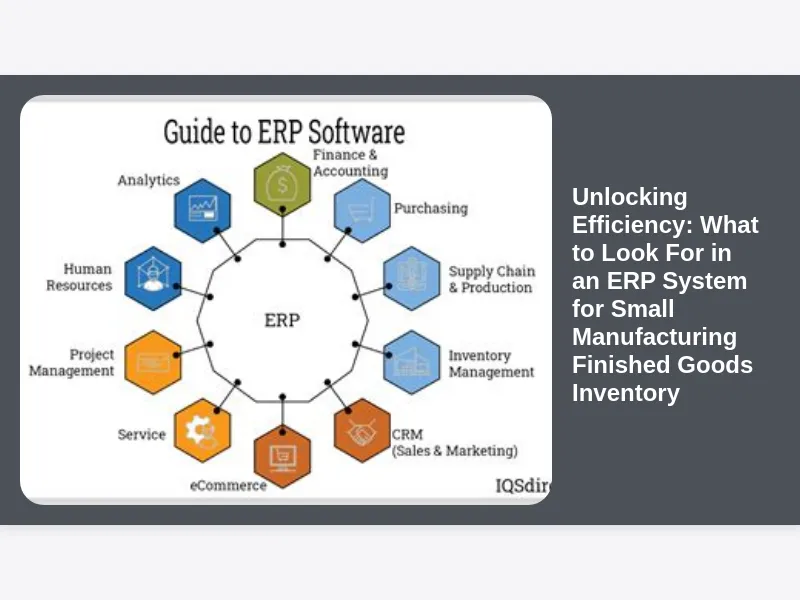

Imagine a world where you know exactly how many finished products you have, where they are, and when they’ll be ready for shipment. Picture being able to forecast demand accurately, schedule production seamlessly, and trace every item back to its origin with a few clicks. This isn’t a pipe dream; it’s the reality an effective Enterprise Resource Planning (ERP) system can deliver. For small manufacturers, especially those focused on finished goods, choosing the right ERP isn’t just about software; it’s about investing in the future of your business. But with so many options out there, what to look for in an ERP system for small manufacturing finished goods inventory becomes the million-dollar question. This comprehensive guide will walk you through the essential considerations, helping you navigate the complexities and make an informed decision that propels your manufacturing operation forward.

Understanding the Unique Inventory Challenges of Small Manufacturers

Small manufacturing businesses operate in a unique ecosystem, often characterized by lean teams, limited budgets, and a need for agility. Unlike larger enterprises with dedicated departments and vast resources, small manufacturers frequently have individuals wearing multiple hats, making efficient processes not just beneficial but absolutely critical for survival and growth. Their finished goods inventory isn’t just a number on a spreadsheet; it represents invested capital, production effort, and the promise of future sales.

The challenge intensifies when you consider the common pitfalls: insufficient capital to absorb large inventory errors, a higher impact of stockouts on customer relationships, and the difficulty in scaling operations without robust, automated systems. Many small businesses start with basic accounting software or even simple spreadsheets, which, while adequate for initial stages, quickly become bottlenecks as the business grows. These rudimentary tools simply can’t provide the real-time visibility, advanced analytics, or integrated functionality required to truly optimize finished goods inventory management. Therefore, a targeted approach to selecting an ERP that addresses these specific constraints is paramount.

Core Inventory Management Capabilities: The Absolute Essentials for Finished Goods

At its heart, any ERP system worth its salt for a small manufacturer must excel at core inventory management, especially when it comes to finished goods. This isn’t about fancy bells and whistles; it’s about the foundational elements that ensure you always know what you have, where it is, and what its status is. Accurate finished goods inventory counts are non-negotiable, acting as the bedrock for all other operational decisions, from sales commitments to production planning. Without this fundamental accuracy, everything else crumbles.

Beyond simple counting, the system must provide robust tracking features. This means the ability to monitor finished goods from the moment they complete their journey on the production line until they leave your facility in a customer’s hands. Features like perpetual inventory updates, which automatically adjust inventory levels as items are produced, sold, or moved, are crucial. Additionally, look for systems that support multiple inventory locations, whether that’s different warehouses, a staging area, or even consignment inventory. The capacity to handle these core functions efficiently and accurately is the first, most critical step in determining what to look for in an ERP system for small manufacturing finished goods inventory.

Real-time Visibility and Accuracy: Knowing What You Have, When You Have It

Imagine the frustration of promising a customer a delivery date, only to find out later that the finished goods you thought were in stock actually aren’t, or are stuck in a quality hold. This is precisely the kind of scenario that real-time visibility aims to eliminate. For a small manufacturer, having an accurate, up-to-the-minute view of your finished goods inventory isn’t a luxury; it’s a strategic imperative. It empowers you to make confident commitments to customers, optimize your warehouse operations, and respond quickly to unexpected changes in demand or supply.

A robust ERP system for finished goods inventory will update stock levels instantaneously as transactions occur—whether it’s an item being received from production, picked for an order, or shipped out. This means no more relying on outdated spreadsheets or manual counts that can be hours or even days old. Real-time data also extends to understanding the exact location of items within your warehouse, their status (e.g., available, on hold, allocated), and their historical movement. This level of granularity not only boosts efficiency but significantly reduces the risk of errors, disputes, and lost products, directly impacting your bottom line and customer satisfaction.

Production Planning and Scheduling Integration: Connecting Inventory to the Shop Floor

The connection between your production line and your finished goods inventory is symbiotic. One cannot function optimally without the other. For a small manufacturing business, an ERP system that seamlessly integrates production planning and scheduling with finished goods inventory management is a game-changer. It means that production orders aren’t created in a vacuum; they’re directly informed by current inventory levels, forecasted demand, and customer order backlogs. This integration ensures that you’re producing what’s needed, when it’s needed, without over-producing or facing unexpected shortages.

Consider the benefits: production schedules become more realistic and achievable, minimizing downtime and maximizing throughput. As finished goods roll off the line, their completion can automatically trigger updates in inventory, making them immediately available for allocation or shipment. This eliminates manual data entry, reduces human error, and ensures that your sales team has an accurate picture of what’s available to sell. When evaluating what to look for in an ERP system for small manufacturing finished goods inventory, prioritizing this tight integration between the factory floor and the warehouse is essential for maintaining a smooth, efficient operation.

Material Requirements Planning (MRP) for Finished Goods: Ensuring Components are Ready

While the focus here is on finished goods, it’s impossible to manage them effectively without considering the components and raw materials that go into making them. This is where Material Requirements Planning (MRP) functionality within an ERP system becomes incredibly valuable, even for small manufacturers. MRP helps you plan your procurement and production activities by looking at your finished goods demand (from sales orders, forecasts, or safety stock requirements) and working backward to determine what materials and sub-assemblies are needed, and when.

A good MRP module will analyze your Bills of Material (BOMs), current inventory levels of raw materials and work-in-progress, and your production capacity to generate a detailed plan. This ensures that you have the right components at the right time to meet your finished goods production schedule, preventing costly delays and rush orders. For a small manufacturing operation, this means less capital tied up in excess raw materials and fewer instances of production being halted due to a missing part. It’s an indirect but powerful driver of finished goods availability and efficiency.

Traceability and Lot Tracking: Critical for Quality and Compliance

In many manufacturing sectors, especially those dealing with food, pharmaceuticals, medical devices, or high-value components, traceability is not just a best practice; it’s often a regulatory requirement. Even for other industries, the ability to track finished goods back to their raw materials and through every step of the production process offers immense value in terms of quality control, recall management, and customer trust. An ERP system must provide robust lot or serial number tracking capabilities for your finished goods.

This means being able to assign unique identifiers to batches or individual units of your finished products and record every relevant detail associated with them—production date, expiration date, ingredients, specific raw material lots used, quality inspection results, and even the equipment or operators involved. Should a quality issue arise or a recall become necessary, this level of traceability allows you to pinpoint affected products quickly and accurately, minimizing impact and ensuring compliance. When considering what to look for in an ERP system for small manufacturing finished goods inventory, strong traceability features are a non-negotiable for safeguarding your brand and meeting industry standards.

Quality Control and Inspection Integration: Maintaining High Standards

For small manufacturers, maintaining consistent product quality is paramount to building a strong reputation and securing repeat business. An ERP system that integrates quality control processes directly into the finished goods inventory workflow can significantly streamline operations and ensure that only products meeting your high standards are shipped to customers. This goes beyond simple traceability and delves into the active management of quality checks.

Look for features that allow you to define inspection points, create quality plans, record inspection results, and manage non-conforming products. For example, finished goods might automatically be placed into a “quality hold” status upon completion until a final inspection is passed. Only then would they be moved to “available for sale.” The system should also facilitate the documentation of defects, reworks, and dispositions, providing a comprehensive audit trail. Integrating quality control directly into your ERP for finished goods inventory ensures that quality isn’t an afterthought but an intrinsic part of your operational process, directly contributing to customer satisfaction and reducing costly returns.

Sales Order Management and Fulfillment: From Order to Delivery

The ultimate purpose of finished goods inventory is to fulfill customer orders. Therefore, the ERP system’s ability to seamlessly integrate sales order management with inventory and fulfillment processes is absolutely critical. For a small manufacturer, this means that when a customer places an order, the system should immediately check finished goods availability, allocate stock, and kick off the necessary picking, packing, and shipping processes.

An effective ERP will provide a complete view of the order-to-cash cycle. From initial sales inquiry and quote generation to order entry, inventory allocation, picking instructions for the warehouse, shipping label generation, and ultimately, invoicing. This integrated approach minimizes manual data entry, reduces errors in order fulfillment, and speeds up delivery times, which are all vital for customer satisfaction and competitive advantage. When evaluating what to look for in an ERP system for small manufacturing finished goods inventory, pay close attention to how well it handles the entire sales order lifecycle, ensuring a smooth handoff from your sales team to your operations team.

Demand Forecasting and Planning Tools: Predicting Future Needs

For small manufacturers, accurately predicting future demand for finished goods is one of the most challenging yet impactful aspects of inventory management. Over-forecast and you tie up valuable capital in excess inventory; under-forecast and you risk stockouts, lost sales, and disgruntled customers. An ERP system equipped with robust demand forecasting and planning tools can significantly mitigate these risks, moving you from reactive to proactive inventory management.

These tools leverage historical sales data, seasonal trends, promotional activities, and even external market indicators to generate more accurate predictions of future demand. While no forecast is 100% accurate, a good ERP will provide various forecasting models and allow you to adjust parameters based on your specific business knowledge. This intelligence then feeds directly into your production planning and procurement, helping you optimize inventory levels for finished goods, reduce carrying costs, and improve customer service by ensuring products are available when needed. Investing in these predictive capabilities is a smart move for any small manufacturer looking to sharpen their competitive edge.

Scalability for Growth: Future-Proofing Your Investment

Small manufacturers rarely stay small if they’re doing things right. Growth is the ultimate goal, and your ERP system should be an enabler of that growth, not a constraint. When considering what to look for in an ERP system for small manufacturing finished goods inventory, scalability is a crucial long-term factor. A system that works perfectly for your current 10-person operation might crumble under the weight of increased transactions, more complex product lines, additional warehouses, or a larger workforce in just a few years.

An ERP designed with scalability in mind can grow with you. This might mean the ability to easily add more users, integrate new modules (like CRM or advanced analytics), handle a greater volume of data and transactions, or expand to multiple production facilities or sales channels without requiring a complete system overhaul. Look for cloud-based solutions, which inherently offer more flexibility and easier scaling compared to on-premise systems that require significant hardware upgrades. Choosing a scalable ERP protects your initial investment and ensures that your system remains a valuable asset as your business evolves and expands its manufacturing footprint.

Integration with Existing Systems: Harmonizing Your Tech Stack

No business operates in a vacuum, and your ERP system is unlikely to be the only piece of software in your technology stack. For small manufacturers, it’s common to have existing systems for accounting, CRM, e-commerce, or specialized machinery control. The ability of your chosen ERP to integrate seamlessly with these existing tools is incredibly important to avoid data silos, manual double-entry, and operational inefficiencies. A fragmented tech landscape can negate many of the benefits an ERP aims to deliver.

When evaluating an ERP for finished goods inventory, inquire about its integration capabilities. Does it offer native integrations with popular accounting software like QuickBooks or Xero, or e-commerce platforms like Shopify? Does it have an open API (Application Programming Interface) that allows for custom integrations with specialized machinery or industry-specific tools? Harmonizing your various systems ensures that data flows freely across your organization, providing a single source of truth and a comprehensive view of your operations. This minimizes errors, saves countless hours of manual reconciliation, and ultimately makes your entire business more efficient.

User-Friendliness and Training: Getting Your Team On Board

Even the most powerful ERP system is useless if your team can’t or won’t use it effectively. For small manufacturing businesses, where resources are often stretched thin, user-friendliness and the availability of adequate training are paramount. Complex, unintuitive software can lead to resistance from employees, slow adoption rates, data entry errors, and a failure to realize the system’s full potential. You want your team to embrace the new system, not dread it.

When assessing what to look for in an ERP system for small manufacturing finished goods inventory, pay close attention to the user interface (UI) and user experience (UX). Is it logical and easy to navigate? Are common tasks straightforward? Does it offer customizable dashboards that present relevant information to different roles (e.g., warehouse manager, production supervisor)? Furthermore, inquire about the vendor’s training programs, documentation, and ongoing support resources. A well-designed system, coupled with accessible training, ensures that your employees quickly become proficient, fostering higher data accuracy, increased productivity, and a smoother transition to the new way of working.

Cost Considerations and ROI: Balancing Budget with Benefits

For small manufacturers, budget constraints are a very real factor in any significant technology investment. While the benefits of an ERP system for finished goods inventory can be substantial, it’s crucial to carefully evaluate the total cost of ownership (TCO) against the potential return on investment (ROI). This isn’t just about the upfront software licensing or subscription fees; it includes implementation costs, training, customization, ongoing maintenance, and potential hardware upgrades if choosing an on-premise solution.

Be transparent about your budget with potential vendors and seek clear, itemized quotes. Don’t be swayed solely by a low initial price; a cheaper system might lack critical features, require extensive customization, or come with hidden costs down the line. Instead, focus on the value proposition: how will the ERP save you money by reducing stockouts, minimizing waste, improving efficiency, and boosting customer satisfaction? Calculate the potential ROI by quantifying these savings and revenue gains against the TCO. A well-chosen ERP for finished goods inventory should pay for itself multiple times over through improved operational efficiency and strategic advantages.

Vendor Support and Implementation Services: A Successful Partnership

Implementing an ERP system, even for a small manufacturer, is a significant undertaking. It’s not just about installing software; it’s about transforming business processes. Therefore, the quality of vendor support and implementation services is just as important as the features of the software itself. You’re not just buying a product; you’re entering into a long-term partnership with the vendor.

A good vendor will offer a structured implementation plan, guide you through data migration, provide comprehensive training, and be responsive to your questions and challenges both during and after rollout. Look for vendors with experience specifically in the manufacturing sector and, ideally, with small businesses. Ask about their support channels (phone, email, chat), response times, and the availability of a dedicated account manager. A strong support system can make the difference between a smooth, successful implementation and a frustrating, costly failure. Their commitment to your success is a critical aspect of what to look for in an ERP system for small manufacturing finished goods inventory.

Reporting and Analytics for Informed Decisions: Data-Driven Insights

One of the most powerful advantages an ERP system brings to a small manufacturer is its ability to transform raw data into actionable insights. For finished goods inventory, this means moving beyond simple stock counts to understanding trends, identifying bottlenecks, and making data-driven decisions that optimize your entire operation. A robust ERP should offer comprehensive reporting and analytics capabilities that are easy to access and understand.

Look for customizable dashboards and reports that can provide a holistic view of your finished goods inventory performance. This might include reports on inventory turnover rates, days of supply, carrying costs, slow-moving or obsolete stock, order fulfillment rates, and production variances. The ability to drill down into specific data points and generate ad-hoc reports is also incredibly valuable. With these insights, you can identify areas for improvement, optimize purchasing and production schedules, and ultimately make more strategic decisions that enhance profitability and efficiency across your manufacturing business.

Mobile Access and Cloud-Based Solutions: Flexibility and Accessibility

In today’s fast-paced business environment, flexibility and accessibility are non-negotiable, especially for small manufacturers whose teams might be constantly on the go, whether on the shop floor, in the warehouse, or meeting with clients. This is where mobile access and cloud-based ERP solutions shine. A cloud-based ERP, hosted on remote servers and accessed via the internet, eliminates the need for expensive on-premise hardware and IT infrastructure, significantly reducing upfront costs and ongoing maintenance for small businesses.

Beyond cost savings, cloud ERPs offer inherent scalability, automatic updates, and robust data security provided by the vendor. Mobile access allows your team to manage finished goods inventory, check stock levels, process orders, or update production statuses from any device, anywhere, anytime. This not only boosts productivity but also ensures that critical information is always at your fingertips, enabling quicker decision-making and more responsive operations. When evaluating what to look for in an ERP system for small manufacturing finished goods inventory, prioritizing cloud-based options with strong mobile capabilities is a forward-thinking choice.

Security and Data Protection: Protecting Your Valuable Information

For any business, big or small, data is a valuable asset. For manufacturers, this data includes sensitive information about production processes, inventory levels, customer orders, and financial transactions. Therefore, the security and data protection features of an ERP system are paramount. A data breach or loss can have devastating consequences, not just financially but also for your reputation and compliance standing.

When selecting an ERP for finished goods inventory, inquire thoroughly about the vendor’s security protocols. This includes data encryption, regular backups, disaster recovery plans, access controls, and compliance with relevant data protection regulations (e.g., GDPR, CCPA). For cloud-based solutions, understand their data center security measures, penetration testing practices, and audit reports. Ensure that the system offers robust user authentication and authorization features, allowing you to control who can access and modify different types of information. Trusting your critical business data to an ERP requires absolute confidence in its security framework.

Compliance and Regulatory Requirements: Meeting Industry Standards

Many small manufacturers operate in industries with specific compliance and regulatory requirements. These can range from quality standards (like ISO certifications) to traceability mandates, environmental regulations, or specific reporting structures. Your ERP system must not only support these requirements but ideally, help you proactively meet and manage them, especially concerning your finished goods inventory.

For example, if your industry demands specific lot tracking details, expiry date management, or detailed audit trails for every product movement, the ERP must have these functionalities built-in or be easily configurable to achieve them. The system should simplify the generation of compliance reports, making it easier to pass audits and avoid penalties. Before committing to an ERP, conduct a thorough assessment of your industry’s specific compliance needs and verify that the system can adequately address each one. This foresight is crucial when determining what to look for in an ERP system for small manufacturing finished goods inventory to ensure sustained operations and market access.

Testing and Pilot Programs: Ensuring a Smooth Rollout

Implementing a new ERP system for your finished goods inventory is a significant organizational change. To minimize disruption and ensure a smooth transition, the vendor should support or offer a testing phase or pilot program. This allows your team to familiarize themselves with the new system in a controlled environment, identify potential issues, and refine processes before going live with your entire operation.

A good testing strategy involves simulating real-world scenarios, from receiving finished goods from production to processing sales orders and shipping. It also provides an opportunity to validate data migration, test integrations with other systems, and fine-tune user roles and permissions. By investing time in a thorough testing phase, small manufacturers can catch errors early, gain confidence in the system, and ensure that when the actual go-live occurs, it’s as seamless and effective as possible, setting the stage for long-term success with your new inventory management solution.

The Future of Inventory Management: Emerging Trends and Innovations

The world of manufacturing and inventory management is constantly evolving, driven by technological advancements and changing consumer expectations. When selecting an ERP system for your small manufacturing finished goods inventory, it’s wise to consider not just current needs but also how the system can accommodate future trends. Look for vendors who are investing in innovation and whose platforms are designed to adapt.

Emerging trends like IoT (Internet of Things) for real-time asset tracking, AI and machine learning for more sophisticated demand forecasting and predictive maintenance, and blockchain for enhanced supply chain transparency are becoming more prevalent. While a small manufacturer might not need all these features immediately, choosing an ERP with the potential to integrate with or leverage these technologies in the future provides a significant advantage. This ensures your investment remains relevant and capable of supporting your business as the industry continues to transform, keeping you competitive and agile in a rapidly changing market landscape.

Conclusion: Making the Right Choice for Your Manufacturing Future

Navigating the complexities of finished goods inventory management is a constant challenge for small manufacturers, but the right ERP system can transform these challenges into opportunities. By providing real-time visibility, streamlining production, integrating sales, and offering powerful analytical tools, an ERP empowers you to make smarter decisions, reduce costs, and ultimately deliver a superior product and service to your customers.

The journey to finding the perfect ERP system begins with a clear understanding of your unique business needs and a meticulous evaluation of the available solutions. Remember to prioritize core inventory capabilities, look for seamless integration, consider scalability, and never underestimate the importance of user-friendliness and robust vendor support. This comprehensive guide has hopefully shed light on what to look for in an ERP system for small manufacturing finished goods inventory, arming you with the knowledge to make an informed decision. Investing in the right ERP isn’t just a software purchase; it’s a strategic move that lays the foundation for sustained growth, efficiency, and competitiveness in the dynamic world of manufacturing. Choose wisely, and watch your manufacturing operations soar to new heights.