The hum of machinery, the scent of raw materials transforming into finished goods, the constant pursuit of precision – this is the vibrant world of small manufacturing. For years, the backbone of these operations has often relied on a mix of experience, manual processes, and sometimes, a bit of educated guesswork. While dedication and craftsmanship are invaluable, the modern manufacturing landscape demands more. It calls for agility, real-time visibility, and data-driven decision-making, particularly on the bustling shop floor. This is where Mobile ERP Solutions for Small Manufacturing Floor Management emerge not just as an option, but as a transformative necessity.

Imagine a world where your floor managers, supervisors, and operators aren’t tethered to a desktop computer or shuffling through paper printouts. Envision them empowered with tablets or smartphones, instantly accessing work orders, logging progress, reporting issues, and managing inventory right where the action happens. This isn’t a futuristic dream; it’s the tangible reality offered by mobile-enabled Enterprise Resource Planning (ERP) systems. For small manufacturers grappling with growth, optimization, and staying competitive, embracing such a solution is less about keeping up and more about leapfrogging ahead.

What Exactly is Mobile ERP and Why Does it Matter for Manufacturers?

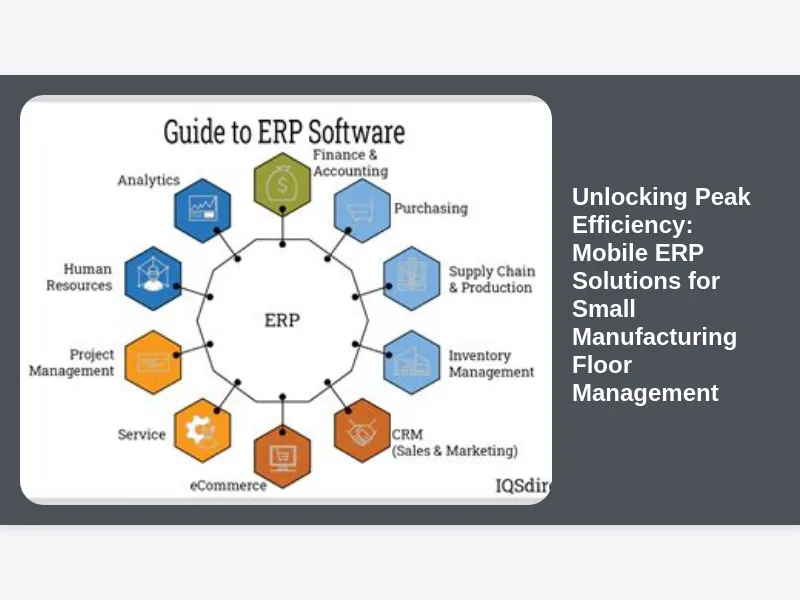

Before we dive deep into its specific applications, let’s clarify what we mean by Mobile ERP. Enterprise Resource Planning (ERP) systems are comprehensive software suites designed to integrate all facets of an operation – from product planning, development, manufacturing, and sales to marketing and human resources. They act as the central nervous system of a business, consolidating data and streamlining processes across departments. A Mobile ERP takes this powerful integration and extends its reach directly to the hands of your workforce, specifically making it accessible and usable on portable devices like smartphones and tablets.

For the manufacturing sector, especially smaller operations, the “mobile” aspect of ERP is revolutionary. Traditional ERP systems, while effective, often required data input from fixed terminals or back-office staff, creating delays and potential for error when information had to be relayed from the shop floor. Mobile ERP solutions for small manufacturing floor management break down these barriers, allowing immediate data capture and access from anywhere within your facility. This immediate feedback loop is critical for dynamic environments where conditions can change rapidly and decisions need to be made on the fly. It transforms an administrative task into an integrated part of the production workflow, fostering a more responsive and efficient operation.

The Unique Challenges of Small Manufacturing Floor Management

Small manufacturing businesses operate with a distinct set of challenges that often differ from their larger counterparts. Resources are typically more constrained, and every dollar and minute count significantly. On the shop floor, these constraints manifest in several critical areas. Manual data entry is rampant, leading to significant time loss, transcription errors, and a frustrating reliance on paper trails that get lost or misfiled. Without a centralized, real-time system, achieving accurate inventory counts becomes a constant battle, resulting in costly stockouts or equally expensive overstocking.

Furthermore, a lack of real-time visibility into production progress means that bottlenecks aren’t identified until they’ve already caused significant delays. When a machine breaks down, or a specific raw material runs low, the information might not reach decision-makers quickly enough, leading to cascading problems throughout the production schedule. Quality control checks can be inconsistent, and compliance tracking becomes an administrative burden rather than an integrated process. These inefficiencies directly impact profitability, delivery times, and ultimately, customer satisfaction. Addressing these pain points effectively is precisely where Mobile ERP Solutions for Small Manufacturing Floor Management offer a compelling path forward.

Real-time Production Tracking at Your Fingertips with Mobile ERP

One of the most immediate and profound benefits of implementing a Mobile ERP system on a small manufacturing floor is the ability to achieve real-time production tracking. Gone are the days of supervisors walking the floor with clipboards, manually noting progress, or waiting for shift reports to compile crucial data. With a mobile ERP, operators can log the start and completion of tasks, report material consumption, or update machine statuses directly from a tablet or smartphone conveniently located at their workstation or carried with them.

This immediate data capture feeds directly into the central ERP system, providing an up-to-the-minute overview of every work order, every machine, and every stage of production. Managers can instantly see which jobs are on schedule, which are falling behind, and which machines are idle or experiencing issues. This level of granular, real-time insight is invaluable for proactive management. It enables quick adjustments to production schedules, reallocation of resources, and timely intervention before minor delays escalate into major disruptions. The ability to monitor every pulse of the production process dramatically enhances responsiveness and control, making Mobile ERP Solutions for Small Manufacturing Floor Management a cornerstone of operational excellence.

Revolutionizing Inventory Management: From Warehouse to Workbench with Mobile ERP

Inventory management is often a make-or-break function for small manufacturers. Too much inventory ties up capital and occupies valuable floor space; too little can halt production and delay customer orders. Traditional inventory methods, often involving manual counts and spreadsheets, are prone to human error and can never truly provide an accurate, up-to-the-minute picture. This is where Mobile ERP shines, offering transformative capabilities for managing materials and finished goods with unprecedented accuracy and efficiency, directly impacting your Mobile ERP Solutions for Small Manufacturing Floor Management.

Imagine your warehouse staff or production operators using a mobile device with barcode or RFID scanning capabilities. They can instantly record incoming raw materials, allocate them to specific bins, track their movement to the production line, and document the consumption during manufacturing. Finished goods can be scanned as they come off the line and moved to storage or shipping, all with a few taps. This eliminates manual data entry, reduces errors, and provides a truly dynamic view of your stock levels. With real-time inventory updates, you can confidently conduct cycle counts, reorder materials precisely when needed, avoid stockouts, and reduce waste from expired or obsolete inventory, ensuring a leaner, more agile operation.

Empowering Your Workforce: Shop Floor Data Collection Made Easy

The success of any technology implementation hinges on user adoption, and Mobile ERP is designed with the shop floor worker in mind. One of its most significant contributions is simplifying shop floor data collection, transforming it from a tedious chore into an intuitive part of the workflow. Instead of filling out paper forms, walking to a desktop terminal, or relaying information verbally, operators can interact with the ERP system directly through their mobile devices.

This empowerment means operators can easily clock in and out of jobs, report on the quantity of parts produced, log scrap or rework, and even input quality check results. The user interfaces of modern Mobile ERP Solutions for Small Manufacturing Floor Management are often designed to be visual, touch-friendly, and straightforward, minimizing training time and maximizing efficiency. By placing the tools for data entry directly in the hands of those who generate the data, you not only improve accuracy and timeliness but also give your workforce a sense of ownership and direct contribution to the overall success of the operation. This shift boosts morale and transforms how work is perceived and managed on the floor.

Boosting Production Efficiency and Throughput with Integrated Mobile Solutions

The ultimate goal for any small manufacturer is to maximize production efficiency and throughput without compromising quality. Achieving this requires precise scheduling, optimal resource allocation, and continuous monitoring. Mobile ERP systems provide the integrated tools necessary to orchestrate these complex elements seamlessly. With real-time data streaming from the shop floor, managers gain immediate insights into machine utilization, operator performance, and material availability.

This comprehensive view allows for dynamic scheduling adjustments, ensuring that bottleneck machines are utilized effectively and that work is distributed optimally across the available workforce and equipment. If a machine goes down, a mobile alert can trigger a rescheduling process almost instantaneously, minimizing downtime. Furthermore, by automating data collection and reducing administrative overhead, operators can spend more time on value-added tasks – actually manufacturing products – rather than on paperwork. The synergistic effect of real-time data, streamlined communication, and responsive planning dramatically boosts overall production efficiency, leading to higher throughput and better adherence to delivery schedules, a critical advantage offered by Mobile ERP Solutions for Small Manufacturing Floor Management.

Quality Control and Compliance Simplified on the Go

Maintaining consistent product quality and adhering to regulatory compliance standards are non-negotiable for manufacturers, regardless of their size. For small manufacturers, managing these critical processes manually can be incredibly burdensome, prone to inconsistencies, and difficult to audit. Mobile ERP solutions provide a robust framework to integrate quality control (QC) directly into the production workflow, making it simpler, more consistent, and trackable.

Imagine your QC inspectors or even line operators conducting checks directly on a mobile device. They can follow digital checklists, capture images of defects, input measurements, and flag non-conforming items instantly. This data is immediately recorded in the ERP system, creating a permanent, auditable record. If a batch fails a quality check, the system can automatically trigger alerts, quarantine inventory, and initiate corrective actions. For compliance, the system can track materials, processes, and finished goods against regulatory requirements, providing comprehensive audit trails and ensuring that your small manufacturing operation meets industry standards effortlessly. This proactive approach significantly reduces rework, waste, and the risk of costly recalls, embodying the comprehensive benefits of Mobile ERP Solutions for Small Manufacturing Floor Management.

The Power of Cloud-Based Mobile ERP for Small Manufacturing

When considering Mobile ERP, the conversation inevitably turns to cloud deployment, especially for small manufacturing businesses. The cloud is not just a trend; it’s a paradigm shift that offers significant advantages over traditional on-premise software. For small manufacturers, these benefits are particularly impactful, addressing common budgetary and IT resource constraints. A cloud-based Mobile ERP system is hosted on remote servers and accessed via the internet, meaning you don’t need to invest in expensive hardware, servers, or dedicated IT staff to maintain the system.

This translates to lower upfront costs and a more predictable, often subscription-based, operational expense model, making advanced ERP technology accessible to businesses that previously couldn’t afford it. Furthermore, cloud solutions offer unparalleled accessibility – your team can access the system from anywhere with an internet connection, crucial for mobile functionality on the shop floor. Data security, backups, and system updates are typically handled by the vendor, freeing up your internal resources to focus on manufacturing. The scalability of cloud ERP also means the system can grow seamlessly with your business, accommodating increased users, data, and functionalities without needing a complete overhaul, proving to be an ideal choice for Mobile ERP Solutions for Small Manufacturing Floor Management.

Seamless Supply Chain Visibility: Connecting Your Floor to Your Suppliers

A manufacturing floor doesn’t operate in isolation; it’s a critical node within a larger supply chain. For small manufacturers, maintaining clear visibility across this chain can be challenging, often relying on phone calls, emails, and disparate systems. However, a well-implemented Mobile ERP solution can significantly enhance supply chain visibility, connecting your floor operations not just internally but also outward to your suppliers and customers. This holistic view is paramount for proactive planning and responsiveness.

With real-time inventory data and production schedules captured via mobile devices, your ERP system can provide accurate forecasts for material needs, allowing for better communication and stronger relationships with suppliers. Suppliers can potentially be given limited, secure access to relevant parts of your ERP, such as purchase orders or forecasted demand, enabling them to anticipate your needs and ensure timely deliveries. Conversely, your sales team can provide customers with more accurate lead times, leveraging the up-to-the-minute production status directly from the shop floor. This interconnectedness reduces disruptions, improves material flow, and ultimately strengthens your entire supply chain, making Mobile ERP Solutions for Small Manufacturing Floor Management a crucial enabler of external as well as internal efficiency.

Making Data-Driven Decisions: Analytics and Reporting from the Shop Floor

The true power of any ERP system lies in its ability to transform raw data into actionable intelligence. For small manufacturing, where every decision can have a significant impact, the analytical capabilities of a Mobile ERP are invaluable. By collecting vast amounts of real-time data from every touchpoint on the shop floor – from machine uptime and operator efficiency to material usage and quality control checks – the system creates a rich repository of operational information.

Modern Mobile ERP Solutions for Small Manufacturing Floor Management come equipped with robust reporting and analytics tools, often featuring customizable dashboards. These dashboards can provide a high-level overview of key performance indicators (KPIs) for managers, while also offering the ability to drill down into specific details for granular analysis. You can track metrics like OEE (Overall Equipment Effectiveness), first-pass yield, labor utilization, production costs per unit, and more. This data empowers managers to identify trends, pinpoint inefficiencies, and make informed decisions about process improvements, equipment investments, or training needs. Moving from gut feelings to data-backed strategies is a cornerstone of modern manufacturing competitiveness, and mobile ERP makes this transition accessible and practical for smaller enterprises.

Overcoming Implementation Hurdles: A Smooth Transition to Mobile ERP

For many small manufacturers, the idea of implementing a comprehensive ERP system, especially one with mobile capabilities, can seem daunting. Concerns about complexity, cost, disruption to operations, and user adoption are common. However, with careful planning and the right approach, transitioning to Mobile ERP Solutions for Small Manufacturing Floor Management can be a smooth and highly beneficial process. The key is to approach implementation strategically, breaking it down into manageable steps.

Firstly, a thorough assessment of your current processes and identification of pain points is crucial. This will help define your requirements and select an ERP solution that genuinely addresses your specific needs. Vendor selection is also vital; choose a partner with experience in your industry and with small business implementations. A phased implementation, focusing on critical modules first (e.g., inventory and production tracking), can minimize disruption and allow your team to gradually adapt. Comprehensive training for all users, particularly those on the shop floor, is non-negotiable, emphasizing the benefits and ease of use. Finally, strong change management, including clear communication about why the system is being implemented and how it will improve daily work, will foster user acceptance and ensure a successful transition, paving the way for long-term operational excellence.

Measuring Your ROI: The Tangible Benefits of Mobile ERP for Small Manufacturing

Investing in new technology, particularly something as comprehensive as a Mobile ERP, naturally raises questions about return on investment (ROI). For small manufacturers, demonstrating tangible benefits is crucial to justify the expenditure. Fortunately, Mobile ERP Solutions for Small Manufacturing Floor Management offer a clear path to significant and measurable returns across various facets of the business. The benefits extend beyond mere efficiency gains, impacting profitability, growth potential, and competitive advantage.

Tangible benefits include reduced operational costs through optimized inventory levels (less waste, fewer carrying costs), decreased manual data entry errors, and minimized production downtime. Productivity skyrockets as operators spend more time on manufacturing and less on administrative tasks, and managers can make quicker, more informed decisions. Improved quality control leads to less rework and fewer warranty claims. Enhanced supply chain visibility can result in better supplier relationships and reduced material lead times. Ultimately, these improvements lead to faster order fulfillment, higher customer satisfaction, and the capacity to take on more business without significantly increasing overhead. Documenting these improvements through key performance indicators (KPIs) measured before and after implementation provides a compelling case for the long-term value and substantial ROI of a mobile ERP investment.

Integrating Mobile ERP with Existing Systems: A Holistic Approach

For many small manufacturing businesses, a complete overhaul of all existing systems at once isn’t feasible or desirable. You might have legacy accounting software, a separate CRM, or specialized CAD/CAM systems that are working well. The good news is that modern Mobile ERP Solutions for Small Manufacturing Floor Management are designed with integration in mind. A holistic approach to your technology stack ensures that all systems communicate effectively, eliminating data silos and creating a single source of truth across your organization.

Seamless integration means that data entered on the shop floor via a mobile device can immediately update inventory levels in your accounting system, or trigger a customer service alert in your CRM regarding a production delay. This interconnectedness avoids duplicate data entry, reduces errors, and ensures that every department is working with the most current information. When evaluating Mobile ERP vendors, inquire about their integration capabilities, API (Application Programming Interface) availability, and experience with integrating into common manufacturing and business applications. A well-integrated ERP system acts as the central hub, allowing your specialized systems to continue performing their specific functions while contributing to a unified, efficient, and data-rich operational environment.

Security Considerations in Mobile ERP for Manufacturing Data

In today’s interconnected world, data security is paramount, and this concern is amplified when considering Mobile ERP Solutions for Small Manufacturing Floor Management. Giving employees access to sensitive production, inventory, and potentially customer data on mobile devices raises legitimate questions about safeguarding that information. However, modern ERP systems, especially cloud-based ones, are built with robust security features to protect your valuable business intelligence.

Vendors of reputable cloud ERP solutions invest heavily in data encryption, secure data centers, regular backups, and multi-factor authentication to prevent unauthorized access. For the mobile aspect, it’s crucial to implement strong mobile device management (MDM) policies. This includes features like secure login credentials, automatic logouts, remote wipe capabilities for lost or stolen devices, and limiting data storage on the devices themselves. Role-based access control within the ERP system ensures that employees only see the information relevant to their job functions, further minimizing risk. By understanding these security layers and implementing best practices internally, small manufacturers can confidently leverage the power of mobile technology without compromising the integrity and confidentiality of their critical manufacturing data.

The Future of Small Manufacturing: AI, IoT, and Mobile ERP Synergy

The manufacturing landscape is continuously evolving, with emerging technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) poised to revolutionize operations even further. For small manufacturers utilizing Mobile ERP Solutions for Small Manufacturing Floor Management, these technologies are not distant concepts but rather natural extensions that will enhance the power of their existing systems. The synergy between mobile ERP, AI, and IoT will unlock unprecedented levels of efficiency and predictive capabilities.

Imagine IoT sensors embedded in your machinery automatically feeding real-time performance data (temperature, vibration, uptime) directly into your mobile ERP. AI algorithms within the ERP can then analyze this data to predict potential machine failures before they occur, allowing for proactive maintenance and minimizing costly downtime. This predictive maintenance, accessible and manageable via mobile devices, transforms reactive repairs into planned interventions. Furthermore, AI can optimize production schedules, material flow, and even energy consumption based on live data from the floor. Mobile ERP becomes the conduit through which this advanced intelligence is not only collected but also delivered to the hands of your workforce, enabling smarter, more autonomous, and ultimately more profitable manufacturing processes. The future is intelligent, interconnected, and undeniably mobile.

Choosing the Right Mobile ERP Partner for Your Small Manufacturing Business

The decision to implement Mobile ERP Solutions for Small Manufacturing Floor Management is a significant one, and choosing the right software vendor is as crucial as selecting the solution itself. With numerous options available, small manufacturers need a systematic approach to ensure they partner with a provider that truly understands their unique needs and challenges. This selection process should extend beyond just features and price.

Key criteria to consider include industry-specific functionalities: does the ERP system have modules and workflows tailored for discrete, process, or mixed-mode manufacturing relevant to your business? User-friendliness is paramount, especially for shop floor adoption; the mobile interface should be intuitive and require minimal training. Vendor support and training are also critical; look for a partner with a strong track record of post-implementation support and ongoing education. Scalability ensures the solution can grow with your business without requiring a costly migration later. Finally, transparent pricing and a clear understanding of the total cost of ownership (TCO) are essential for budgetary planning. A thorough evaluation, including demos and reference checks, will help you select a mobile ERP partner that will be a true asset to your small manufacturing business for years to come.

Success Stories: Real-World Impact of Mobile ERP on Small Manufacturers

While the theoretical benefits of Mobile ERP Solutions for Small Manufacturing Floor Management are compelling, their true power is best illustrated through real-world impact. Across various industries, small manufacturers have transformed their operations by embracing mobile ERP, moving from struggling with inefficiencies to thriving with optimized processes. Consider a custom metal fabrication shop that previously relied on paper travelers and manual inventory counts. Delays were common, and locating specific stock was a constant headache, often leading to wasted time and missed deadlines.

After implementing a mobile ERP system, their operators began scanning work orders at each stage of production, updating progress in real-time. Inventory personnel used tablets to conduct cycle counts in minutes, with data instantly updating stock levels. The result? A 20% reduction in production lead times, a 15% decrease in inventory holding costs, and a significant boost in on-time delivery rates, which directly led to increased customer satisfaction and repeat business. Similarly, a small food processing plant used mobile devices to log quality checks at every critical control point, ensuring regulatory compliance and reducing product recalls by over 50%. These aren’t isolated incidents; they are testaments to how targeted, mobile technology can unlock substantial efficiencies and drive growth for small manufacturing enterprises everywhere.

Addressing Common Misconceptions About ERP for Small Businesses

One of the biggest hurdles small manufacturers face when considering Mobile ERP Solutions for Small Manufacturing Floor Management is often rooted in misconceptions about ERP itself. Many believe that ERP systems are exclusively for large enterprises with massive budgets and dedicated IT departments. This perception, while perhaps true in the early days of ERP, is now largely outdated and prevents many small businesses from exploring solutions that could profoundly benefit them.

Modern ERP solutions, particularly those cloud-based and designed for small and medium-sized businesses (SMBs), are far more accessible and affordable than ever before. They often feature modular designs, allowing businesses to implement only the functionalities they need, with the option to add more as they grow. The “cost” of ERP needs to be weighed against the “cost of inaction” – the ongoing expenses of inefficiencies, errors, lost productivity, and missed opportunities stemming from outdated manual processes. Furthermore, the belief that ERP implementation is inherently disruptive is also often exaggerated. With proper planning, phased rollouts, and strong vendor support, the transition can be managed with minimal operational impact. Dispelling these myths is the first step toward embracing a technology that can genuinely revolutionize a small manufacturing business.

Conclusion: Embrace the Mobile Revolution on Your Manufacturing Floor

The journey of a small manufacturer is one of continuous adaptation and innovation. In an increasingly competitive global market, clinging to outdated, manual processes is no longer a viable strategy for sustained growth and profitability. The shift towards digital transformation is not just for the industrial giants; it’s a critical pathway for small manufacturing businesses looking to optimize their operations, empower their workforce, and secure their future. Mobile ERP Solutions for Small Manufacturing Floor Management offer a clear, actionable, and profoundly impactful route to achieve these goals.

By bringing real-time data collection, streamlined workflows, and comprehensive visibility directly to the hands of your shop floor personnel, mobile ERP eliminates inefficiencies, reduces errors, and provides the intelligence needed for agile decision-making. From inventory management and production tracking to quality control and supply chain integration, the benefits ripple across every aspect of your operation. It’s about moving beyond simply making products to intelligently orchestrating every step of their creation. Embracing this mobile revolution isn’t just an upgrade; it’s an investment in a more efficient, responsive, and ultimately more prosperous manufacturing future for your business. The time to mobilize your manufacturing floor is now.